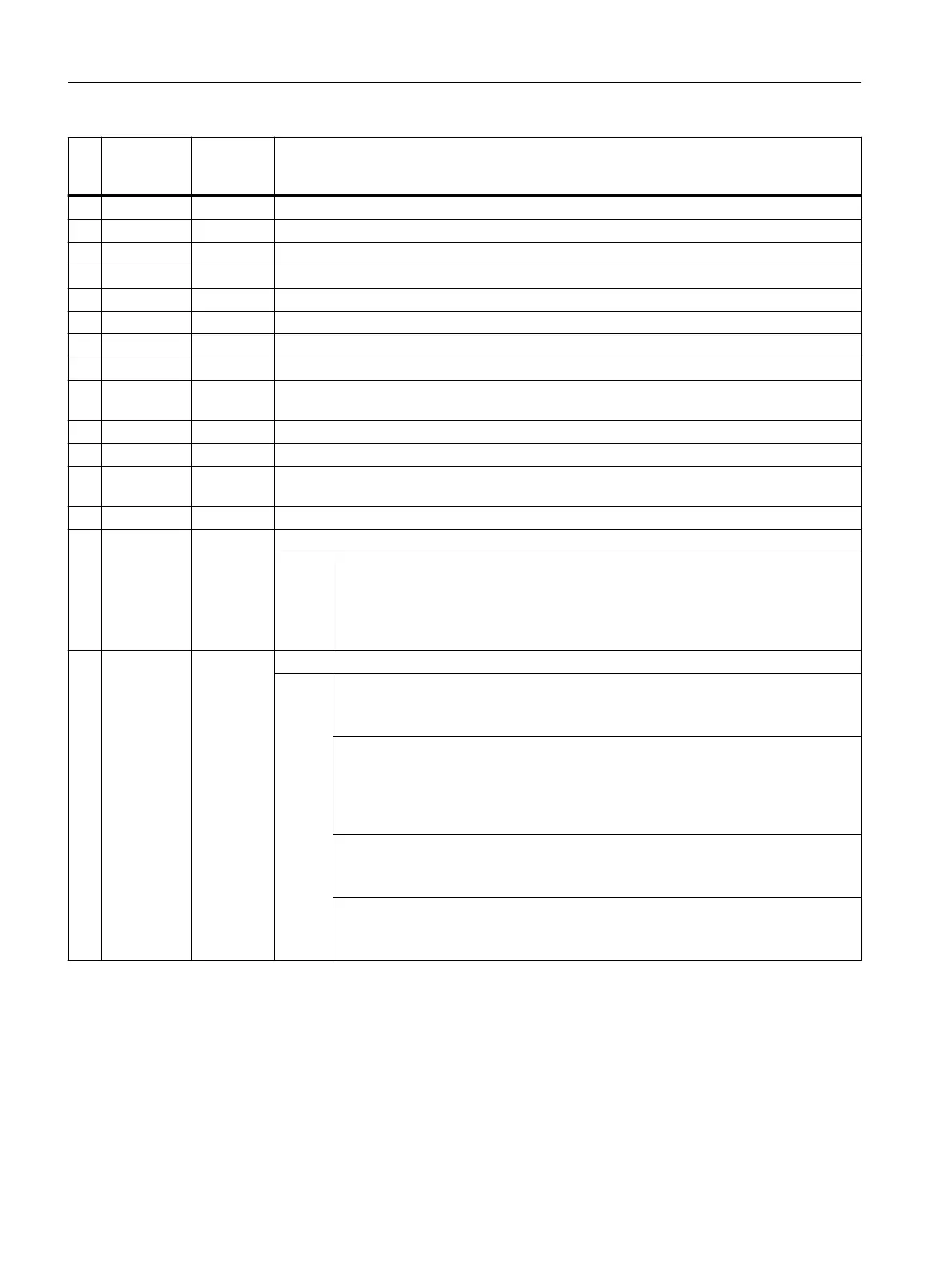

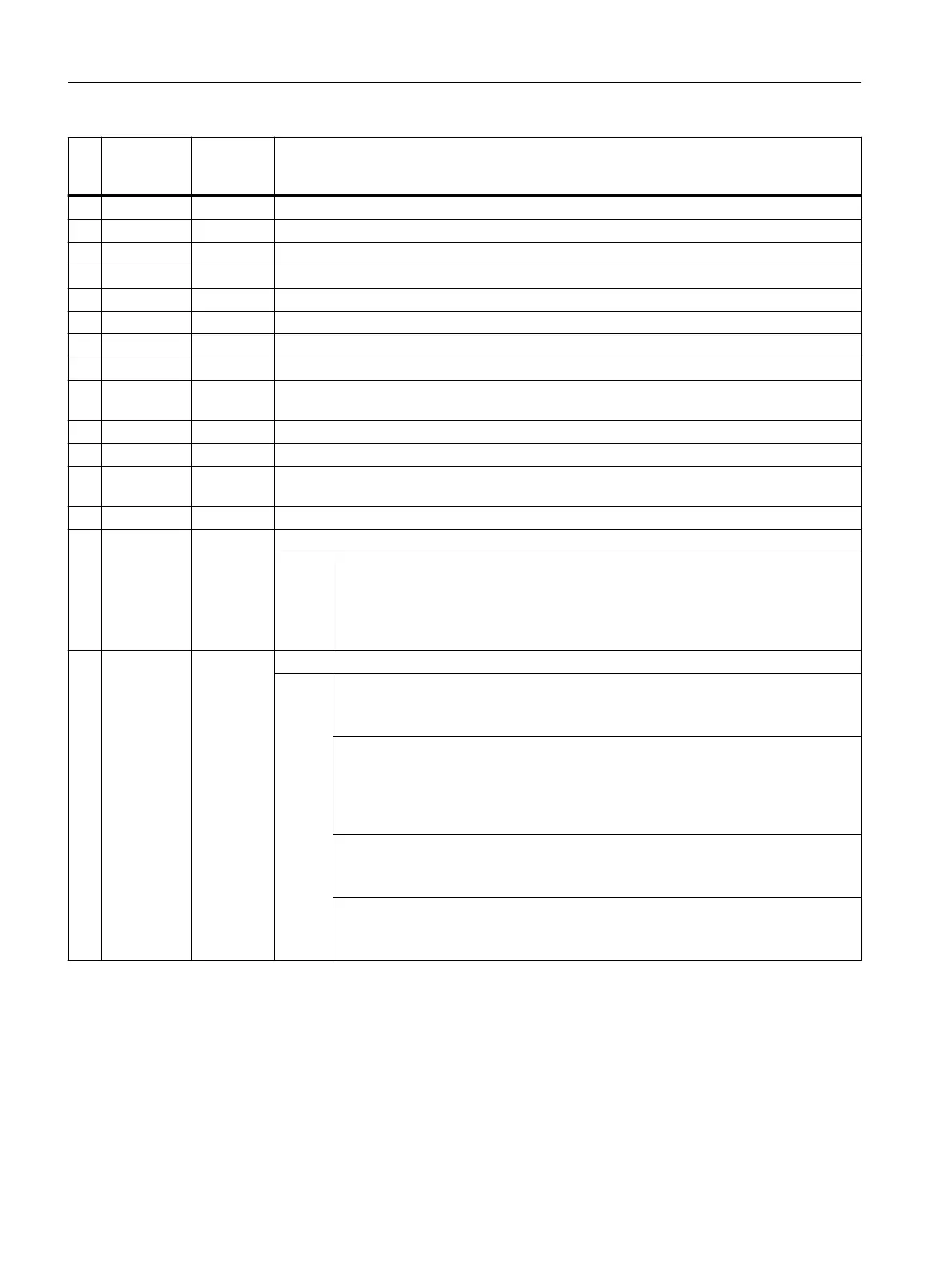

No

.

Screen

form param‐

eter

Cycle pa‐

rameter

Meaning

4 S_SETV Diameter of the calibration ball

5 alpha 0 S_STA1 Starting angle for measurement at an angle

6 alpha 0 S_SETV0 Position value of rotary axis 1 (if rotary axis is manual or semi-automatic)

7 alpha 1 S_SETV1 Position value of rotary axis 2 (if rotary axis is manual or semi-automatic)

6)

8 XN S_SETV2 Position value for normalizing rotary axis 1

9 XN S_SETV3 Position value for normalizing of rotary axis 2

6)

10 Delta S_SETV4 Tolerance value of the offset vectors I1 to I4

11 Delta S_SETV5 Tolerance value of rotary axis vectors V1 and V2

12 TVL S_TNVL Limit value of angular segment of the rotary axis (value range 1 to 60 degrees)

(default=20)

7)

13 DFA S_FA Measurement path

14 TSA S_TSA Safe area

15 Measure‐

ments

S_NMSP Number of measurements at the same location

2)

(default=1)

16 S_MCBIT Reserved

17 _DMODE Display mode

Val‐

ues:

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane active before the cycle call remains active

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

18 _AMODE Alternative mode

Val‐

ues:

UNITS: Tolerance check yes/no

0 = No

1 = Yes: Evaluation of the tolerance values of the vectors S_SETV4, S_SETV5

TENS: Acknowledgment by the operator when entering the calculated vectors in

the swivel data set

4)

0 = yes: Operator must acknowledge the change

1 = no: calculated vectors are entered immediately (only effective if HUNDREDS

and THOUSANDS position = 0)

HUNDREDS: Measurement result display

5)

0 = No

1 = Yes

THOUSANDS: Measurement result display can be edited

0 = No

1 = Yes, and can be edited (only effective, if the HUNDREDS position = 1)

1)

All default values = 0 or marked as default=x

2)

Display depends on the general SD54760 $SNS_MEA_FUNCTION_MASK_PIECE.

3)

Using this version, for example, for 90 degree positions, the kinematics can be measured at the calibration ball, without

colliding with the retaining shaft of the calibration ball. A starting angle S_STA1 (0 to 360 degrees) can be entered. The

incremental angle when circling the ball is equal to 90 degrees.

As feedrate along the circular path, the channel-specific SD55634 $SCS_MEA_FEED_PLANE_VALUE is used

4)

There is an operator prompt with M0 before entering. The vectors are only entered with NC start.

If the measuring program is aborted with RESET no calculated vectors are entered.

Vectors are only entered when the tolerance of the offset vectors has not been exceeded during the calculation.

Work preparation

3.25 Programming cycles externally

NC programming

1186 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...