Movement Control Commands

3.5 Tool offset functions

04.07

3-75

© Siemens AG 2007 All rights reserved

SINUMERIK 802D sl/840D/840D sl/840Di/840Di sl/810D ISO Milling (PGM) -- 04.07 Edition

H code for designating the direction of offset

The direction of offset is determined by the sign of tool offset amount, specified by

an H code, and a G code.

Table 3-12 Sign of tool offset amount and direction of offset

Sign of tool offset amount (H code)

Positive Negative

G43 Offset in the positive direc-

tion

Offset in the negative direc-

tion

G44 Offset in the negative direc-

tion

Offset in the positive direc-

tion

Example of programming

H10 Offset amount --3.0.............

H11 Offset amount 4.0.............

N101 G92 Z0; 0.000

N102 G90 G00 X1.0 Y2.0; 0.000

N103 G43 Z-20. H10; --23.000

N104 G0l Z-30. Fl000; --33.000

N105 G00 Z0H00; 0.000

··

··

··

N201 G00 X-2.0 Y-2.0;

N202 G44 Z-30 Hl1; --34.000

N203 G01 Z-40 F1000; --44.000

N204 G00 Z0 H00; 0.000

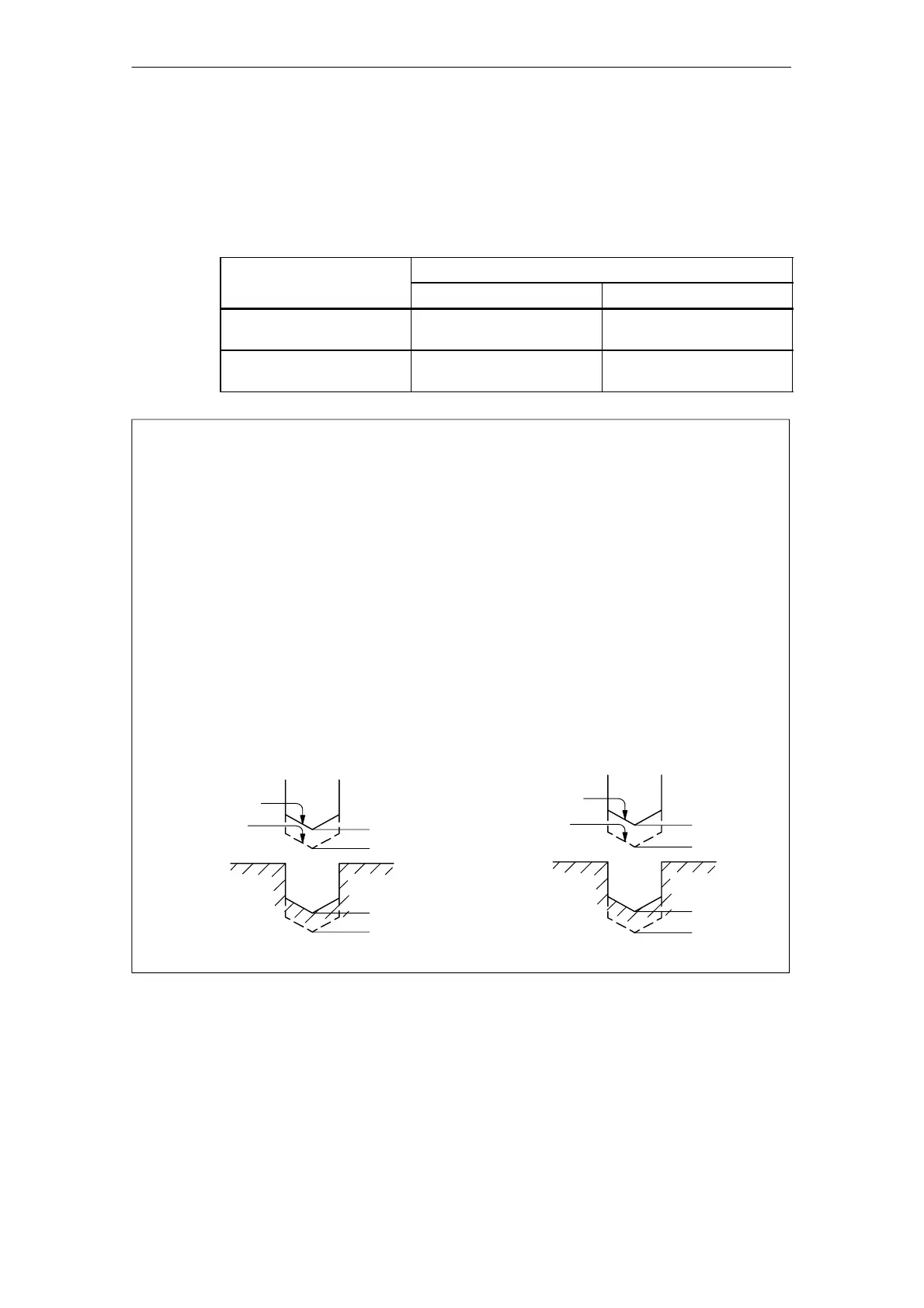

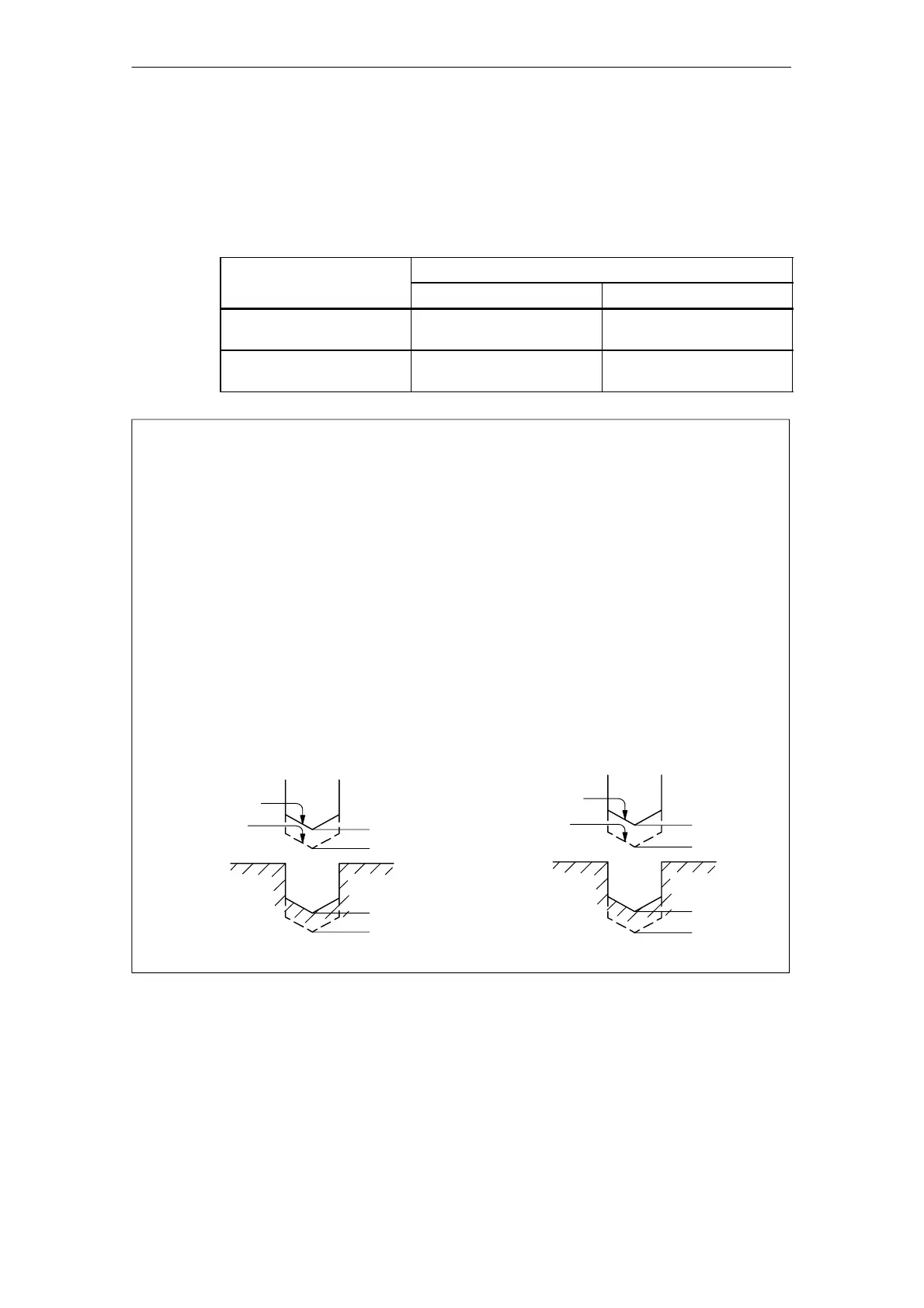

Programmed position

Actual tool position

--20.000

--23.000

--30.000

--33.000

--30.000

--34.000

--40.000

--44.000

Position data display

including offset amount

(Z-axis only)

Programmed position

Actual tool position

Fig. 3-17 Tool position offset function

S Related Machine data:

$MC_TOOL_CORR_MOVE_MODE defines whether the compensation is

applied in the block containing the selection or the next time the axis is

programmed.

$MC_CUTTING_EDGE_DEFAULT = 0 defines that no tool length compensa-

Loading...

Loading...