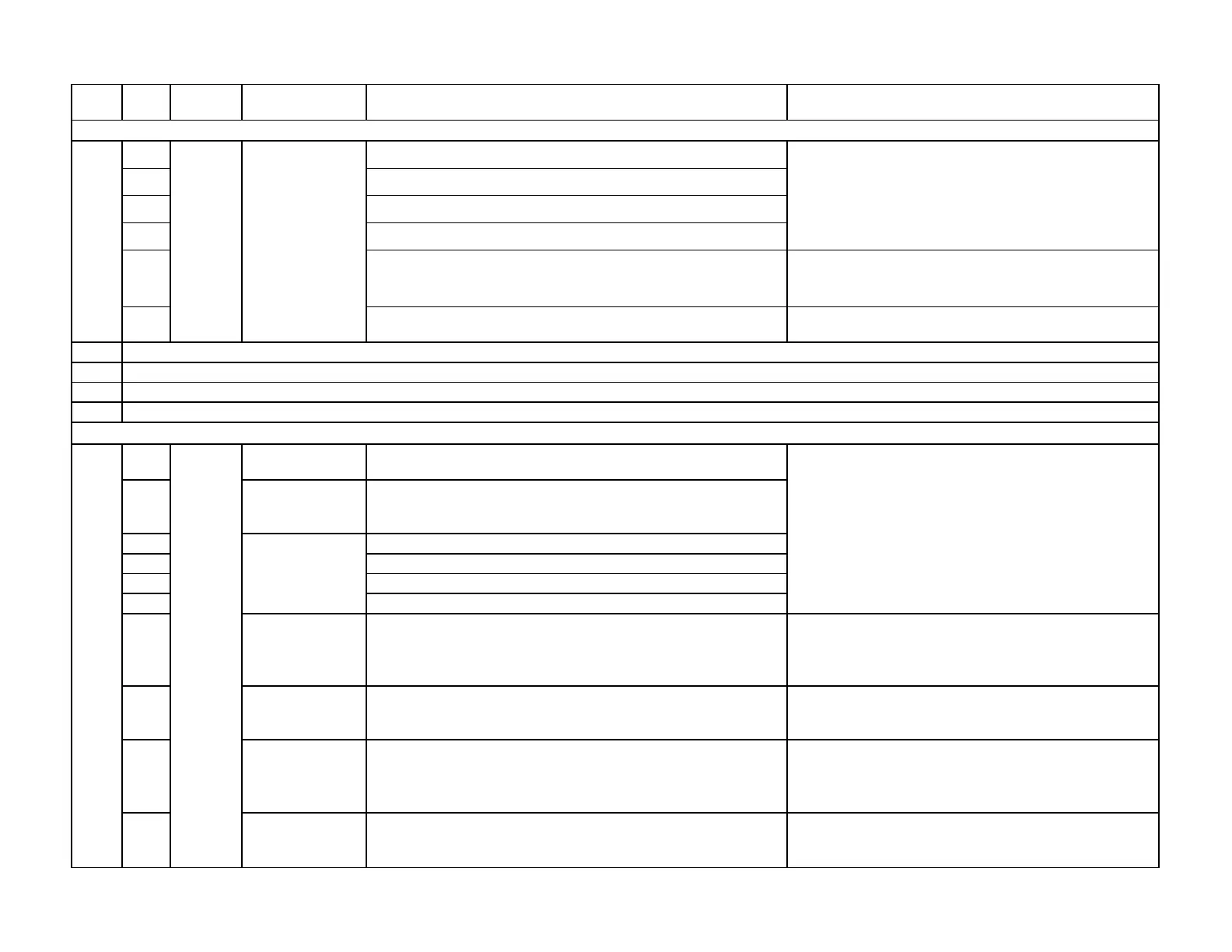

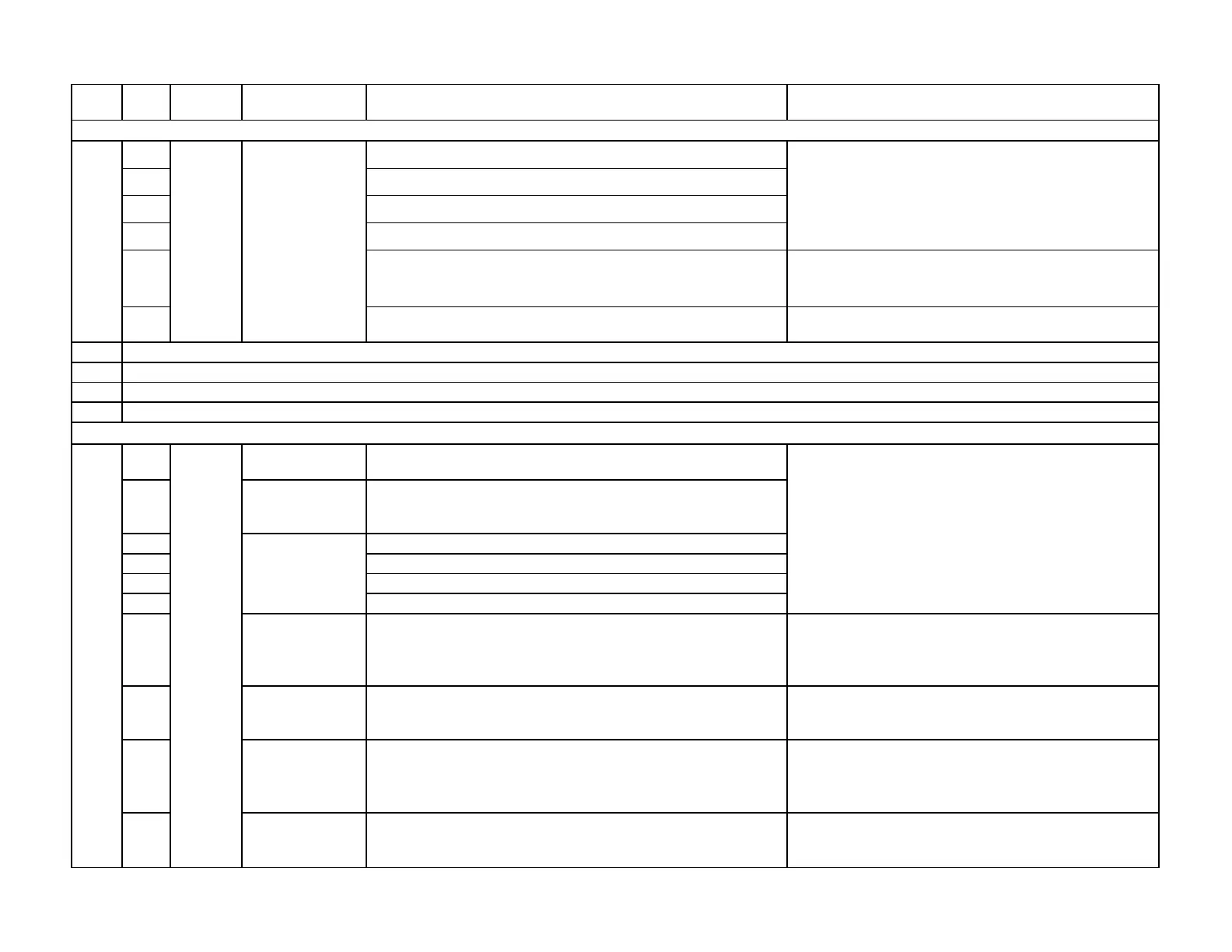

Device Display Meaning for the LMV5x System Corrective Action

17 Page too long open

18 Page disrupted

19 Invalid parameter access

1B Fault during copying of parameter page

1E

External plausibility fault. This type of fault covers possible

faults occurring due to invalid presettings in the drive

commands. In response, the presettings will be ignored

1) Check the paramters related to special positions.

The special positions of each activated actuator should

be programmed between 0 and 90 degrees.

1F

Internal plausibility fault. This type of fault covers possible

faults that can occur due to strong electrical noise

1) If fault occurs sporadically: Reduce electrical noise.

A2

A3

A4

A5

Any # -

Internal load controller has detected a fault. Type of fault: See

10

No actual Value

Slope at End of

-

12 Invalid XP identified

13 Invalid TN identified

14 TU longer than identification time

15 Invalid TV identified

16

Timeout with

Adaption

Timeout during observation time

PV (Process Varible) is not changing in response to

firing rate during the adaption time. Adaption times out

due to lack of change in the measured PV. Check

sensor and thermal system.

17

Shock Protection

A warning indicating that the Cold Start Thermal Shock

Protection (CSTP) is activated

This can be deactivated, if desired. See parameters

concerning the load controller in the settings section.

18

Timeout with

Adaption

Timeout during delivery of adaption rate and while process is

being watched

PV (Process Varible) is not changing in response to

firing rate during the adaption time. Adaption times out

due to lack of change in the measured PV. Check

sensor and thermal system.

22

Setpoint Temp

Controller above

The current setpoint (W1, W2, W3) is above the value of the

internal temperature limiter.

Raise the value of the internal temperaure limiter or

decrease the current setpoint.

See diagnostic codes for A1 error codes. These diagnostic codes are identical, except they apply to the Gas (Oil) Actuator.

See diagnostic codes for A1 error codes. These diagnostic codes are identical, except they apply to the Auxiliary 2 Actuator.

Fault with Base Unit (LMV5) Internal Load Controller

1) Reset the LMV5

2) If fault occurred after changing a parameter, check

the parameters that were last changed.

3) If fault cannot be rectified by the reset: Restore

parameters form the AZL to the LMV5

4) If fault occurs continuously, replace LMV5.

A1

If fault occurs sporadically, reduce electrical noise.

If fault occurs continuously, replace LMV5.

A6

LMV5

Load

Module

See diagnostic codes for A1 error codes. These diagnostic codes are identical, except they apply to the Oil Actuator.

See diagnostic codes for A1 error codes. These diagnostic codes are identical, except they apply to the Auxiliary 1 Actuator.

Adaption invalid

Fault with Connected Actuators

Internal Fault Air

Actuator

Air

Actuator

Section 7 Page 43 SCC Inc.

Loading...

Loading...