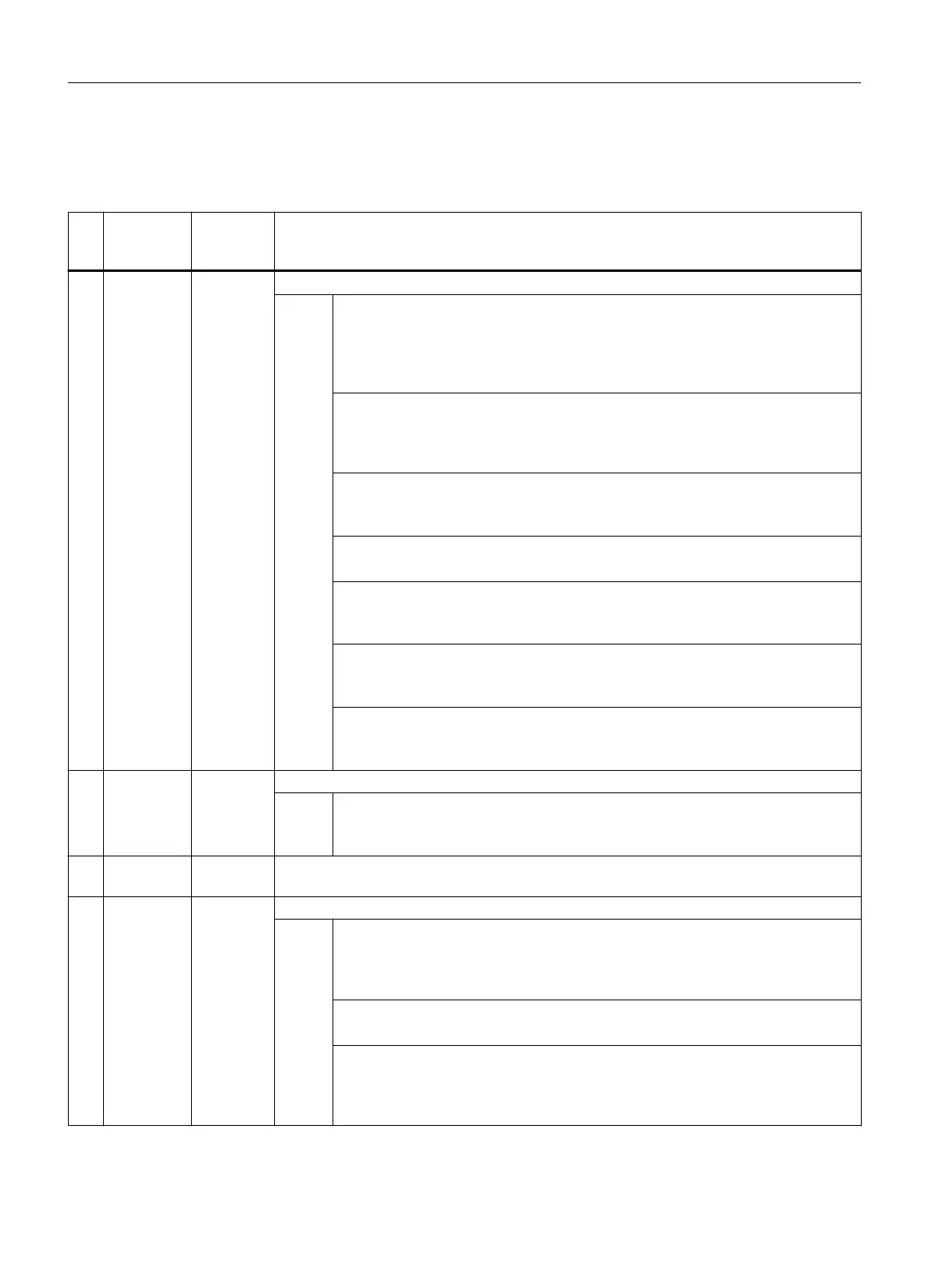

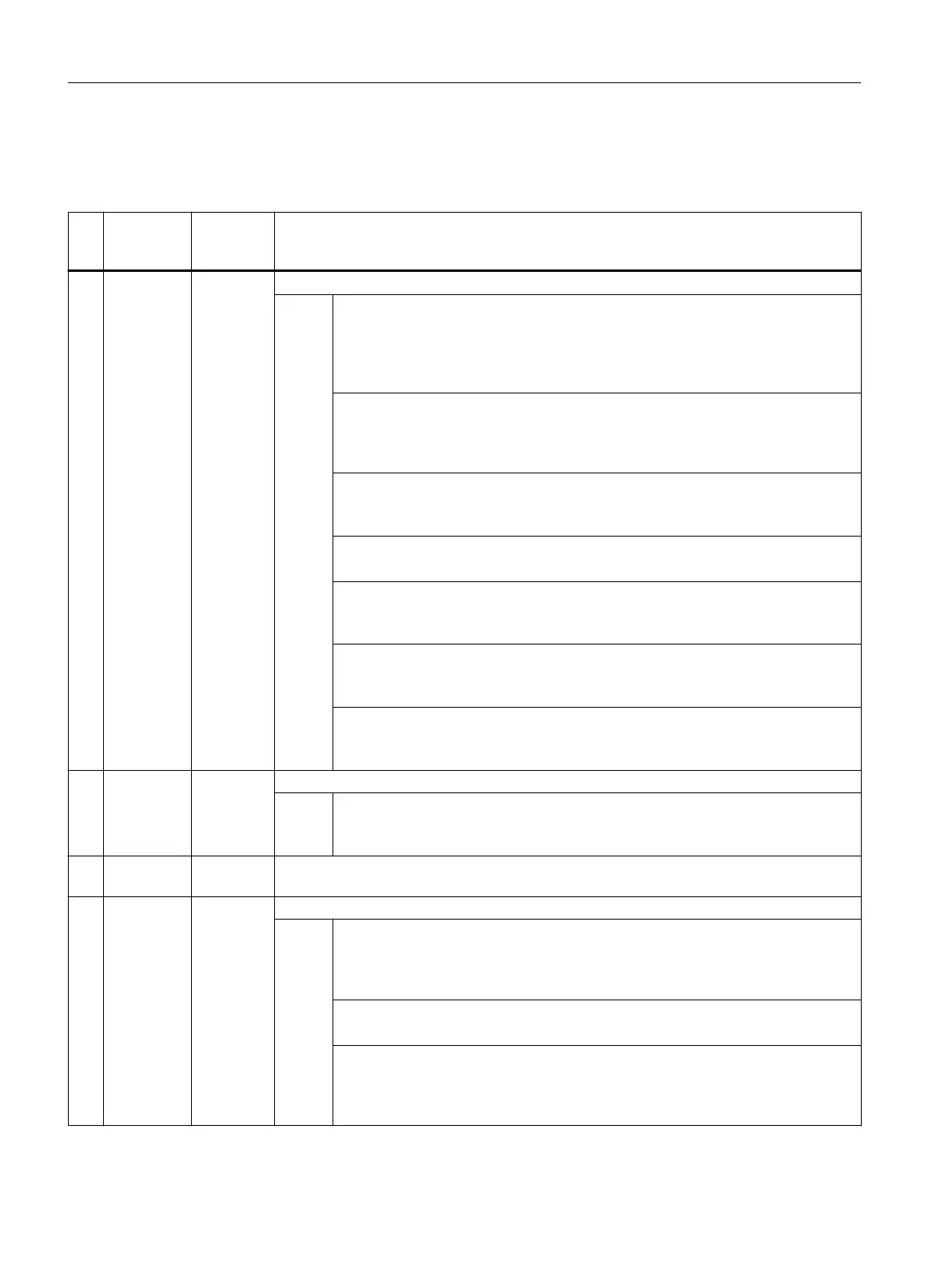

Table 3-22 CYCLE971 call parameters

1)

No. Screen

form pa‐

rameter

Cycle pa‐

rameter

Meaning

1 S_MVAR Measuring variant

Val‐

ues:

UNITS:

0 = Calibrate tool probe

1 = Measure tool with stationary spindle (length or radius)

2 = Measure tool with rotating spindle (length or radius), see parameters S_F1

to S_S4

TENS: Measurement in the machine coordinate system or workpiece coordinate

system

0 = Measurement in MCS (machine-related), measure tool or calibrate tool probe

1 = Measurement in WCS (workpiece-related), measure tool or calibrate tool probe

HUNDREDS: Individually check teeth

0 = No

1 = Yes

THOUSANDS:

0 = 0

TEN THOUSANDS: Incremental calibration or measurement

0 = No specification

1 = Incremental calibration or measurement

HUNDRED THOUSANDS: Calibrate tool probe automatically

0 = Do not calibrate tool probe automatically

1 = Calibrate tool probe automatically

ONE MILLION: Calibrating in the plane with spindle reversal

0 = Calibrating in the plane without spindle reversal

1 = Calibrating in the plane with spindle reversal

2 Selection S_KNUM Offset variant

2)

Val‐

ues:

UNITS: Tool offset

0 = No specification (tool offset in geometry)

1 = Tool offset in wear

3 Icon+

number

S_PRNUM Number of the field of the probe parameters (not probe number)

4 X0 S_MA Measuring axis, offset axis

4)

Val‐

ues:

UNITS: Number of the measuring axis

1 = 1st axis of the plane (for G17 X)

2 = 2nd axis of the plane (for G17 Y)

3 = 3rd axis of the plane (for G17 Z)

TENS:

0 = 0

HUNDREDS: Number of the offset axis

0 = Not an offset axis

1 = 1. axis of the plane (for G17 X)

2 = 2nd axis of the plane (for G17 Y)

Work preparation

3.25 Programming cycles externally

NC programming

1192 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...