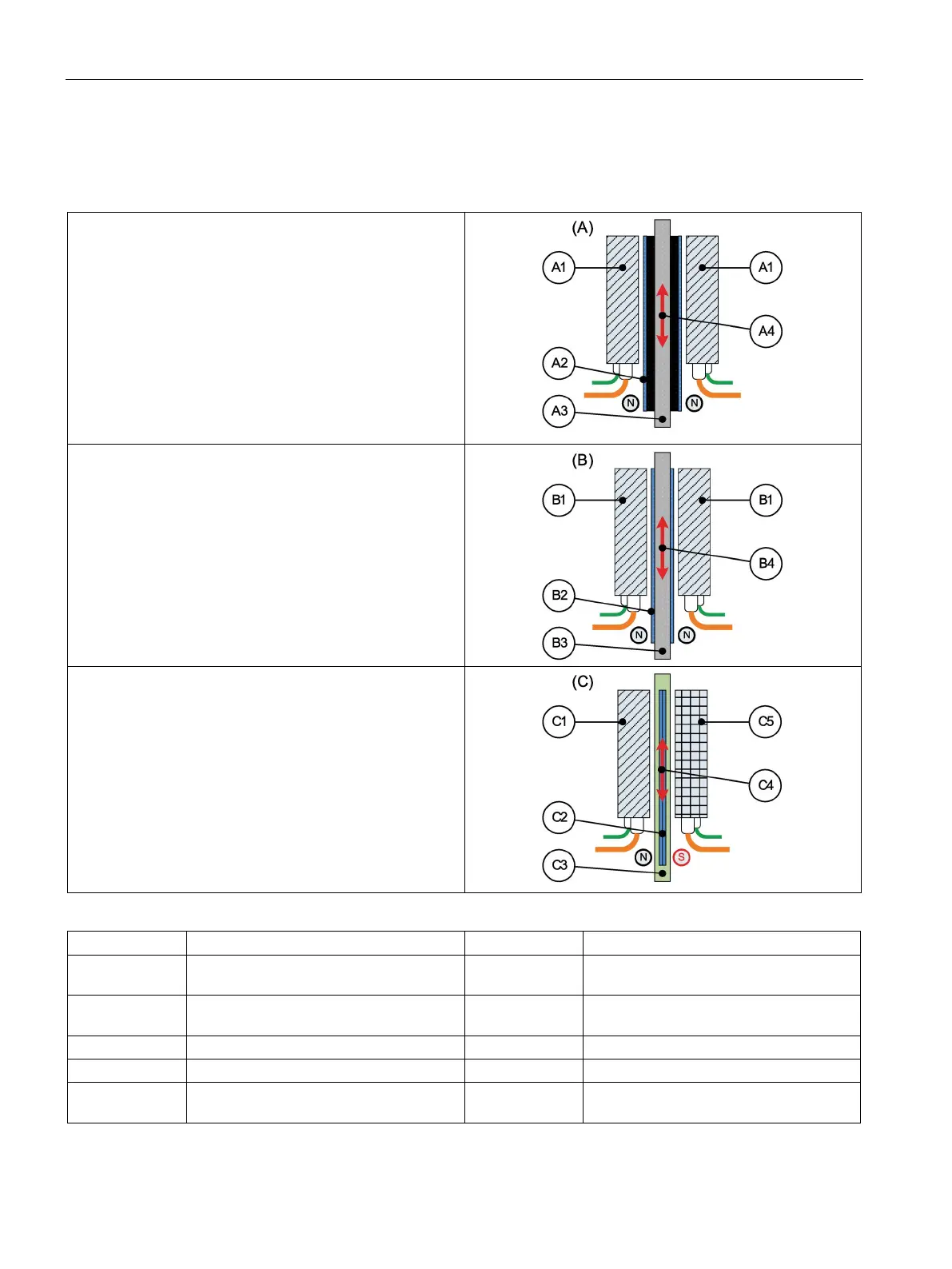

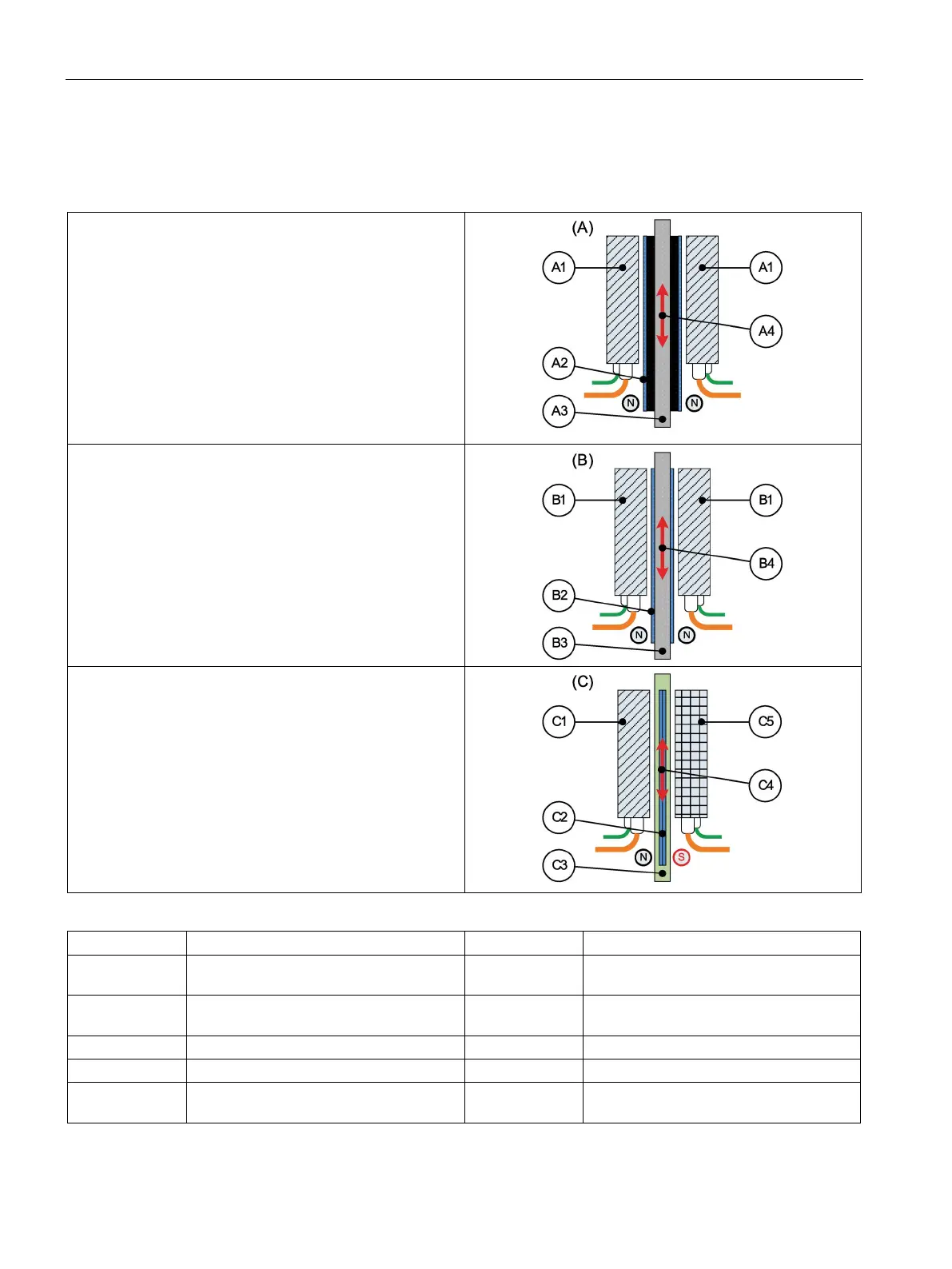

Coupled motors

10.2 Master and stoker

1FN3 linear motors

580 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

The following versions exist for designing double-sided motors:

The secondary section support is a plate with bolted-on

standard secondary section segments.

The support plate can be made of a magnetically active or

inactive material (e.g. aluminum, fiberglass reinforced

plastic).

Two standard primary sections are energized.

Compared with single-sided:

• More compact design

• Little additional cost for design

• Low mass reduction

The secondary section support is an especially prepared

plate with single magnets stuck on both sides.

The support plate must be made of magnetically active

material (iron, steel) for the magnetic return path.

Two standard primary sections are energized.

Compared with single-sided:

• Medium additional cost for design

• Medium mass reduction

The secondary section support is a plate with embedded

single magnets.

The support plate can be made of a magnetically inactive

material (e.g. aluminum, fiberglass reinforced plastic).

One standard primary section and one primary section with

an inverse winding (inverse magnetic pole layout) are

energized.

Compared with single-sided:

• Highest additional cost for design

• Highest mass reduction

A1 = B1 = C1 Primary sections with standard winding C2 Row of embedded magnets

A2 Bolted-on standard secondary section

C3 Secondary section support made of

magnetically inactive material

A3 Secondary section support made of

magnetically active or inactive material

C5 Primary section with inverse winding

Magnet row starts with a north pole

Magnet row starts with a south pole

B3 Secondary section support made of

magnetically active material

Loading...

Loading...