Configuration

5.3 Examples

1FN3 linear motors

130 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

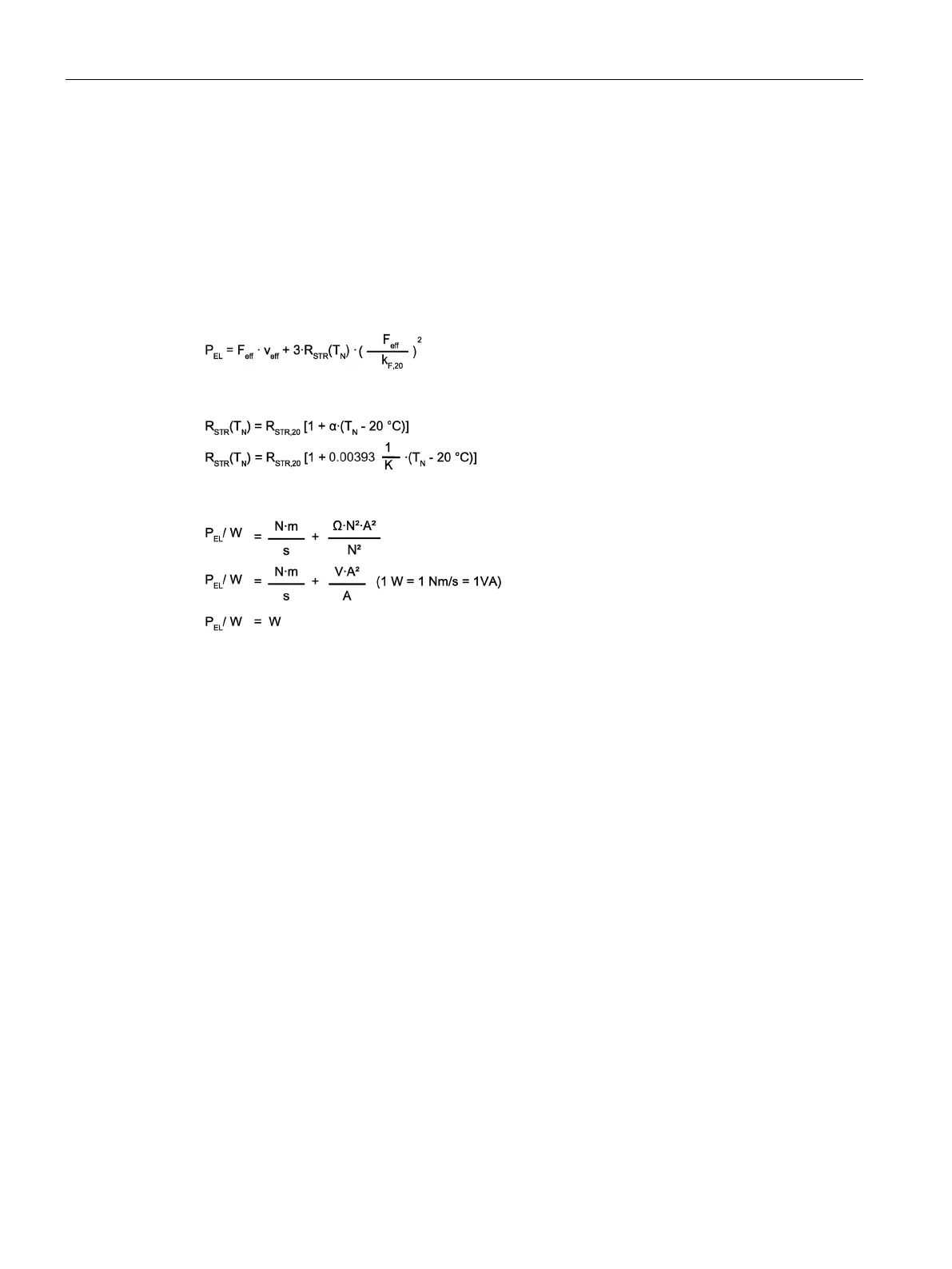

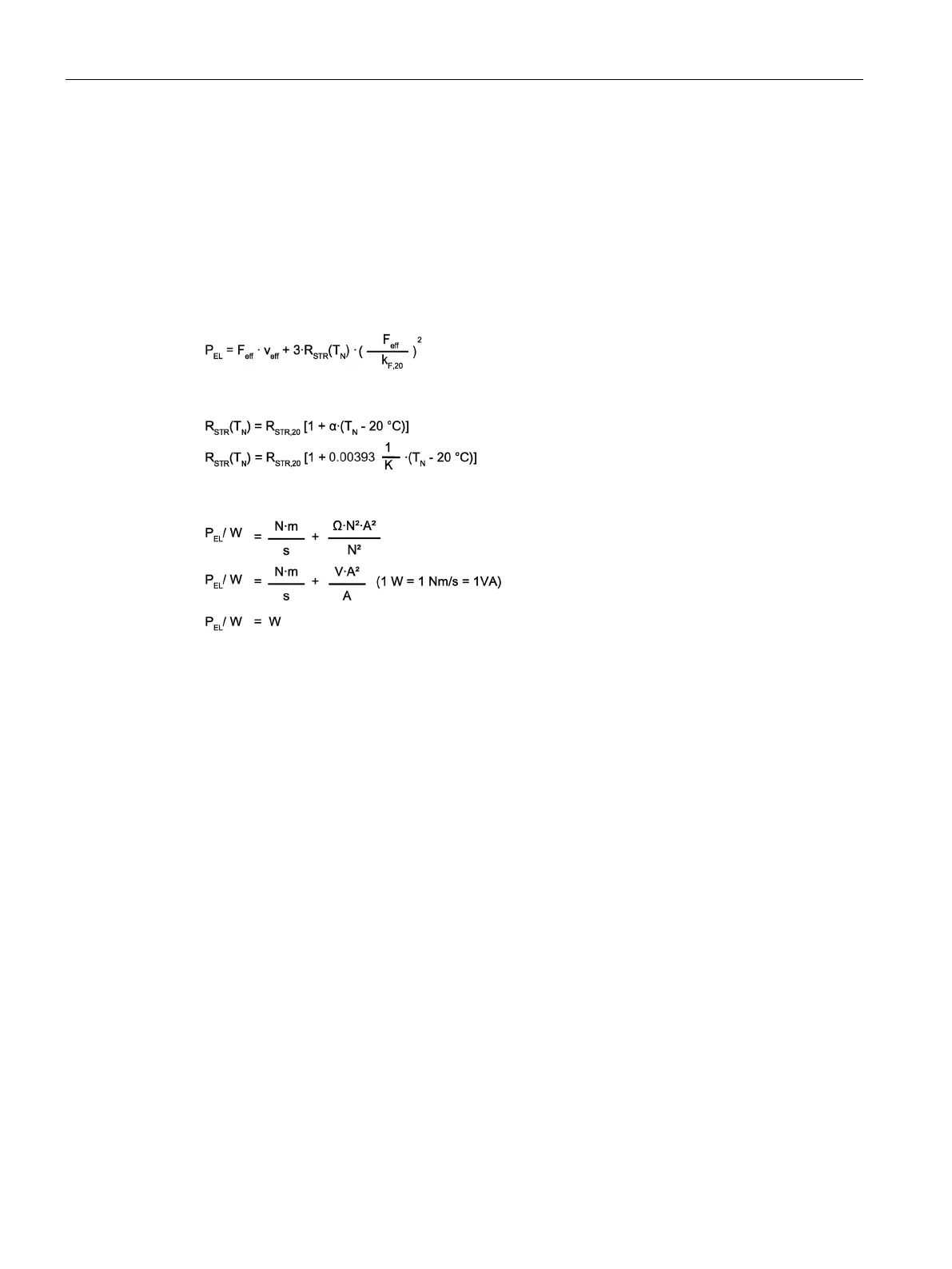

Calculating the infeed power

The electrical infeed power is obtained from the mechanical power P

MECH

and the power loss

of the motor P

V,Mot

. The rms values of the motor velocity and motor force resulting from the

duty cycle are used as basis for the calculation.

The rms infeed power is estimated as follows:

P

EL

= P

MECH

+ P

V,Mot

with

Controlling the unit:

To dimension the infeed (Active Infeed), in addition to the calculated value P

EL

, the power

loss of the Motor Module P

v,MoMo

and the Active Infeed P

V,AI

must also be added (see

Chapter "Calculation of the required infeed (Page 120)").

Gantry with transverse axis

Machining center with gantry axis

Frequently, an axis design in the form of a gantry is used for machining centers. The center

area of the slide of the gantry axis is required as machining space. This means that the

gantry is moved using two identical linear motors arranged at the sides.

The two motors are controlled from their own separate drive system – equipped with their

own position measuring system (gantry arrangement).

In the simplest scenario, the gantry has a symmetrical design, which means that each motor

must accelerate half the mass m

P

of the gantry.

In addition, an additional axis (transverse axis moving with the gantry) can be additionally

attached to the gantry, whose slides can be moved out of the center position. Depending on

the particular operating case, the mass distribution is no longer symmetrical. In this case, the

two motors of the gantry have to move different masses.

Loading...

Loading...