Detailed Description

2.2 Encoder monitoring

Axis Monitoring, Protection Zones (A3)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-19

The type of zero mark monitoring depends on the type of encoder used:

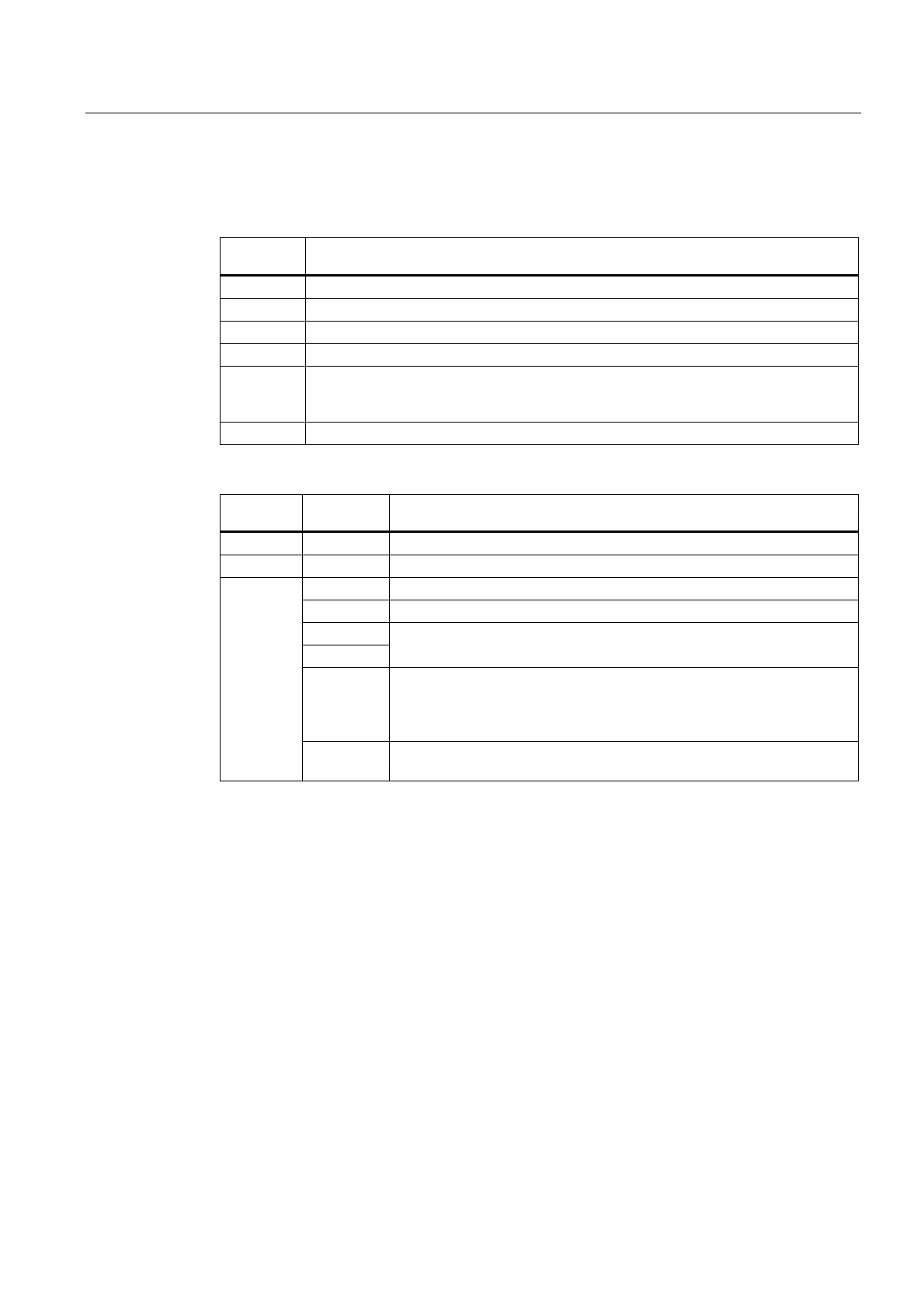

MD30240 $MA_ENC_TYPE = <

encoder type

>

Encoder

type

Meaning

0 Simulation

1 Raw signal generators (voltage, current, EXE etc.) -> High resolution

2 Rectangular signal encoder (standard, no. of PPRs quadrupled)

3 Encoder for stepper motor

4 Absolute value encoder

- SIMODRIVE 611D: absolute encoder with EnDat interface only

- PROFIBUS drives: No restriction

5 Encoder with SSI interface

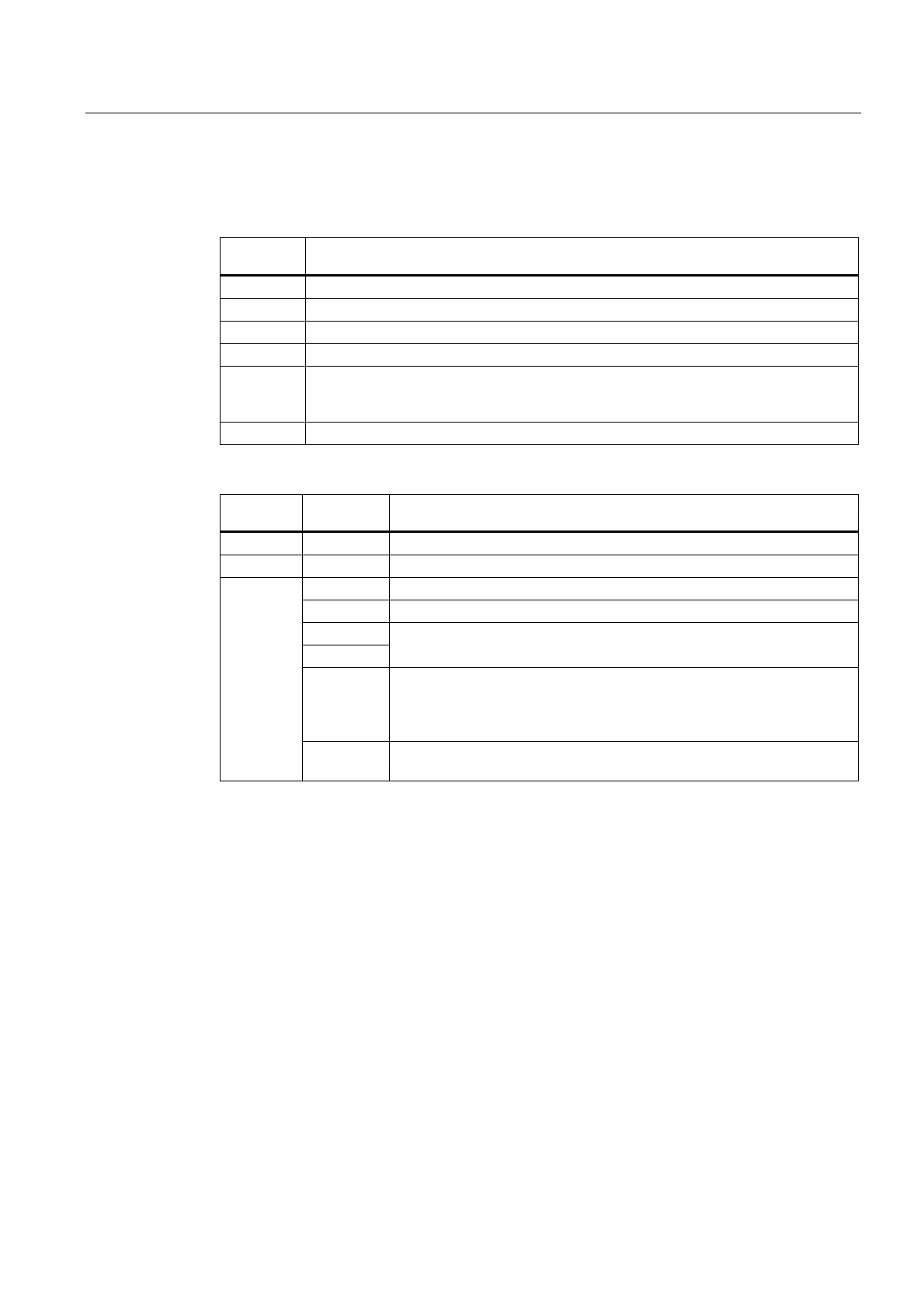

The following table shows the corresponding context:

MD36310

Encoder

type

Function

0 - No zero mark monitoring.

100 - No zero mark monitoring and suppress encoder alarms.

0 No zero mark monitoring.

3 No zero mark monitoring.

1

2

Number of detected changes on which an alarm is to be output. Every

time the encoder is switched on, counting starts at "0".

4 Permissible deviation between the absolute and incremental encoder

track in 1/2 rough lines. It is generally sufficient to enter a 1/2 rough line. If

this is exceeded, alarm 20510 is triggered. (See below: Boundary

conditions)

> 0

5 No zero mark monitoring.

Power-ON-Alarm 25000 instead of Reset-Alarm 20510.

Effect

Active measuring system

The following occurs when the zero mark monitoring is initiated:

• Alarm: "25020 Axis <

Axis identifier

> Zero mark monitoring of active encoder"

• The affected axis is stopped via the configured braking ramp in follow-up mode:

MD36610 $MA_AX_EMERGENCY_STOP_TIME

(Time for braking ramp when an error occurs)

• If the axis/spindle is involved in interpolation with other axes/spindles, these are brought

to a standstill with rapid stop (set velocity = 0).

Loading...

Loading...