Detailed Description

2.3 Tool cutting edge

Tool Compensation (W1)

2-38 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

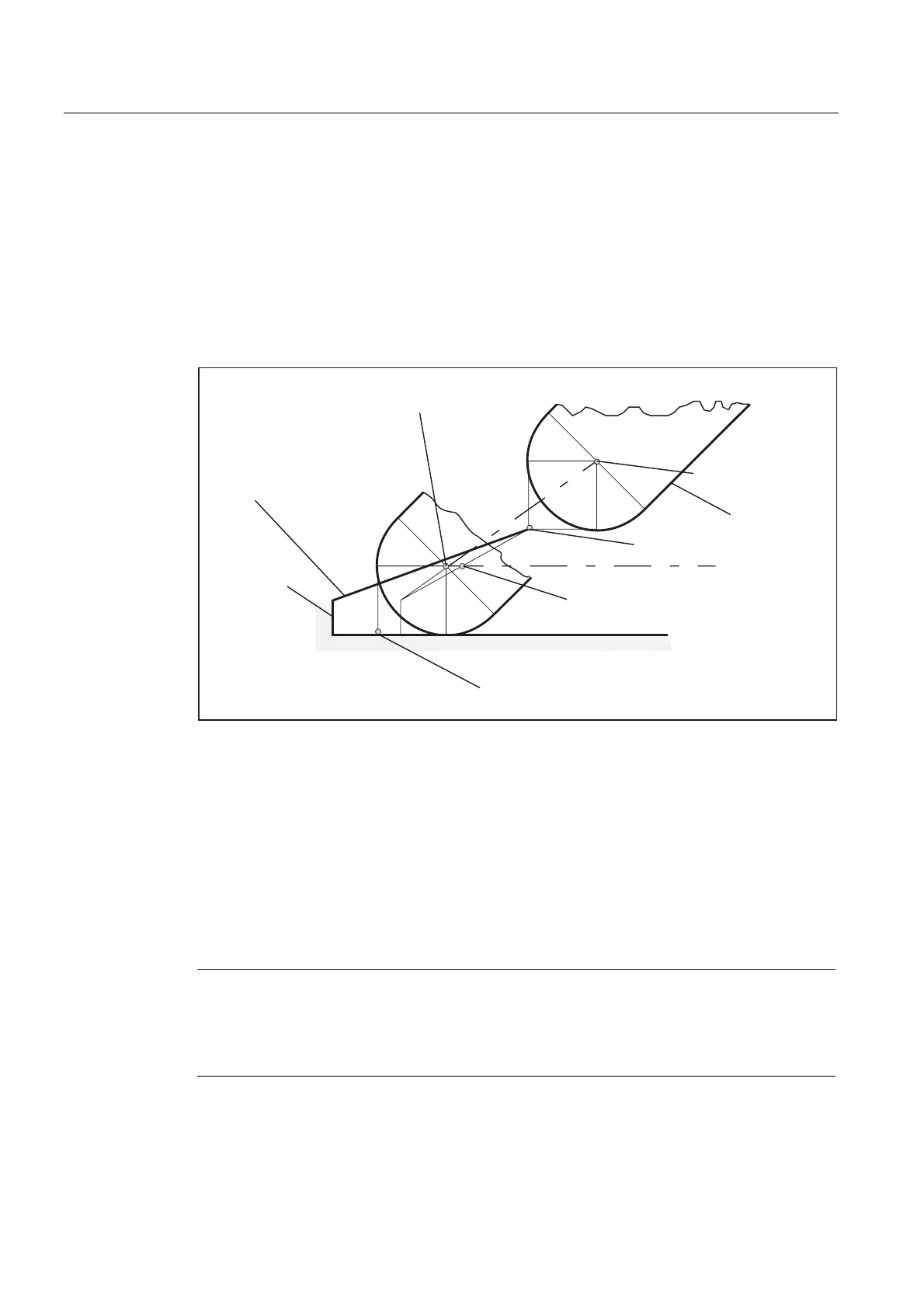

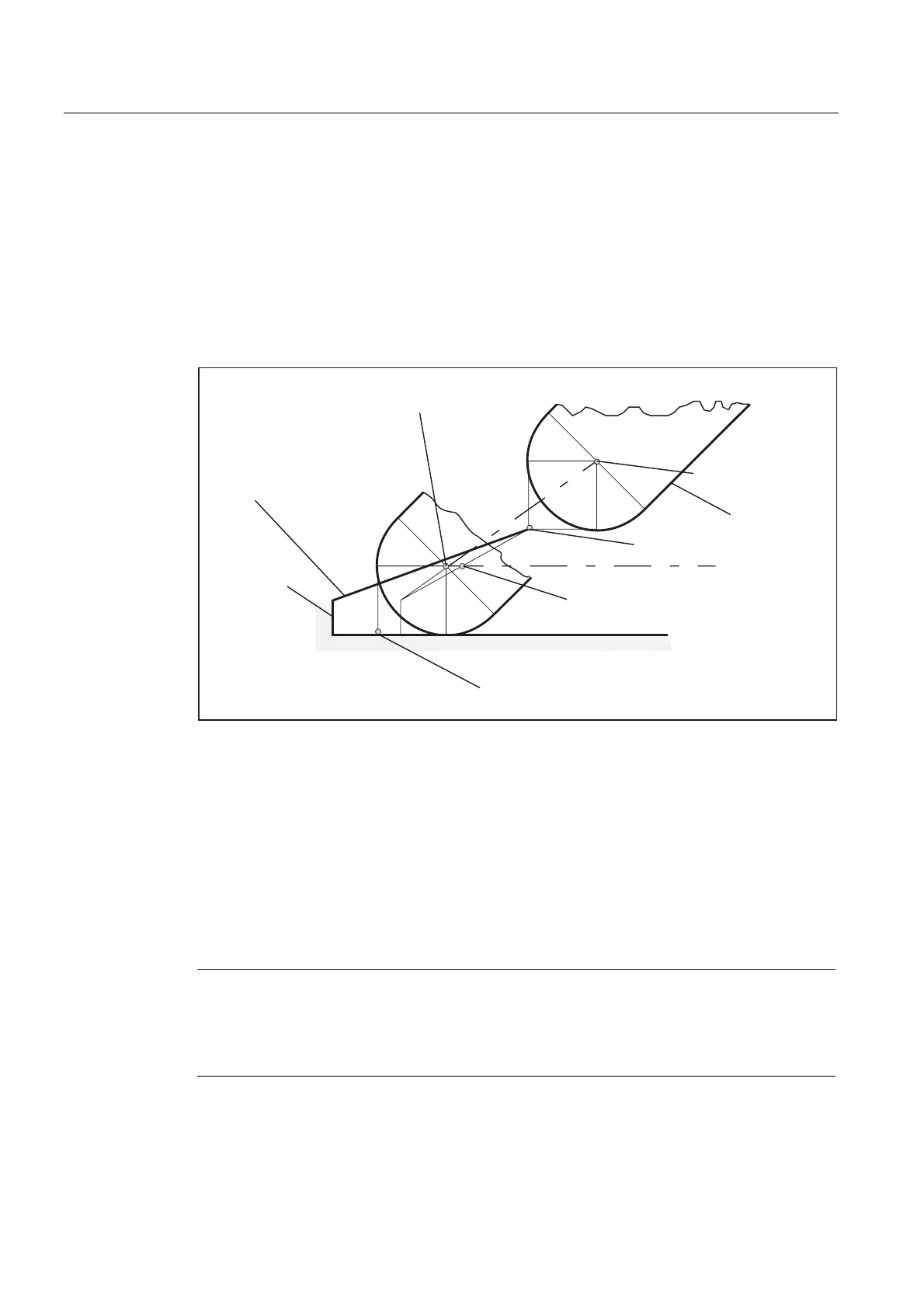

2. The straight line between the tool edge center points at the block start and block end is

used to calculate intersection points with the approach and retraction block. The

difference between the tool edge reference point and the tool edge center point is

superimposed on this movement.

For approach and/or retraction with KONT, the movement is superimposed in the linear

subblock of the approach or retraction movement. Therefore, the geometric conditions for

tools with or without relevant tool point direction are identical. Deviations from previous

behavior occur only in relatively rare cases where the approach or retraction block does

not intersect with an adjacent motion block:

/DVWSRVLWLRQRIFXWWLQJHGJHFHQWHUSRLQW

RQWKHFRQWRXU6:DQGKLJKHU

3URJUDPPHGUHWUDFWLRQEORFN

%ORFNZLWKRXW

LQWHUVHFWLRQ

ZLWKSUHFHGLQJEORFN

7RROHGJHUHIHUHQFHSRLQW

/DVWSRVLWLRQRIFXWWLQJHGJHFHQWHUSRLQW

RQWKHFRQWRXUXSWR6:[

&HQWHUSDWK

7RROHGJHUHIHUHQFHSRLQW

7RROHQGSRVLWLRQ

&XWWLQJHGJHFHQWHUSRLQW

Fig. 2-13 Retraction behavior for tool with relevant tool point direction

1. In circle blocks and in motion blocks containing rational polynomials with a denominator

degree > 4, it is not permitted to change a tool with active tool radius compensation in

cases where the distance between the tool edge center point and the tool edge reference

point changes. With other types of interpolation, a change is permitted even when a

transformation (e.g., Transmit) is active, in contrast to previous versions.

2. For tool radius compensation with variable tool orientation, the transformation from the

tool edge reference point to the tool edge center point can no longer be performed by

means of a simple zero compensation. Tools with a relevant tool point direction are

therefore not permitted for 3D peripheral milling (an alarm is output).

Note

The subject is irrelevant with respect to face milling as only defined tool types without

relevant tool point direction are permitted for this operation anyway. (A tool with a type,

which has not been explicitly approved, is treated as a ball end mill with the specified radius.

A tool point direction parameter is ignored.)

Loading...

Loading...