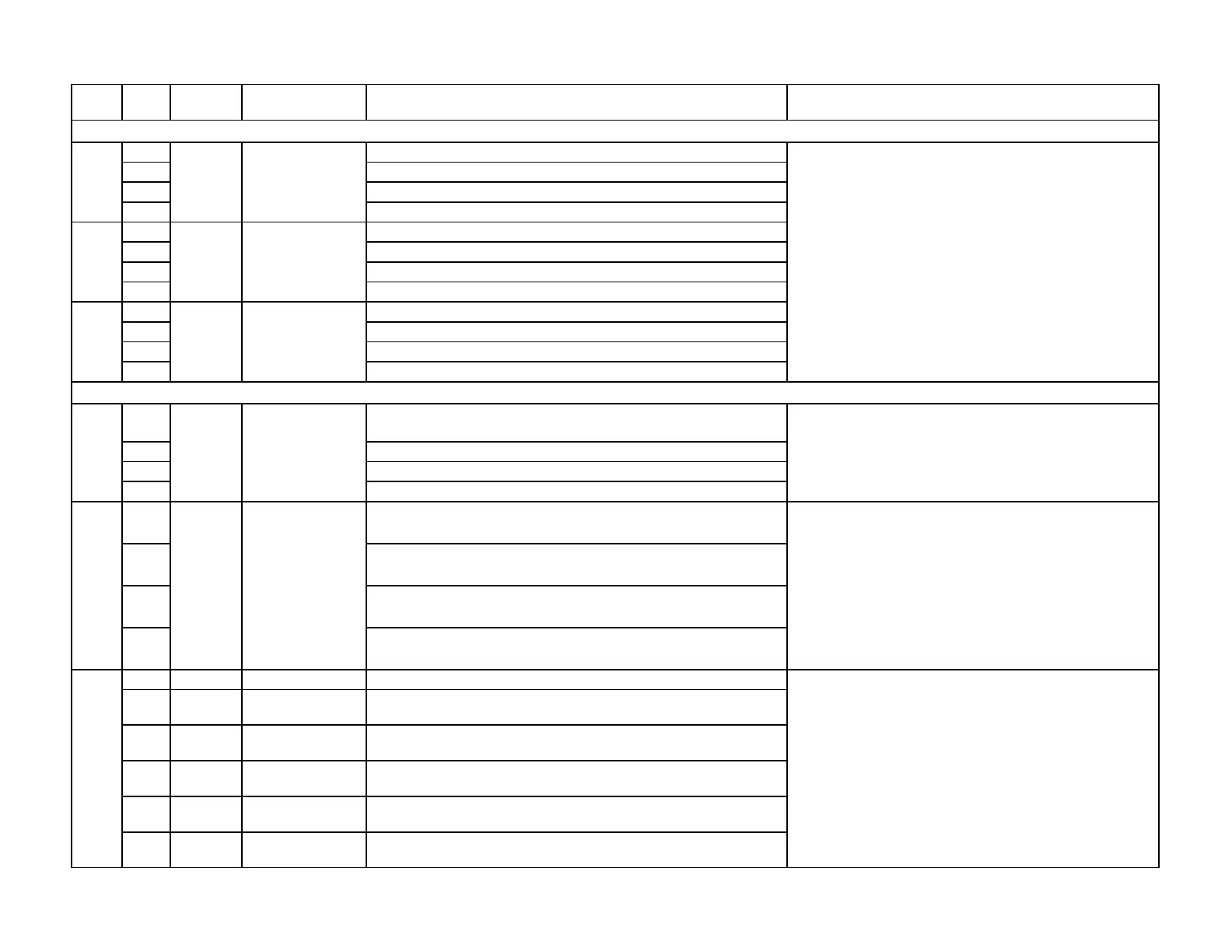

Device Display Meaning for the LMV5x System Corrective Action

Any # Basic unit has detected wrong state of the oil actuator

01 CRC error

02 Key error main loop counter

03 No feedback for max. number

Any # Basic unit has detected wrong state of the auxiliary 1 actuator

01 CRC error

02 Key error main loop counter

03 No feedback for max. number

Any # Basic unit has detected wrong state of the auxiliary 2 actuator

01 CRC error

02 Key error main loop counter

03 No feedback for max. number

Any #

Basic unit has detected wrong state of the internal load

controller

01 CRC error

02 Key error main loop counter

03 No feedback for max. number

Any # Basic unit has detected wrong state of the AZL

01 CRC error

02 Key error main loop counter

03 No feedback for max. number

Any # All Plausibility fault NMT

01 Actuator

Fault Feedback

Undefined fault class of actuator

02 LMV5

Fault Feedback

Undefined fault class of load controller

03 AZL5

Fault Feedback

Undefined fault class of AZL5

04

VSD

Fault Feedback

Undefined fault class of VSD module

05 O2 Mod.

Fault Feedback

Undefined fault class of O2 module

If fault occurs sporadically, reduce electrical noise.

If fault occurs constantly, replace the defective unit (see

diagnostic code) or the LMV5.

Note: The internal load controller and VSD module are

part of the LMV5.

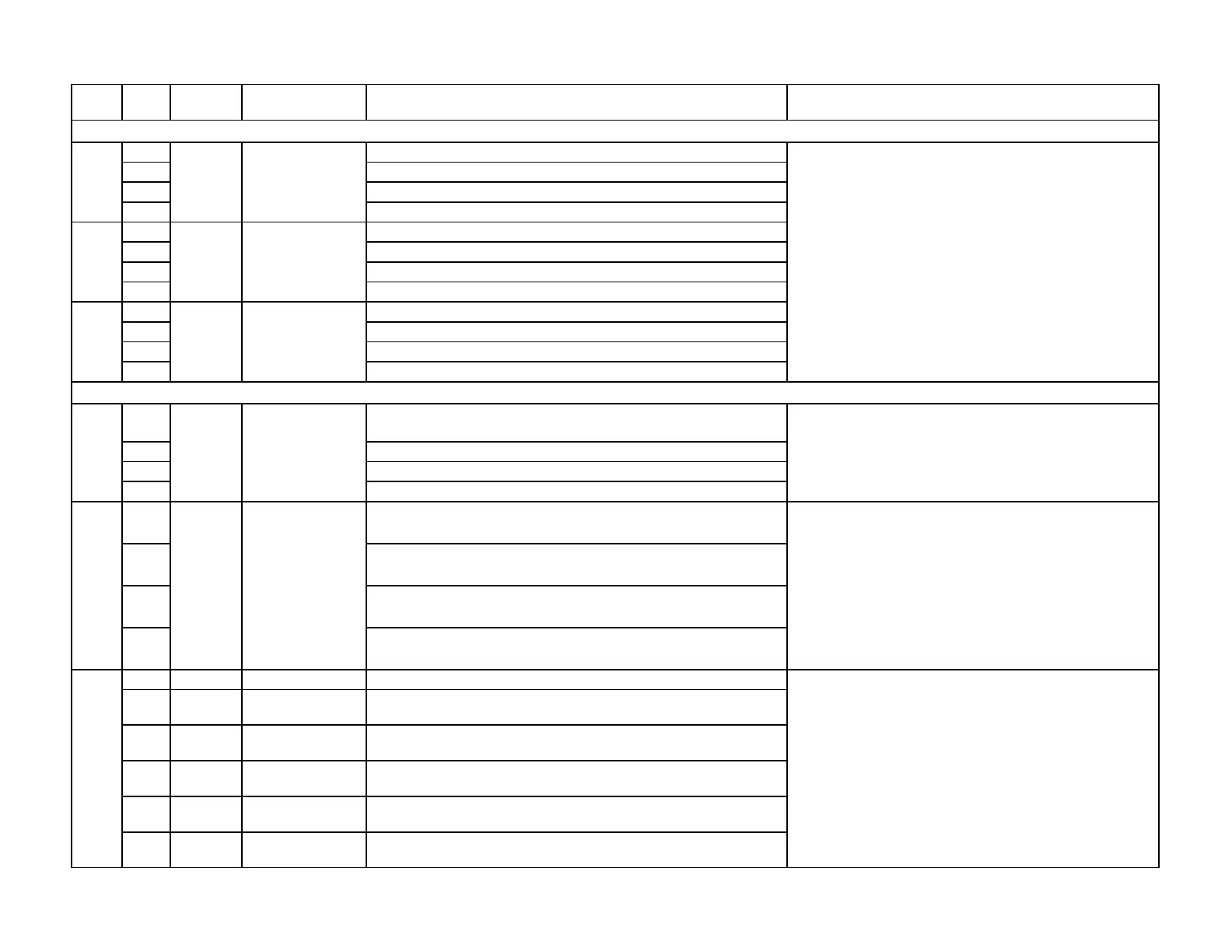

Oil

Actuator

83

84

Aux 2

Actuator

87

Fault with Connected Actuators

85

1) This fault occurs when an un-addressed actuator is

connected to the CANBus. Addressing the actuator

should eliminate the fault.

2) Check CANBus cabling. Ensure that all cable shields

(screens) which are located in the cable sheath are

terminated correctly at each actuator, O2 module, and

at the LMV5x...

3) Check each CANBus connector to ensure proper

termination (no conductors exposed on the back of the

plug)

4) If fault occurs sporadically: Reduce electrical noise.

5) If fault occurs constantly: Replace actuator according

to diagnostic code.

Fault Feedback

Oil Actuator

Aux 1

Actuator

Fault Feedback

Aux Actuator 1

If fault occurs sporadically, reduce electrical noise.

If fault occurs continuously, replace LMV5.

Fault Feedback

AZL5

1) Check CANBus cabling. Ensure that all cable shields

(screens) which are located in the cable sheath are

terminated correctly at each actuator, O2 module, and

at the LMV5

2) Check each CANBus connector to ensure proper

termination (no conductors exposed on the back of the

plug)

3) If fault occurs sporadically: Reduce electrical noise.

4) If fault occurs constantly: Replace AZL5...

Fault Feedback

Aux Actuator 2

Fault with Base Unit (LMV5) or AZL5

LMV5

AZL5

88

Fault Feedback

Load Controller

86

Section 7 Page 40 SCC Inc.

Loading...

Loading...