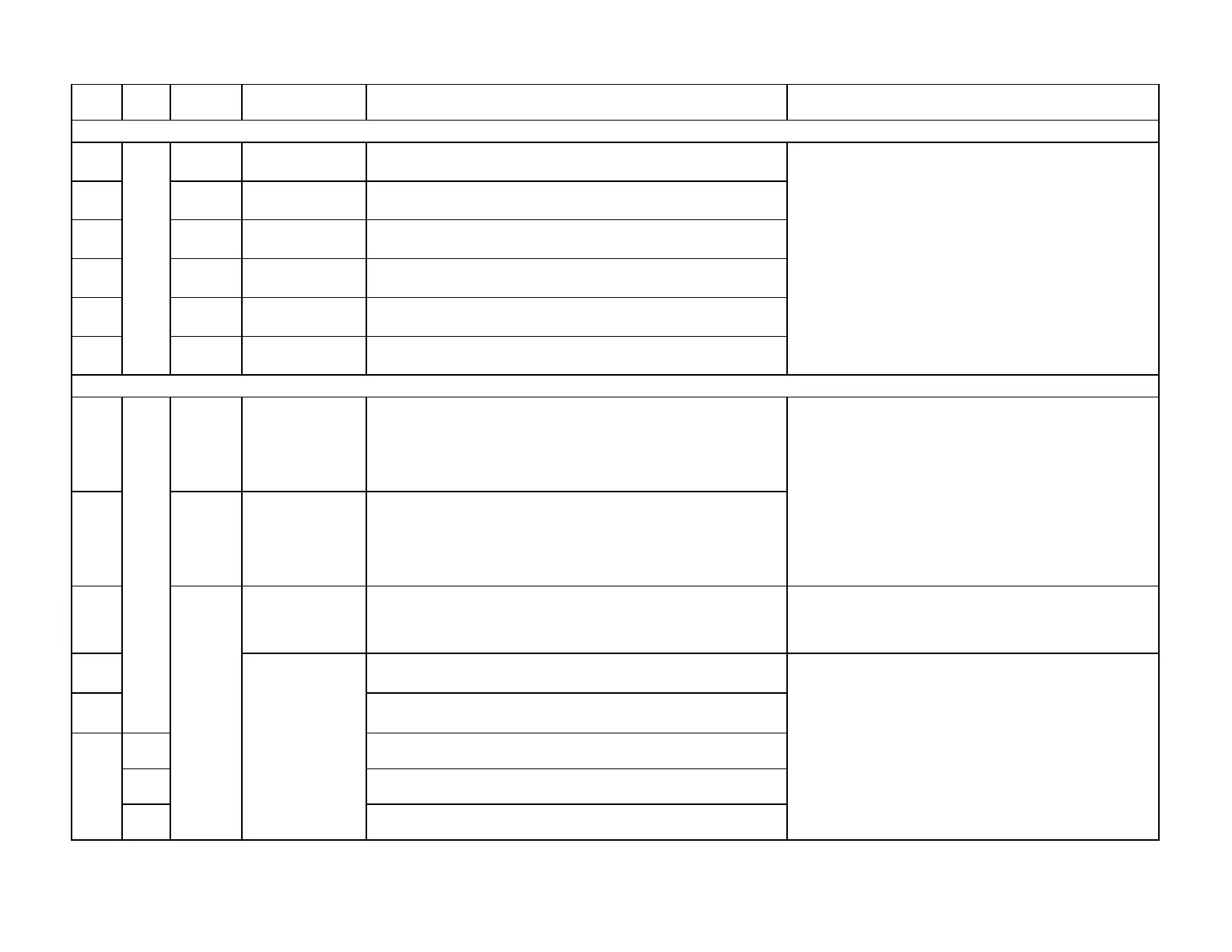

Device Display Meaning for the LMV5x System Corrective Action

90

Aux 3

Actuator

Fault Feedback

Aux Actuator 3

Basic unit has detected a ROM-CRC error

on the auxiliary 3 actuator when checking its feedback signal

91

Air

Actuator

Fault Feedback

Air Actuator

Basic unit has detected a ROM-CRC error

on the air actuator when checking its feedback signal

92

Gas (Oil)

Actuator

Fault Feedback

Gas (Oil) Actuator

Basic unit has detected a ROM-CRC error

on the gas actuator when checking its feedback signal

93

Oil

Actuator

Fault Feedback

Oil Actuator

Basic unit has detected a ROM-CRC error

on the oil actuator when checking its feedback signal

94

Aux 1

Actuator

Fault Feedback

Aux Actuator 1

Basic unit has detected a ROM-CRC error

on the auxiliary 1 actuator when checking its feedback signal

95

Aux 2

Actuator

Fault Feedback

Aux Actuator 2

Basic unit has detected a ROM-CRC error

on the auxiliary 2 actuator when checking its feedback signal

96 LMV5

Fault Feedback

Load Controller

Basic unit has detected a ROM-CRC error

on the load controller when checking its feedback signal

97 AZL5

Fault Feedback

AZL

Basic unit has detected a ROM-CRC error

on the AZL when checking its feedback signal

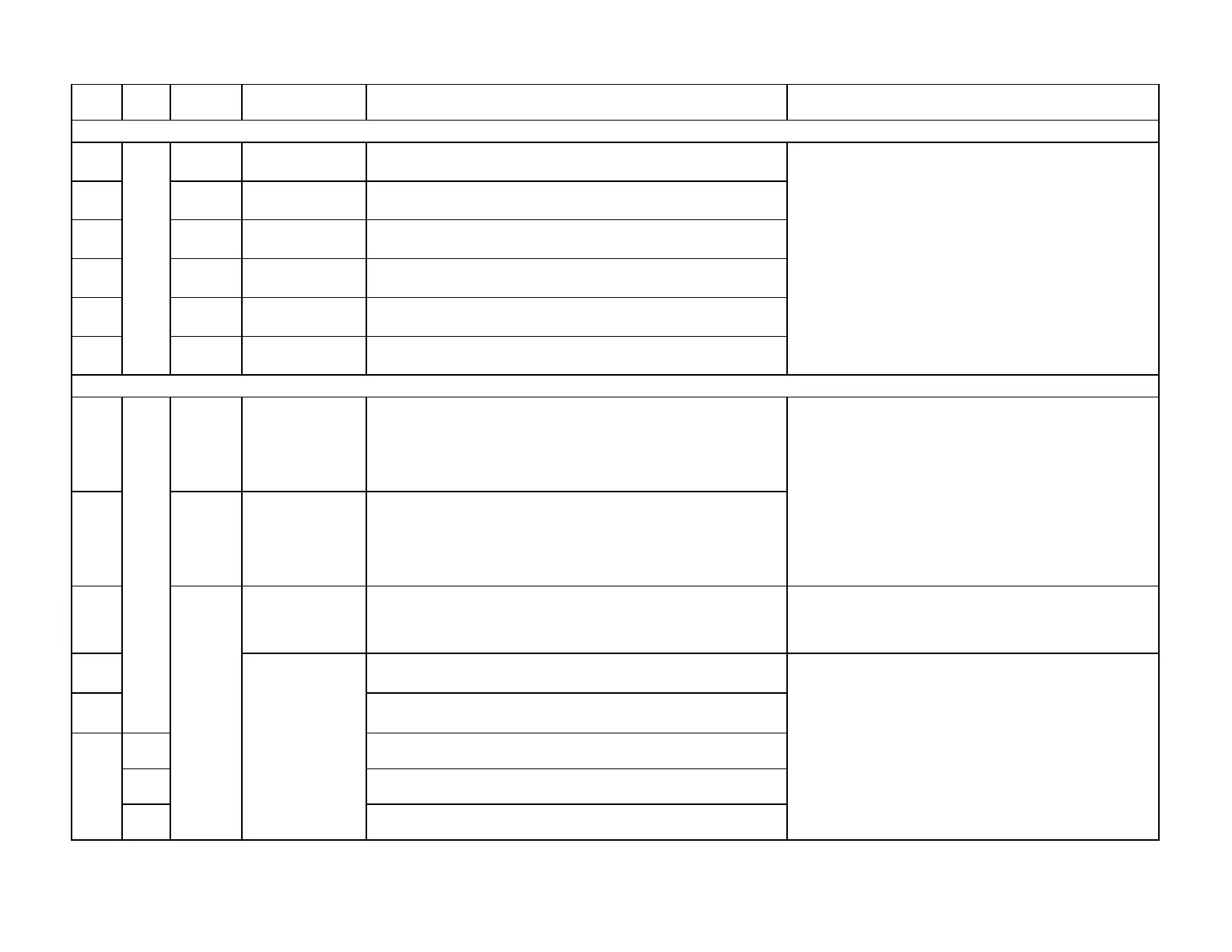

98

Fault two equal

Addresses

There are several components with the same address

on the CAN bus (CAN overflow)

Check to see if two actuators are addressed identically.

If so, erase the address on the incorrect actuator (hold

red button down about 10 seconds) and re-address.

99

CANBus OFF. A CANBus user (actuators, O2 module)

switches the CANBus to OFF mode.

9A

CAN warning level. Fault probably occurred when connecting

or disconnecting a CANBus user

Any # Overflow of CAN queue

01 Overflow of RX queue

02 Overflow of TX queue

Fault with Base Unit (LMV5), or AZL5

9B

Internal Fault

Basic Unit

1) Check CANBus cabling. Ensure that all cable shields

(screens) which are located in the cable sheath are

terminated correctly at each actuator, O2 module, and

at the LMV5x...

2) Check each CANBus connector to ensure proper

termination (no conductors exposed on the back of the

plug)

3) If fault occurs sporadically: Reduce electrical noise.

4) If fault occurs constantly: Replace AZL.., LMV5

Fault with Connected actuators

1) Check CANBus cabling. Ensure that all cable shields

(screens) which are located in the cable sheath are

terminated correctly at each actuator, O2 module, and

at the LMV5x...

2) Check each CANBus connector to ensure proper

termination (no conductors exposed on the back of the

plug)

3) If fault occurs sporadically: Reduce electrical noise.

4) If fault occurs constantly: Replace actuator according

to diagnostic code.

Any #

1) Check CANBus cabling. Ensure that all cable shields

(screens) which are located in the cable sheath are

terminated correctly at each actuator, O2 module, and

at the LMV5x...

2) Check each CANBus connector to ensure proper

termination (no conductors exposed on the back of the

plug)

3) If fault occurs sporadically: Reduce electrical noise.

4) If fault occurs constantly: Replace actuator according

to diagnostic code.

Any #

All

Section 7 Page 41 SCC Inc.

Loading...

Loading...