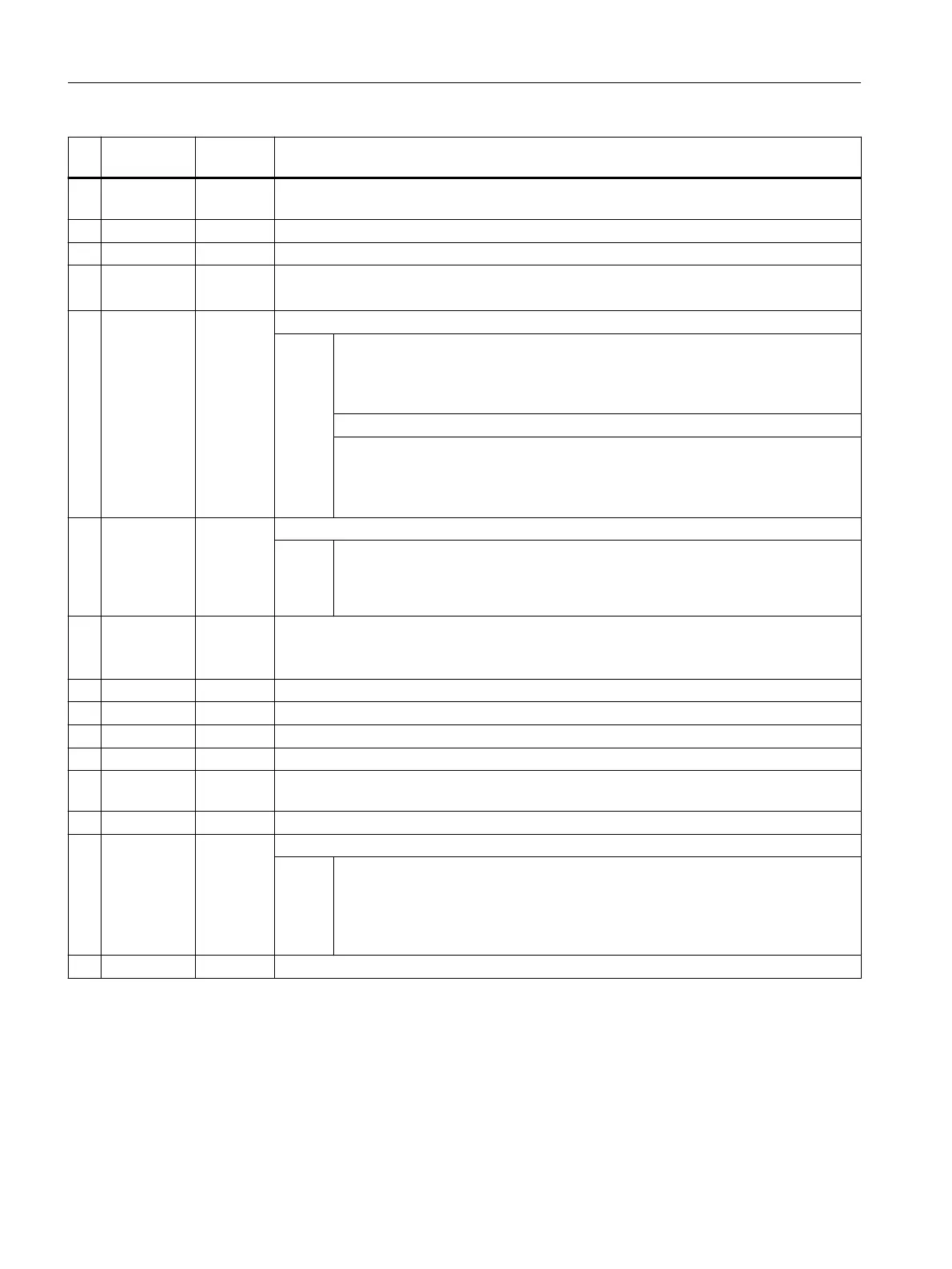

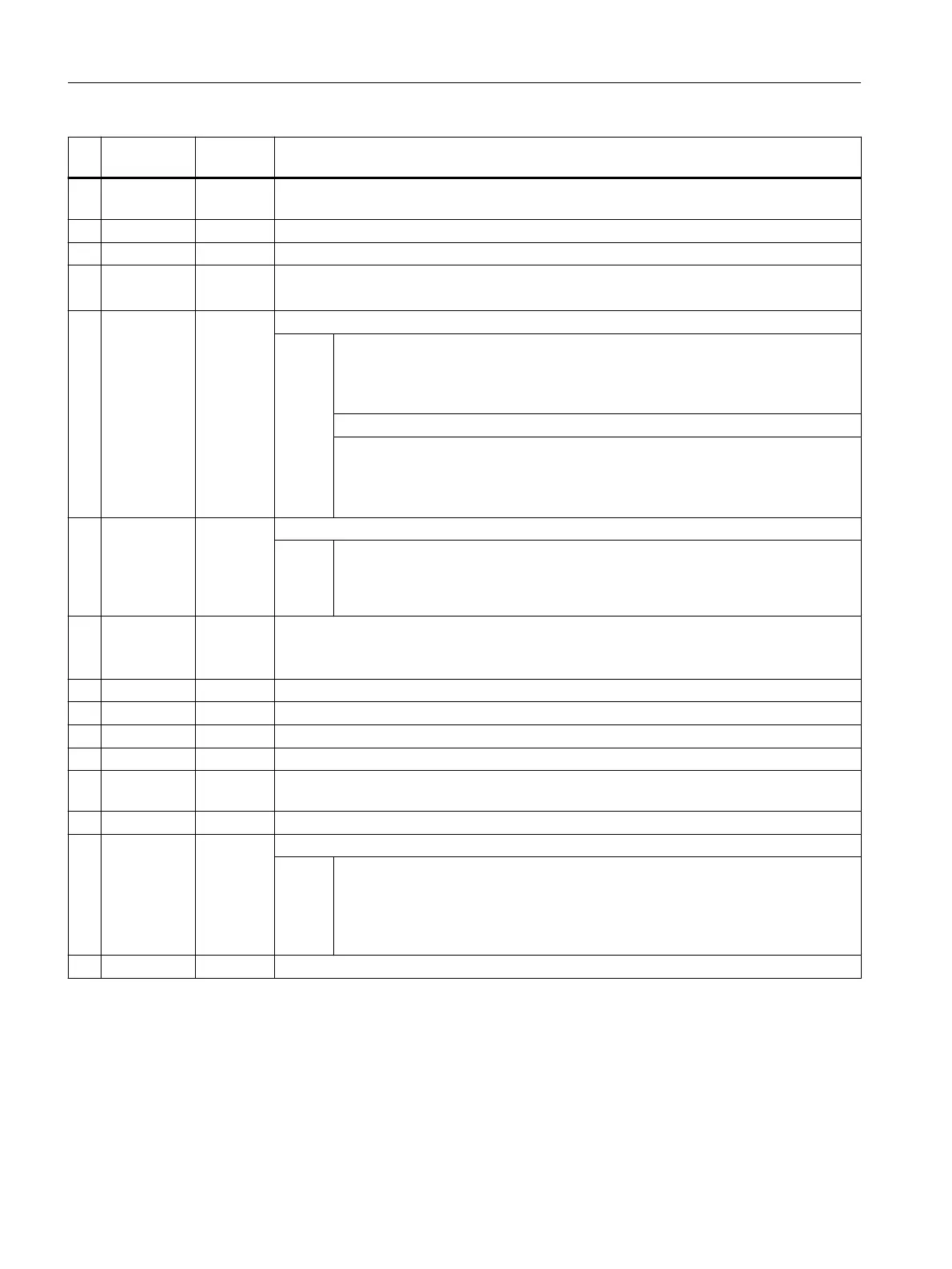

No

.

Screen form

parameter

Cycle pa‐

rameter

Meaning

6 α S_STA1 Angle setpoint for "Align edge" or for "Align plane" around the 1st axis of the plane (for G17

X)

9)

7 β S_INCA Angle setpoint for "Align plane" around the 2nd axis of the plane (for G17 Y)

9)

8 DFA S_FA Measurement path

9 TSA S_TSA Safe area

Monitoring of the angle difference to the angle setpoint [degrees]

6)

10 X / Y / Z S_MA Measuring axis, offset axis

7)

(default=201)

Val‐

ues:

UNITS: Number of the measuring axis

1 = 1st axis of the plane (for G17 X)

2 = 2nd axis of the plane (for G17 Y)

3 = 3rd axis of the plane (for G17 Z)

TENS: Reserved

HUNDREDS: Number of the offset axis

1 = 1st axis of the plane (for G17 X)

2 = 2nd axis of the plane (for G17 Y)

3 = 3rd axis of the plane (for G17 Z)

11 +- S_MD Measuring direction of the measuring axis

8)

Val‐

ues:

0 = Measuring direction is determined from the setpoint and the actual position of

the measuring axis (compatibility)

1 = Positive measuring direction

2 = Negative measuring direction

12 L2 S_ID For measuring variant "Align edge":

Distance (incremental) between the measuring points P1 and P2 in the offset axis (value >0)

For measuring variant "Align plane", the parameters listed below apply.

13 L2 S_SETV0 Distance between the measuring points P1 and P2 in the 1st axis of the plane

10)

14 S_SETV1 Distance between the measuring points P1 and P2 in the 2nd axis of the plane

11), 12)

15 L3x S_SETV2 Distance between the measuring points P1 and P3 in the 1st axis of the plane

11)

16 L3y S_SETV3 Distance between the measuring points P1 and P3 in the 2nd axis of the plane

10)

17 Measure‐

ments

S_NMSP Number of measurements at the same location

2)

(default=1)

18 S_EVNUM Date set, empirical value memory

2), 13)

19 _DMODE Display mode

Val‐

ues:

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane active before the cycle call remains active

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

20 _AMODE Reserved (alternative mode)

1)

All default values = 0 or marked as default=x

2)

Display depends on the general SD54760 $SNS_MEA_FUNCTION_MASK_PIECE

3)

WO "fine" only if correction target is rotary axis and MD 52207 $MCS_AXIS_USAGE_ATTRIB[n] Bit6=1.

If WO has not been set up in MDs, correction is according to WO "coarse".

4)

Example for offset in coordinate rotation: S_MA=102 Measuring axis Y, offset axis X results in coordinate rotation around

Z (for G17)

5)

Value only relevant for protection zone "Yes" (S_MVAR THOUSANDS position = 1)

Work preparation

3.25 Programming cycles externally

NC programming

1170 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...