Configuration

5.2 Configuring workflow

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

115

● All required forces can be achieved at the required velocities.

● Overload phases of the duty cycle must not lead to shutdown by the temperature

monitoring.

In addition to the requirements from the duty cycle, mechanical installation conditions may

influence the choice of motor. The same motor forces may often be generated by different

types of primary sections.

If several primary sections are involved in the force generation of the axis, the values for the

maximum forces and rated forces of the individual motors must be added. For a gantry axis

with uneven distribution of the weight, the distribution of force among the individual motors is

not even. In this case, the force requirements on the individual motors must be considered

separately.

Motor-velocity-characteristic

The first two items are used for a preselection of the possible primary sections. If some

constraints such as the machining forces and frictional forces are not exactly known, it is

best to plan with larger margins.

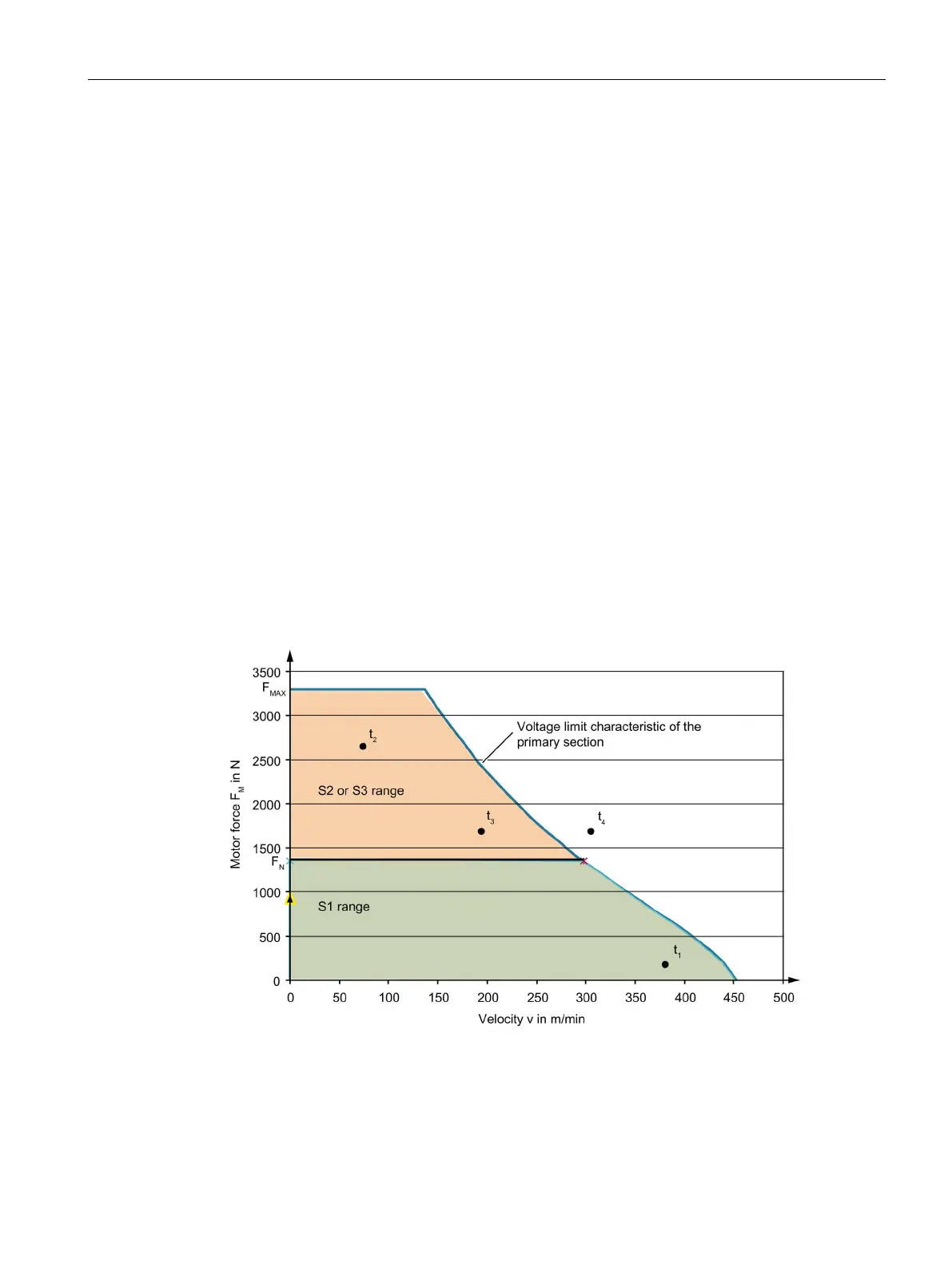

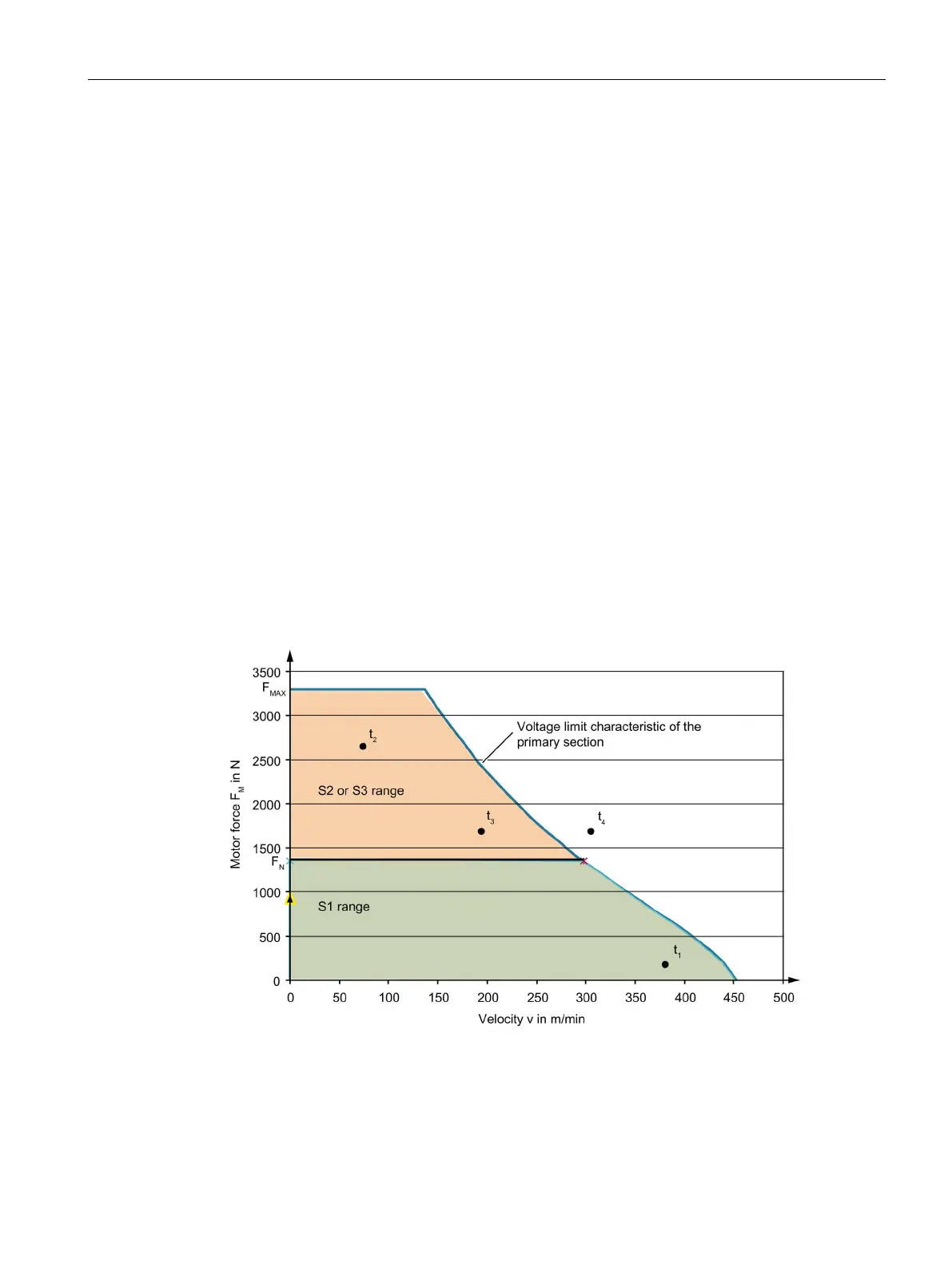

To determine whether a primary section actually fulfills the requirements from the duty cycle,

the motor force - velocity characteristic curve, which results from the required sequence of

motion and the motor force - time diagram, is required. In this case, only the absolute values

for motor force and velocity are decisive, not the directions. All points of the motor force -

velocity characteristic curve must be below the force - speed characteristic curve of the

primary section that is specified in the data sheets.

Figure 5-9 Example for points of a motor force - velocity characteristic curve in comparison with the

force - velocity characteristic curve of the primary section

Loading...

Loading...