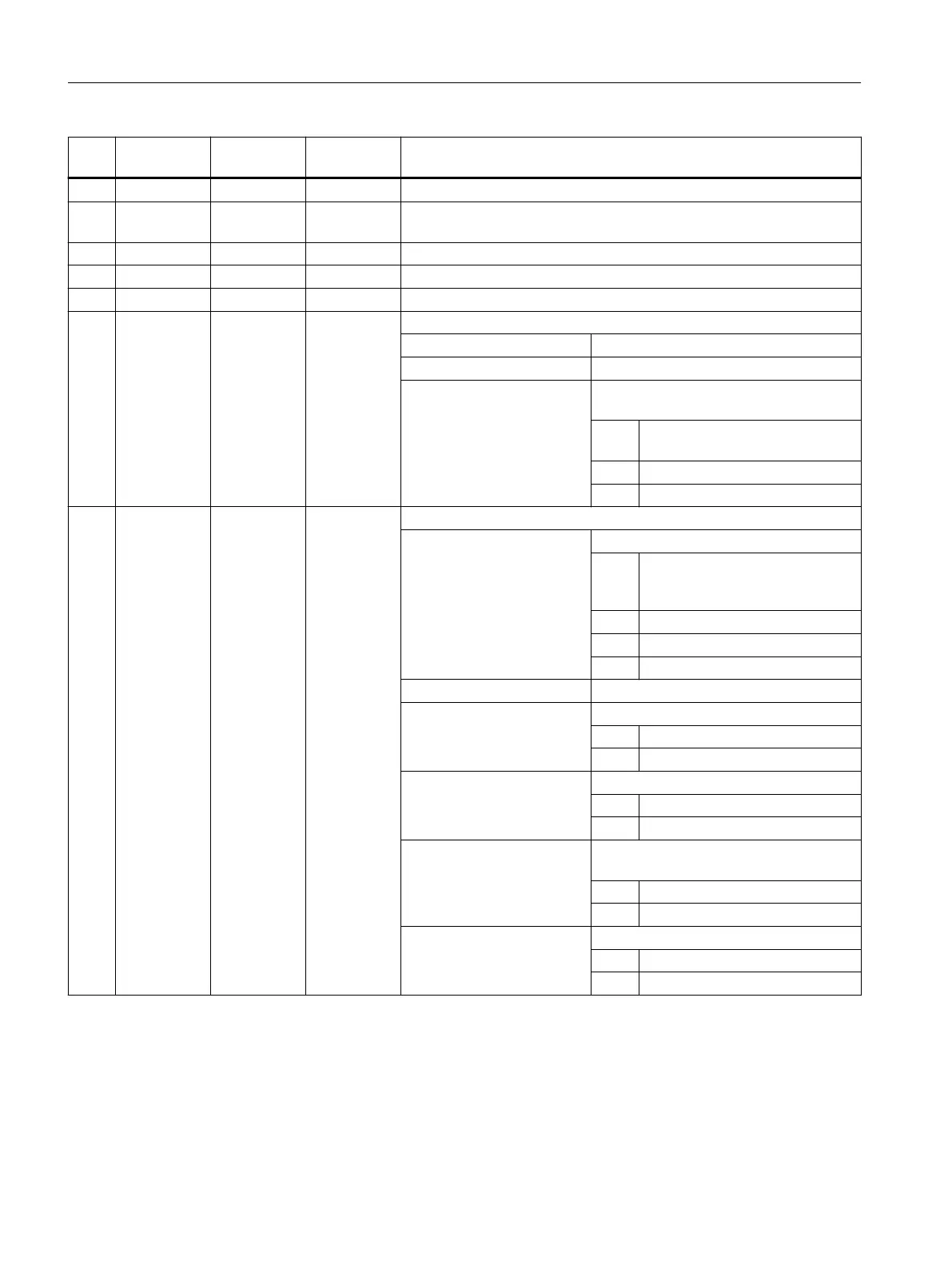

No. Parameter

mask

Parameter

internal

Data type Meaning

19 FS <_FS> REAL Chamfer width (inc) for chamfering

20 ZFS <_ZFS> REAL Insertion depth of tool tip when chamfering (see <_AMODE> HUN‐

DREDS)

21 TR <_TR> STRING[32] Reference tool name when machining residual material

22 DR <_DR> INT Reference tool D number when machining residual material

23 <_UMODE> INT Reserved

24 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

HUNDREDS: Select machining/only calculation of start

point

0 = Normal machining (no compatibil‐

ity mode needed)

1 = Normal machining

2 = Reserved

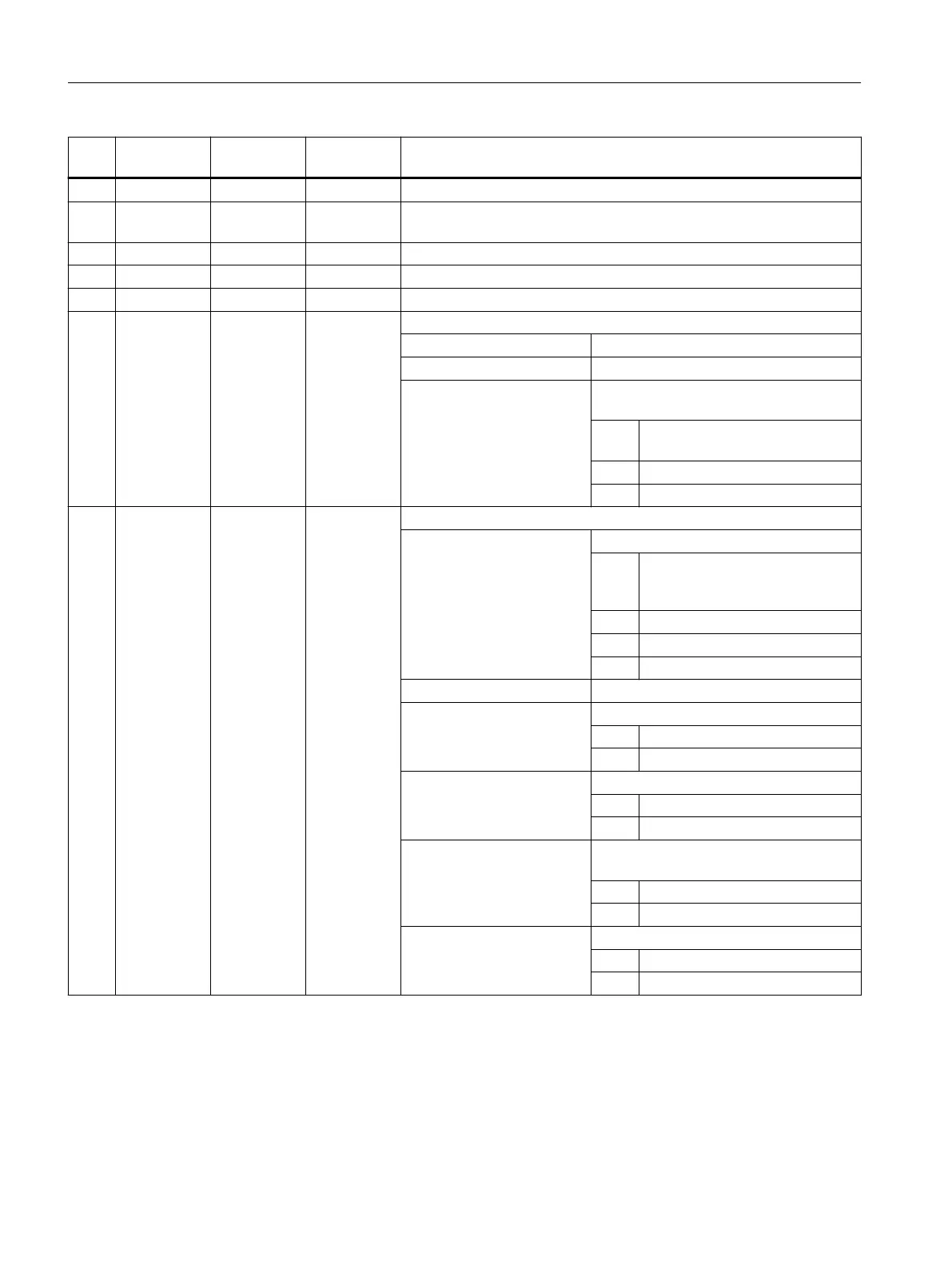

25 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

TENS: Reserved

HUNDREDS: Technology mode

1 = Pocket

2 = Spigot

THOUSANDS: Machine residual material

0 = No

1 = Yes

TEN THOUSANDS: Technology scaling in cycle screen forms

(Page 1153)

0 = Input: Complete

1 = Input: Simple

HUNDRED THOUSANDS: Automatic program name

0 = No

1 = Yes

Work preparation

3.25 Programming cycles externally

NC programming

1048 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...