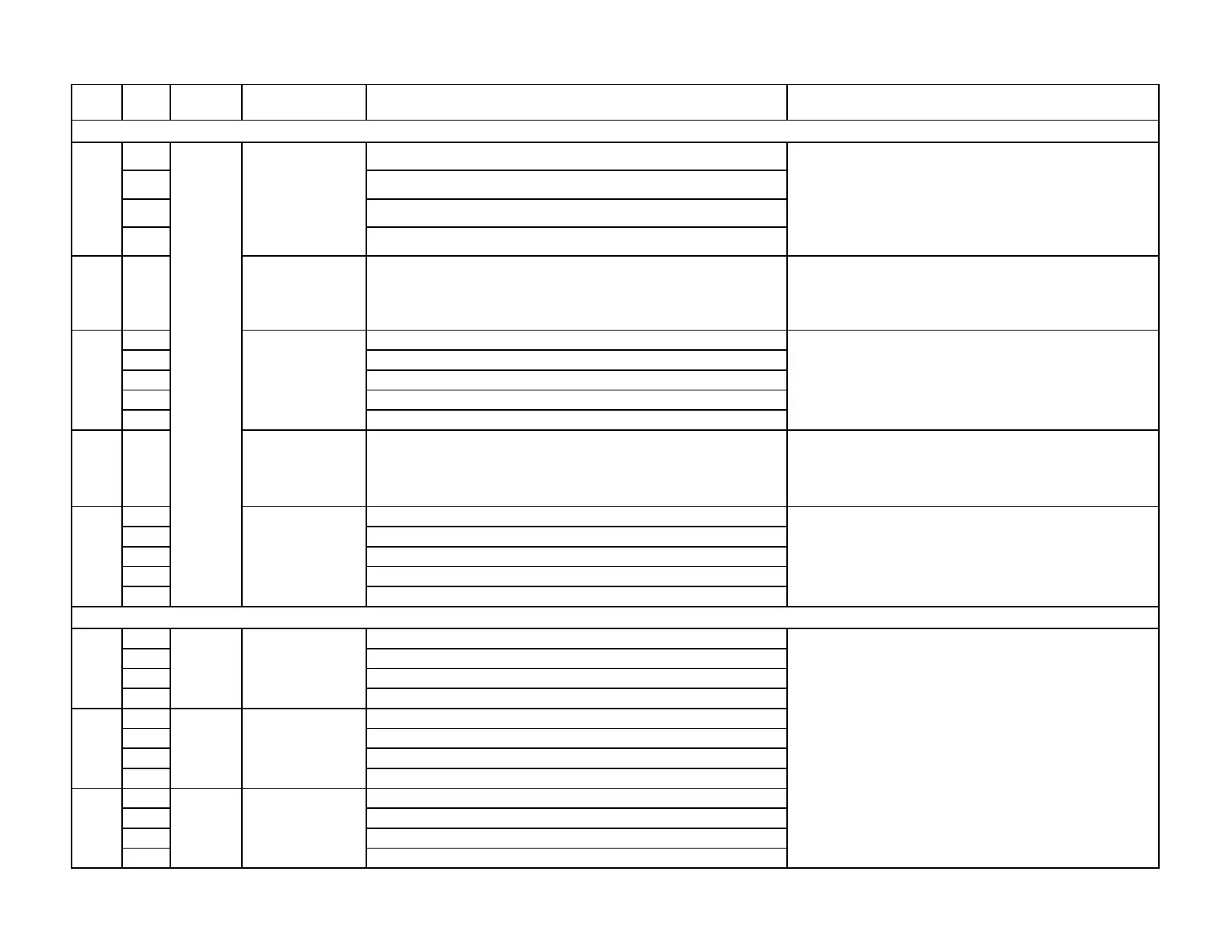

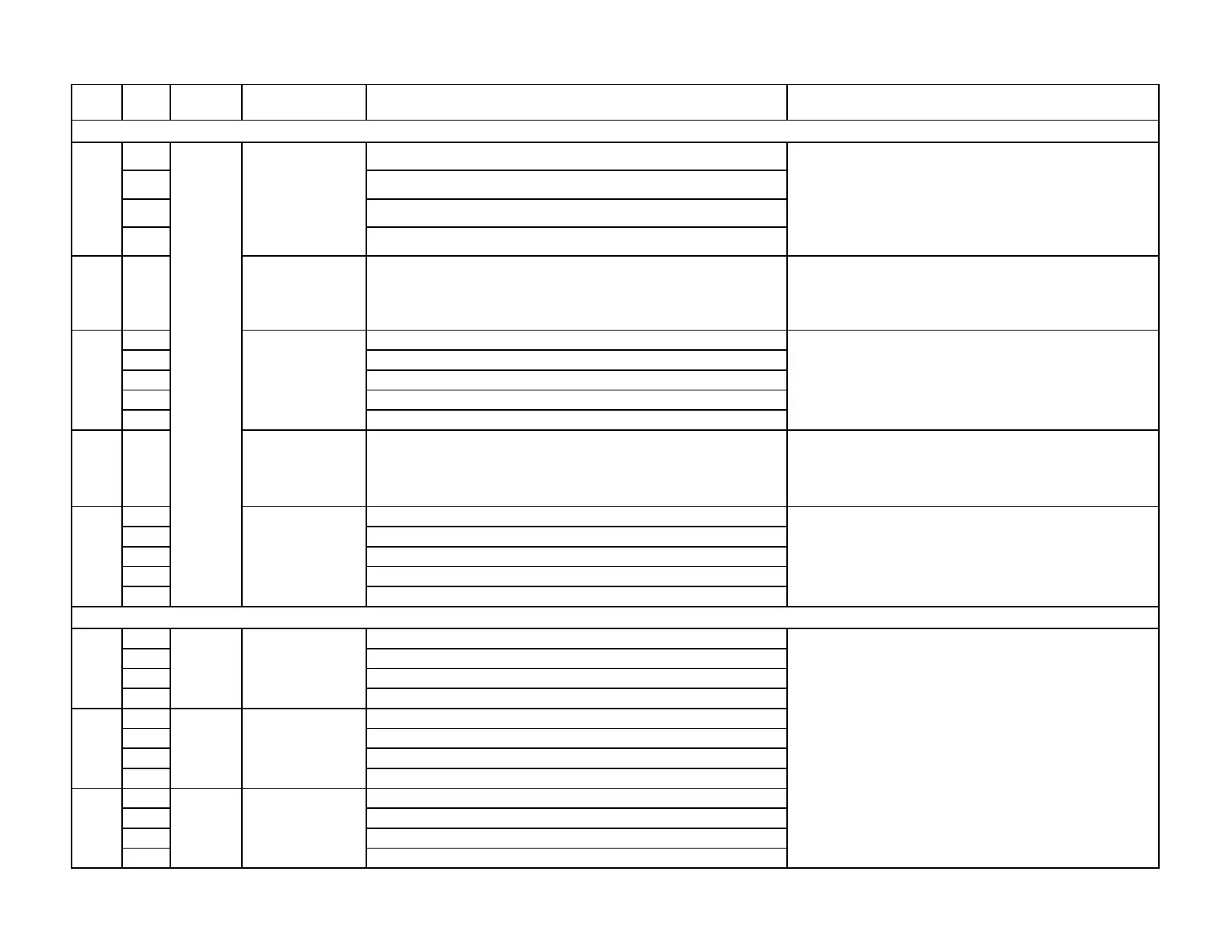

Device Display Meaning for the LMV5x System Corrective Action

20 Fault when calling the "ParAccess()" function

21 Written EEPROM block unequal RAM block

22 CRC of page is faulty

23 Matching fault µC1, µC2 when saving the error page

63 Any #

No display of

error (can only be

read out via

eBus)

Unit is error-free None

Any # Fault during restoring of lockout information

01 When reading from EEPROM (initialization)

02 When test writing in the initialization

03 No write access to error page in init.

04 Repetition counter "Internal fault" has elapsed

71 Any # Manual Lockout Lockout was made manually via contact

This lockout occurs when escape and enter on the AZL

are pressed simultaneously. This lockout also occurs

when the remote reset X4-01.4 is energized when an

alarm condition does not exist.

Any # Plausibility fault in connection with fault entry

01 Fault in "seterr()"

02 Fault in "seterr()"

03 Fault in "error_manager()"

04 Fault in "storeerr()"

Any # Basic unit has detected wrong state of the auxiliary 3 actuator

01 CRC error

02 Key error main loop counter

03 No feedback for max. number

Any # Basic unit has detected wrong state of the air actuator

01 CRC error

02 Key error main loop counter

03 No feedback for max. number

Any # Basic unit has detected wrong state of the gas actuator

01 CRC error

02 Key error main loop counter

03 No feedback for max. number

80

81

82

1) This fault occurs when an un-addressed actuator is

connected to the CANBus. Addressing the actuator

should eliminate the fault.

2) Check CANBus cabling. Ensure that all cable shields

(screens) which are located in the cable sheath are

terminated correctly at each actuator, O2 module, and

at the LMV5x...

3) Check each CANBus connector to ensure proper

termination (no conductors exposed on the back of the

plug)

4) If fault occurs sporadically: Reduce electrical noise.

5) If fault occurs constantly: Replace actuator according

to diagnostic code.

Internal Fault

Basic Unit

Aux 3

Actuator

72

Fault with Base Unit (LMV5)

Internal Fault

Basic Unit

If fault occurs sporadically, reduce electrical noise.

If fault occurs continuously, replace LMV5.

Fault with Connected Actuators

LMV5

70

61

1) Reset the LMV5

2) If fault occurred after changing a parameter, check

the parameters that were last changed.

3) If fault cannot be rectified by the reset: Restore

parameters form the AZL to the LMV5

4) Replace the LMV5

Internal Fault

Basic Unit

If fault occurs sporadically, reduce electrical noise.

If fault occurs continuously, replace LMV5.

Fault Feedback

Aux Actuator 3

Fault Feedback

Air Actuator

Fault Feedback

Gas (Oil) Actuator

Air

Actuator

Gas (Oil)

Actuator

Section 7 Page 39 SCC Inc.

Loading...

Loading...