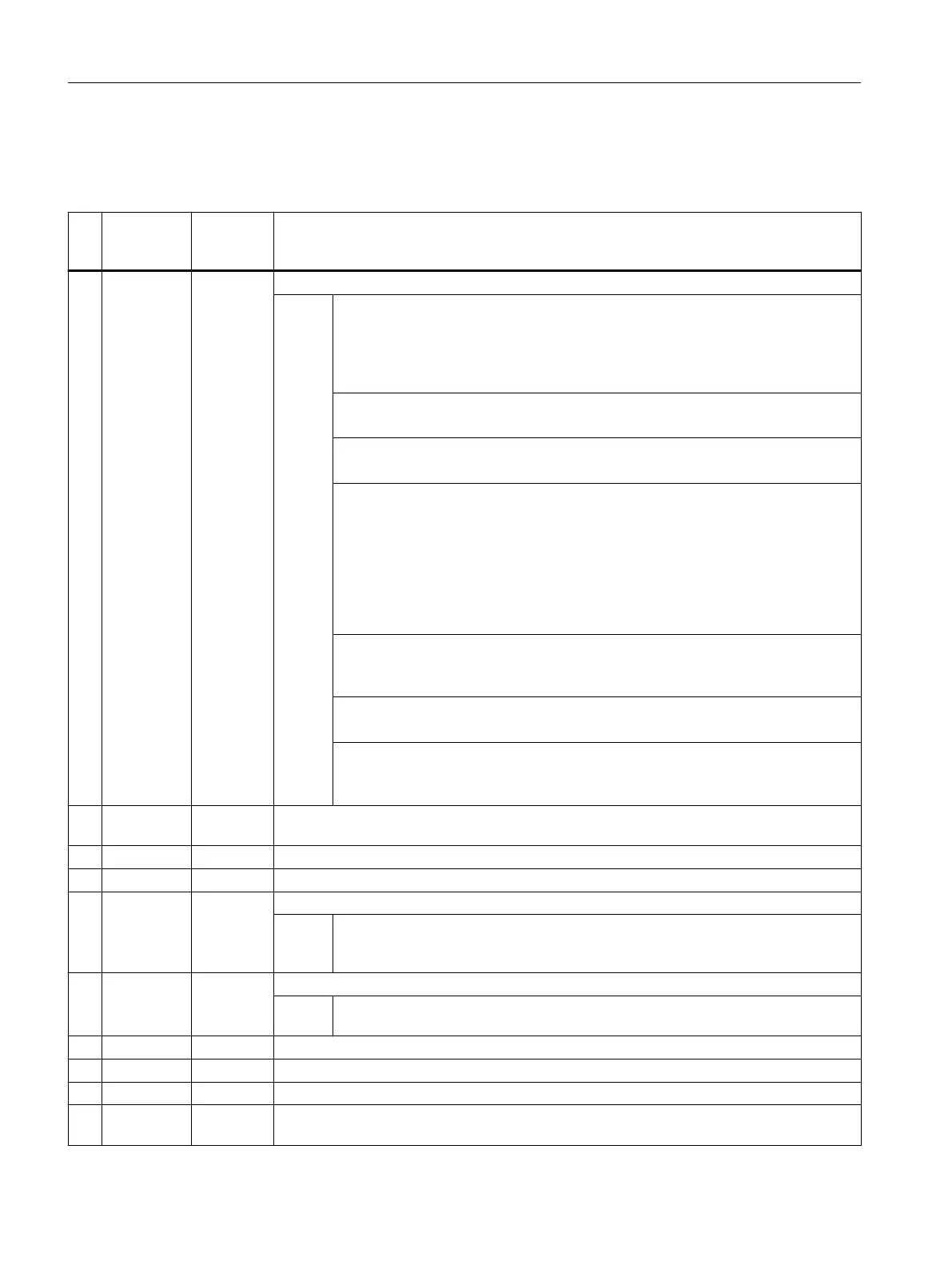

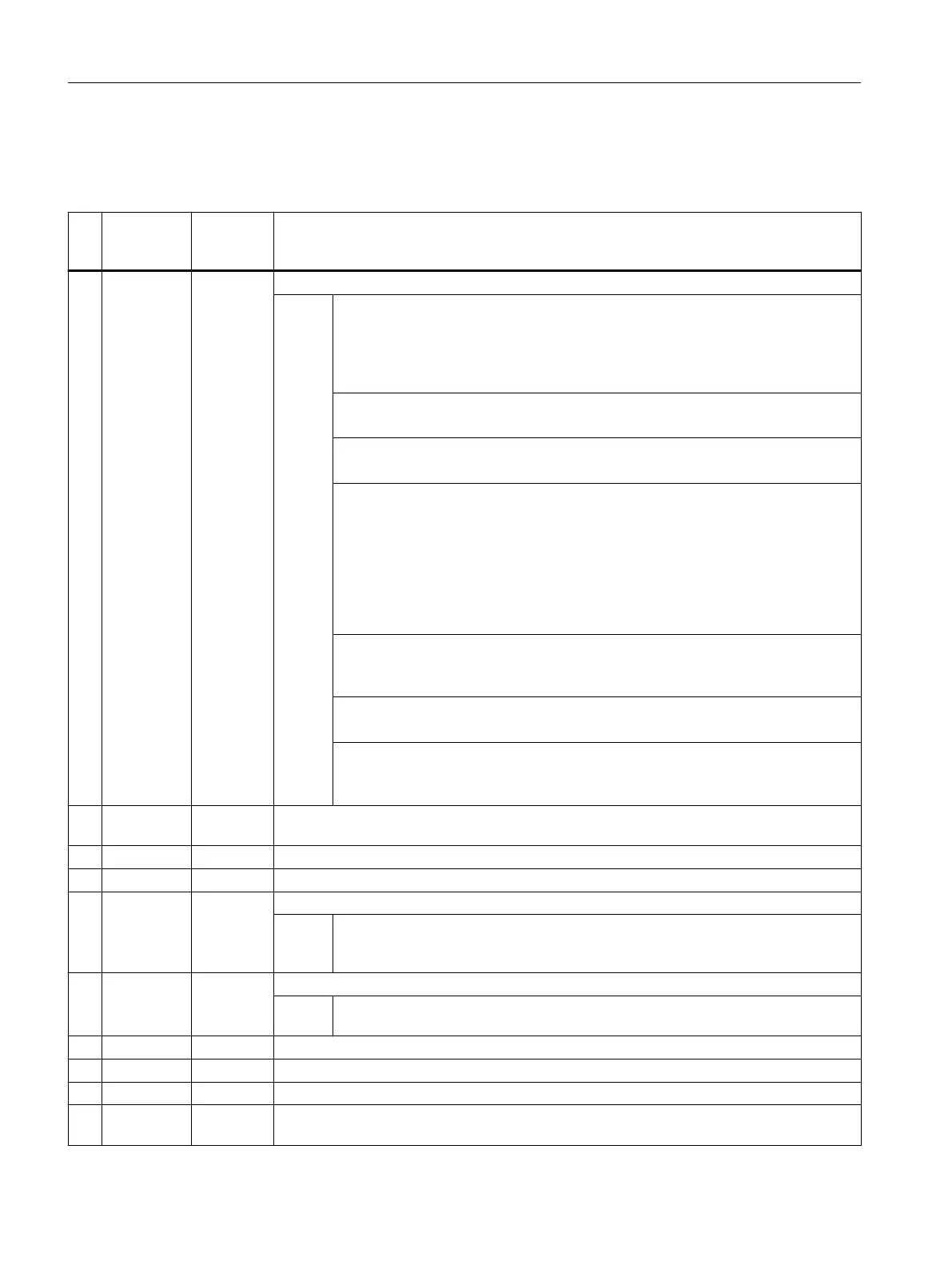

Table 3-8 CYCLE973 call parameters

1)

No. Screen

form param‐

eter

Cycle pa‐

rameter

Meaning

1 S_MVAR Measuring variant (default=0012103)

Val‐

ues:

UNITS: Calibration on a surface, edge or in a groove

0 = Length on surface/edge (in the WCS) with known setpoint

1 = Radius on surface (in the WCS) with known setpoint

2 = Length in groove (in the WCS), see S_CALNUM

3 = Radius in groove (in the WCS), see S_CALNUM

TENS: Reserved

0 = 0

HUNDREDS: Reserved

0 = 0

THOUSANDS: Selection of measuring axis and measuring direction for calibra‐

tion

2)

0 = No specification (for surface calibration on the groove base, no selection of the

measuring axis and measuring direction)

4)

1 = Specify selection of measuring axis and measuring direction, see S_MA, S_MD

(one measuring direction in a measuring axis)

2 = Specify selection of measuring axis, see S_MA (two measuring directions in a

measuring axis)

TEN THOUSANDS: Determination of the positional deviation (probe skew)

2), 3)

0 = Determine positional deviation

1 = Do not determine positional deviation

HUNDRED THOUSANDS: Reserved

0 = 0

ONE MILLION:adapt tool length

7)

0 = Do not adapt tool length (only trigger points)

1 = Adapt tool length

2 Icon+

number

S_PRNUM Number of the field of the probe parameters (not probe number)

(default=1)

3 S_CALNUM Number of the calibration groove for calibration on a groove (default=1)

5)

4 S_SETV Setpoint for calibration on a surface

5 X0 S_MA Measuring axis (number of the axis)

6)

(default=1)

Val‐

ues:

1 = 1st axis of the plane (for G18 Z)

2 = 2nd axis of the plane (for G18 X)

3 = 3rd axis of the plane (for G18 Y)

6)

6 +- S_MD Measuring direction (default=1)

Val‐

ues:

0 = Positive measuring direction

1 = Negative measuring direction

7 DFA S_FA Measurement path

8 TSA S_TSA Safe area

9 VMS S_VMS Variable measuring velocity for calibration

2)

10 Measure‐

ments

S_NMSP Number of measurements at the same location

2)

(default=1)

Work preparation

3.25 Programming cycles externally

NC programming

1156 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...