Image processing

4.2 Code verification

SIMATIC MV420 / SIMATIC MV440

42 Operating Instructions, 04/2013, A5E02371045-06

4.2 Code verification

4.2.1 Overview

Verification

A generally accepted axiom in the implementation of traceability says: The data matrix code

will never be better than it was at the time it left the marking device.

During the marking process, verification ensures that the marking is correctly applied.

Verification makes sure that corrections can be made to the marking procedure before it

leaves a range of tolerance and produces unusable or incomplete markings.

Marking quality

To recognize and ensure the readability and quality of a marking, a verifier is required

instead of a pure code reader.

A simple code reader outputs the result read or not read and does not provide any data to

identify trends relating to the marking device or the operator or to inform the operator of

potential read errors.

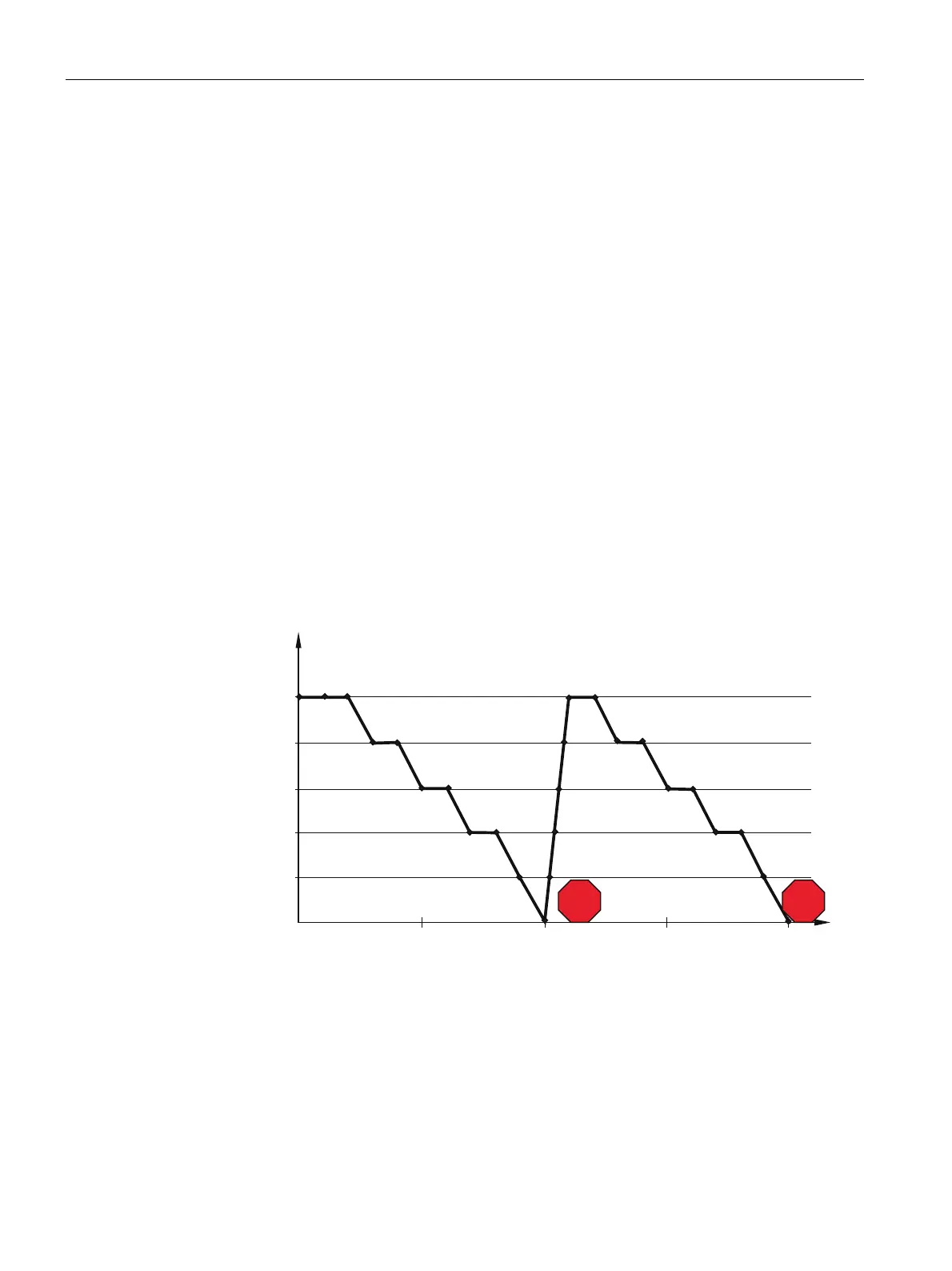

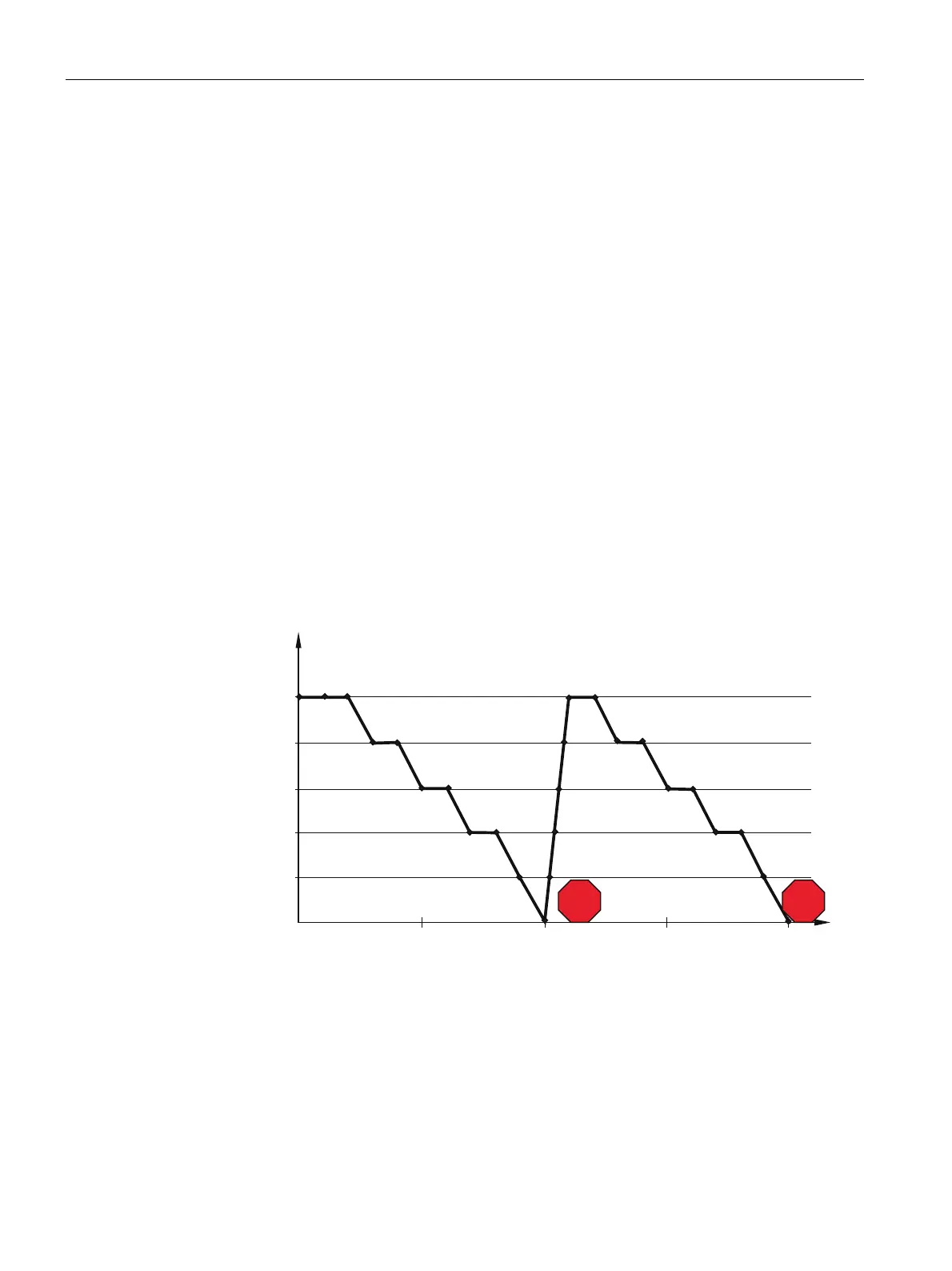

0DUNLQJTXDOLW\

1XPEHURIPDUNHGSDUWV

1RWUHDG

Figure 4-2 Sequence involved in marking quality when using a reader

The verifier assigns a quality grade from 4 to 0 to the readable markings. This grade informs

the marking device or operator when preventive maintenance is required. Based on this

knowledge, maintenance can be planned at a suitable time before the machine actually

becomes defective.

Loading...

Loading...