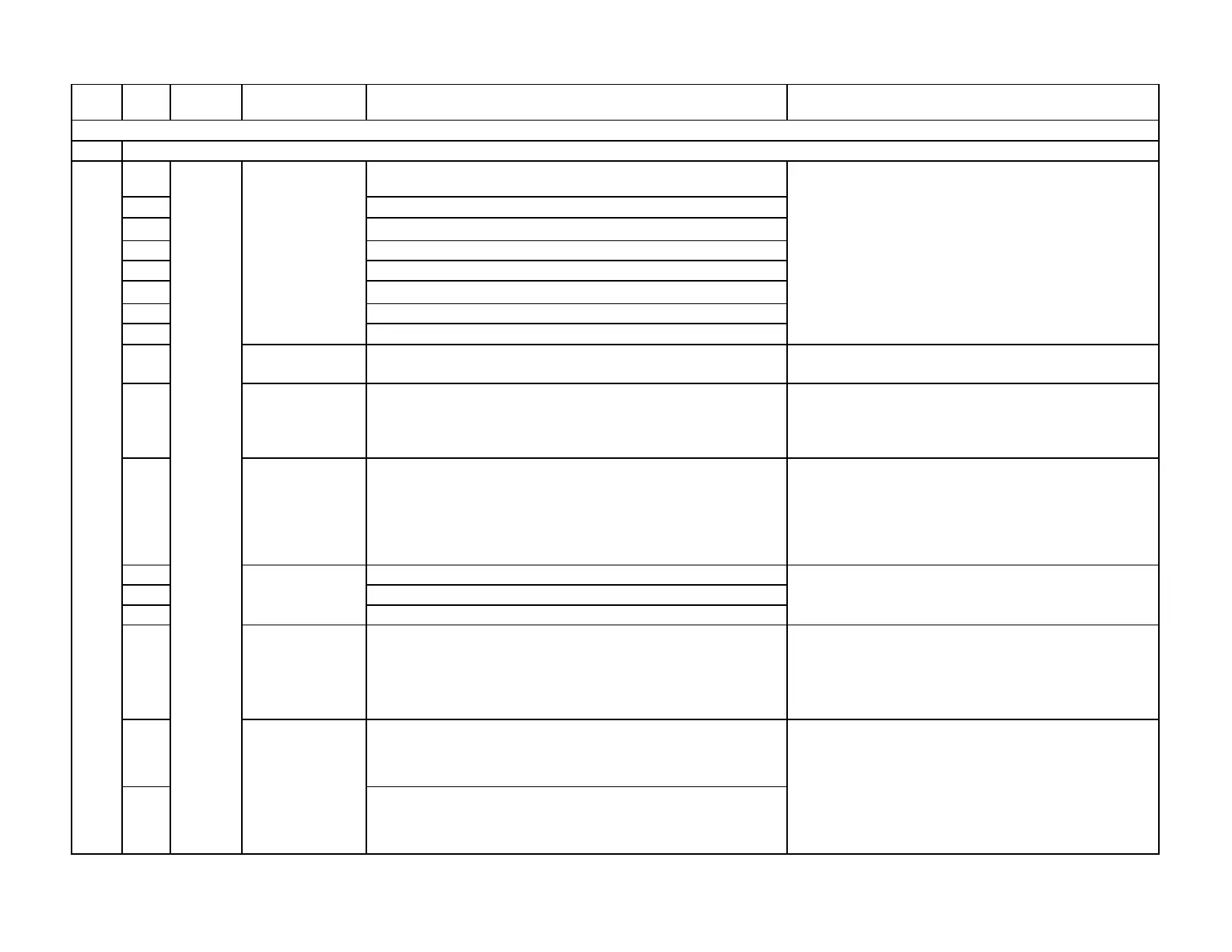

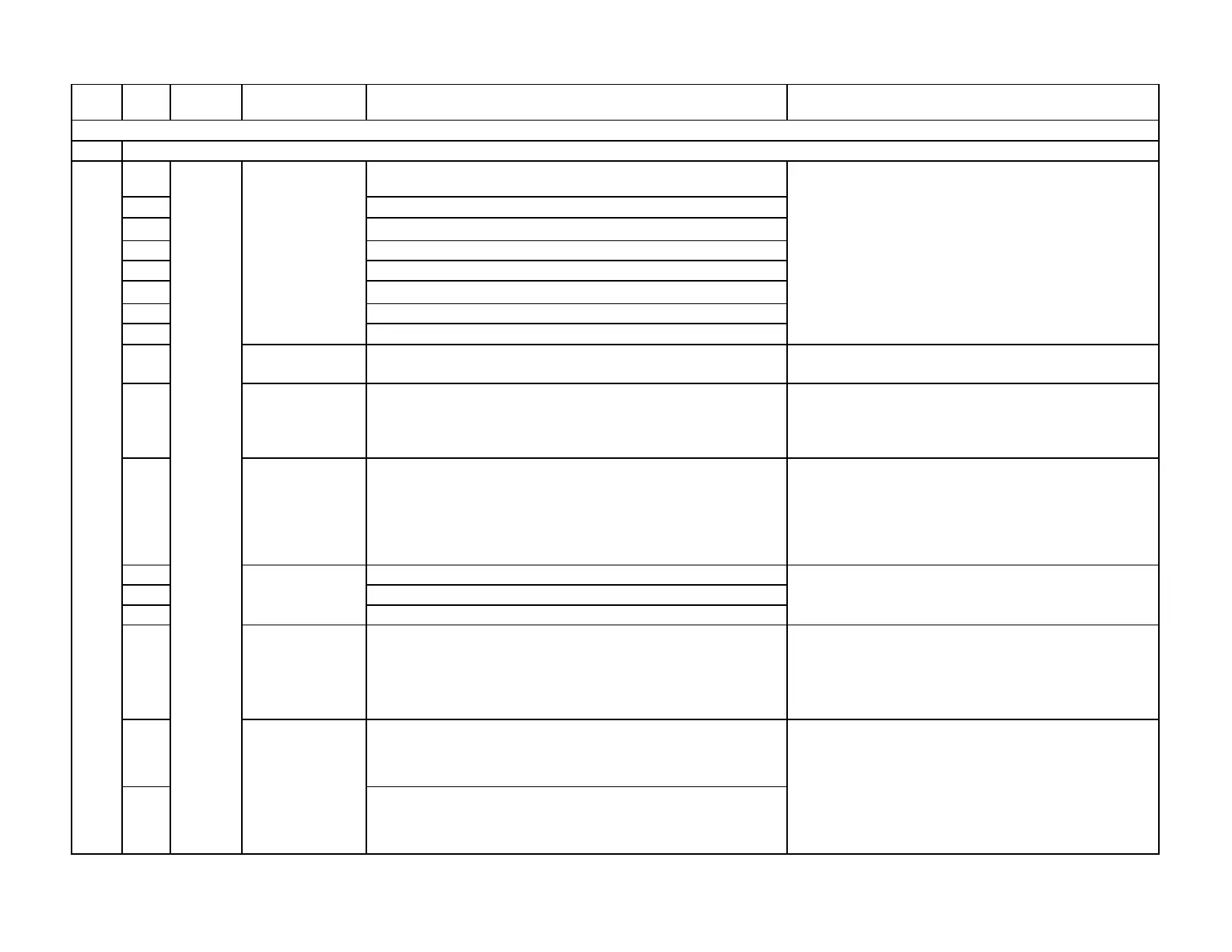

Device Display Meaning for the LMV5x System Corrective Action

A0

Any #

Air actuator has detected own fault and reported it to the basic

unit. Type of fault: See diagnostic code

01 CRC fault during ROM test

02 CRC fault during RAM test

04 Fault during key value check

05 Error code for time block overflow

07 Sync fault or CRC fault

08 Error code for main loop counter

09 Fault during stack test

0C

Overtemperature

Air Actuator

Temperature warning and shutdown

Check the temperature of the air actuator. The max.

temperature 140 °F.

0D

Internal Fault Air

Actuator

Actuator turns in the wrong direction

Verify that the air damper is not stuck. A stuck air

damper will cause the actuator to trip on overcurrent.

During this short trip the actuator can be momentarily

pushed backwards by torsional effects.

0E

Ramp time too

short

Air Actuator

Actuator operates with too short a ramp time,

or with an angular rotation that is too long for the ramp time

1) Match ramp time to the slowest connected actuator

(SQM48.4 - 30 sec, SQM48.6 - 60sec, SQM9 - 30 sec)

2) Check the CANBus power supply. Verify fuses FU2

and FU3 are ok. Verify CANBus is not overloaded (see

wiring section).

10 Timeout during A/D conversion

11 Fault during ADC test

12 Fault during A/D conversion

13

Position Fault Air

Actuator

Actuator is outside the valid angular

rotation (0-90°) or linearization data are faulty

Check to see if actuator is within the valid positioning

range (0-90°). When the actuator is not powered, it

could be moved out of the valid positioning range. Take

power off the actuator and position shaft back within the

valid positioning range.

15 CAN fault

16 CRC fault of a parameter page

Fault with Connected Actuators

Air

Actuator

Internal Fault Air

Actuator

A1

1) Check CANBus cabling. Ensure that all cable shields

(screens) which are located in the cable sheath are

terminated correctly at each actuator, O2 module, and

at the LMV5x...

2) Check each CANBus connector to ensure proper

termination (no conductors exposed on the back of the

plug)

3) If fault occurs sporadically: Reduce electrical noise.

4) If fault occurs constantly: Replace air actuator

See diagnostic codes for A1 error codes. These diagnostic codes are identical, except they apply to the Auxiliary 3 Actuator.

1) Check CANBus cabling. Ensure that all cable shields

(screens) which are located in the cable sheath are

terminated correctly at each actuator, O2 module, and

at the LMV5x...

2) Check each CANBus connector to ensure proper

termination (no conductors exposed on the back of the

plug)

1) If fault occurs sporadically, reduce electrical noise.

2) If fault occurs constantly, replace air actuator.

Internal Fault Air

Actuator

Internal Fault Air

Actuator

Section 7 Page 42 SCC Inc.

Loading...

Loading...