Enhanced Level Commands

4.1 Program support functions (1)

04.07

4-93

© Siemens AG 2007 All rights reserved

SINUMERIK 802D sl/840D/840D sl/840Di/840Di sl/810D ISO Milling (PGM) -- 04.07 Edition

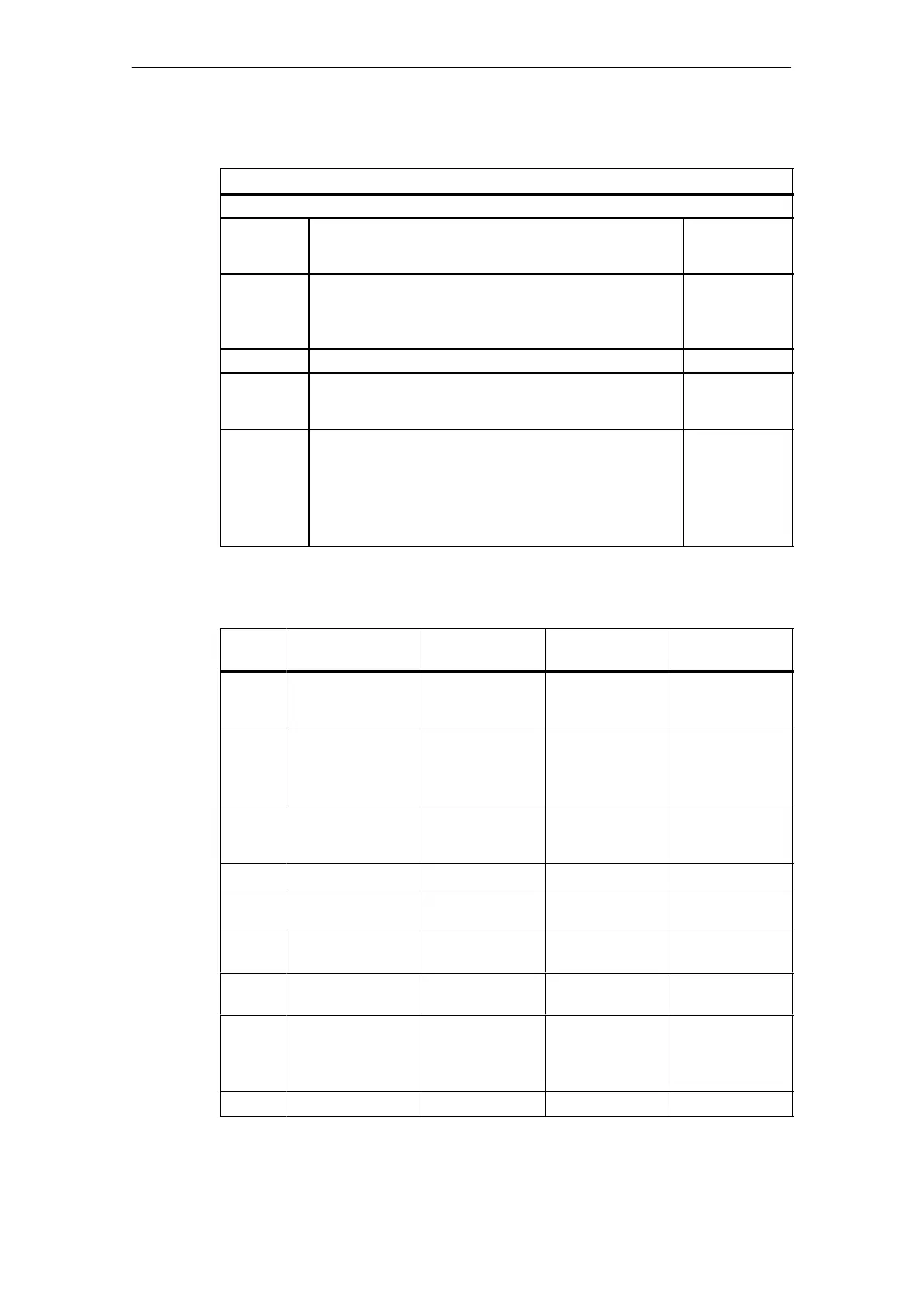

Table 4-2 GUD7 for cycle setting data (ISO dialect setting data), continued

Integer values

Integer values

_ZSFI[0] 0=Drilling axis is the axis perpendicular to the selected

plane (default)

1=Drilling axis always ”Z”

381M, 383M,

384M, 387M

_ZSFI[1] 0= Rigid tapping

1= Tapping with compensating chuck

2= Deep hole tapping with chip--breaking

3= Deep hole tapping with swarf removal

384M, 387M

_ZSFI[2] Retraction speed factor (1--200%) for tapping (G74/G84) 384M

_ZSFI[3] Polar coordinates

0=OFF

1=ON

381M, 383M,

384M, 387M

_ZSFI[5] Retraction direction (G76/G87)

G17 G18 G19

_ZSFI[5] = 1 +X +Z +Y

_ Z S F I [ 5 ] = 0 o r 2 -- X -- Z -- Y

_ZSFI[5] = 3 +Y +X +Z

_ZSFI[5] = 4 --Y --X --Z

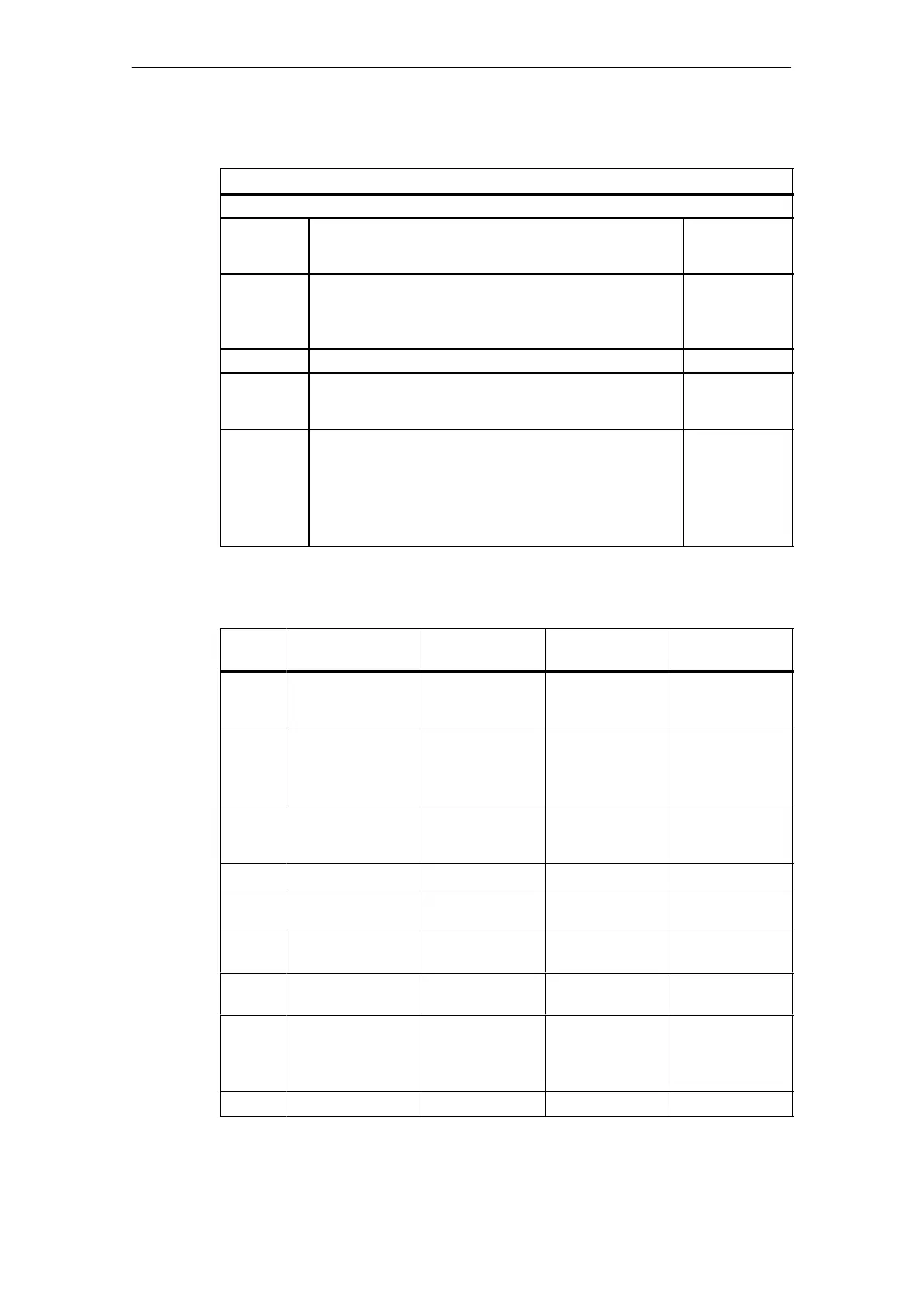

For calling normal hole-machining canned cycles, the following G c odes are used.

Table 4-3 GUD7 for cycle setting data (ISO dialect setting data)

G code

Drilling

(--Z direction)

Processing at

hole bottom

Retraction

(+Z direction)

Applications

G73

Intermittent feed

(dwell at each peck

feed possible)

— Rapid traverse

High-speed deep

hole drilling

G74 Cutting feed

Spindle stop→

Spindle rotation in

the reverse direc-

tion after dwell

Cutting feed →

Dwell → Spindle

reverse rotation

Reverse (left--

hand) tapping

G76 Cutting feed

Spindle indexing

after dwell →

Shift

Rapid traverse →

Shift, Spindle

start

Boring

G80 — — — Cancel

G81 Cutting feed — Rapid traverse

Drilling,

spot drilling

G82 Cutting feed Dwell Rapid traverse

Drilling,

counter boring

G83 Intermittent feed — Rapid traverse

Deep hole drilling

(peck drilling)

G84 Cutting feed

Spindle stop→

Spindle start in

the reverse direc-

tion after dwell

Cutting feed →

Dwell → Spindle

reverse rotation

Tapping

G85 Cutting feed — Cutting feed Boring

Loading...

Loading...