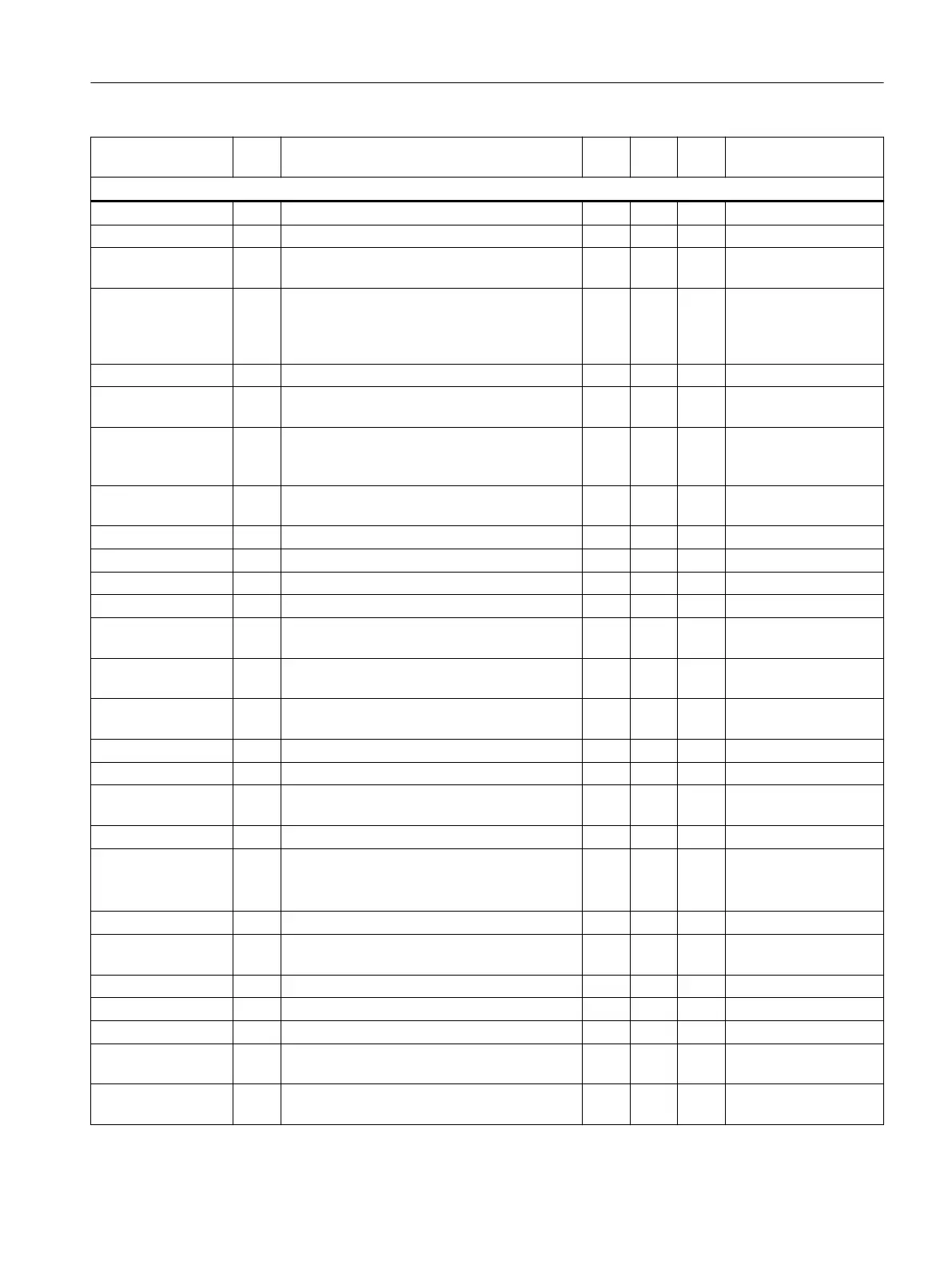

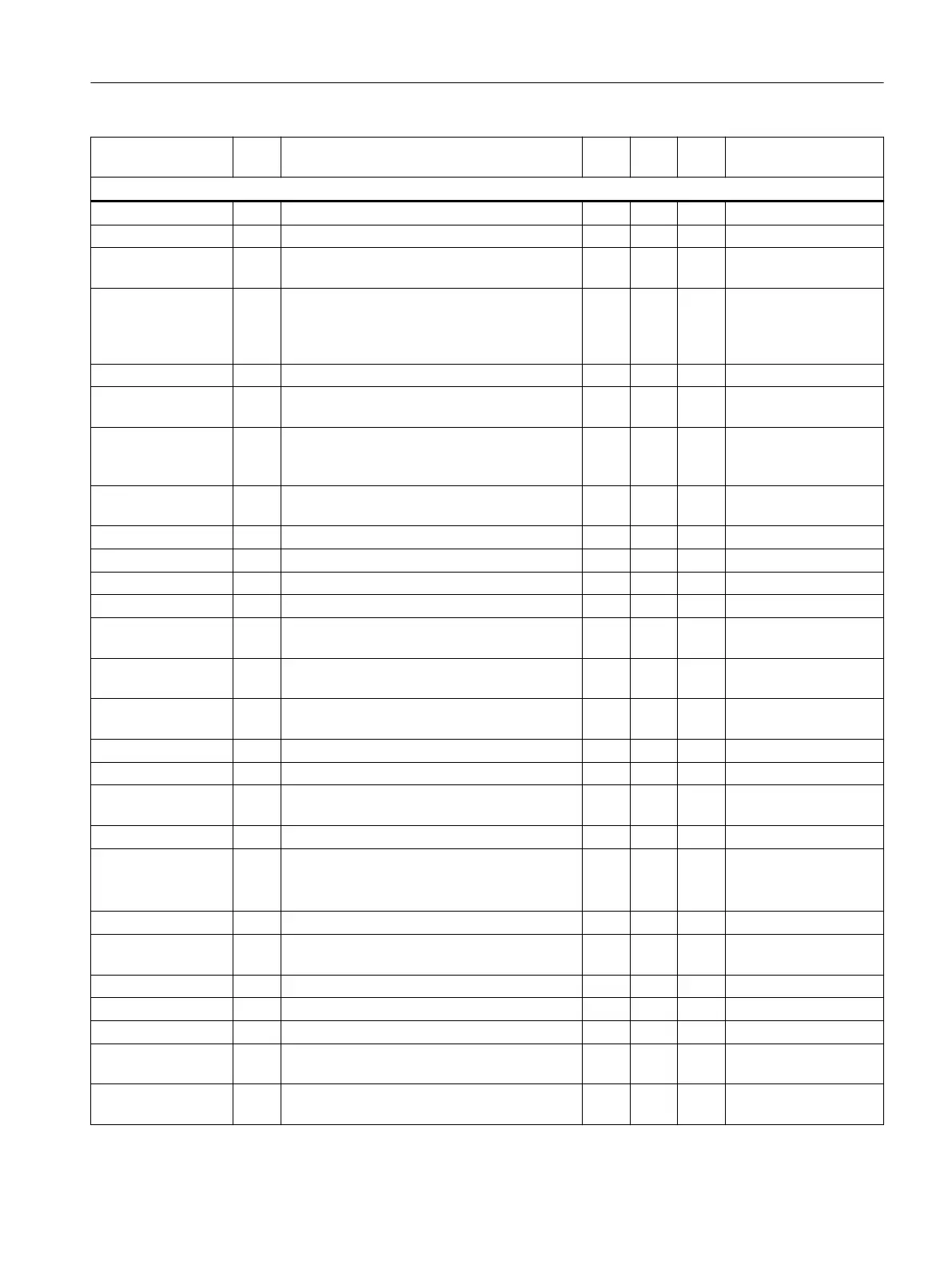

Operation Type

1)

Meaning W

2)

TP

3)

SA

4)

Description see

5)

1) 2) 3) 4) 5)

for explanations, see legend (Page 1197).

OSP2 K Oscillation right reversal point m + PM-NC

OSS G Tool orientation smoothing at end of block m + PM-NC

OSSE G Tool orientation smoothing at start and end of

block

m + PM-NC

OST G Smoothing of tool orientation by specifying an‐

gular tolerance in degrees with SD (maximum

deviation from programmed orientation char‐

acteristic)

m + PM-NC

OST1 K Oscillating: Stopping point in left reversal point m + PM-NC

OST2 K Oscillating: Stopping point in right reversal

point

m + PM-NC

OTOL A Orientation tolerance for compressor func‐

tions, orientation smoothing and smoothing

types

m + - PM-NC

OTOLG0 A Orientation tolerance for rapid traverse move‐

ments

m + - PM-NC

OVR K Speed offset m + PM-NC

OVRA K Axial speed offset m + + PM-NC

OVRRAP K Rapid traverse override m + PM-NC

P A Number of subprogram repetitions + PM-NC

PAROT G Align workpiece coordinate system on work‐

piece

m + PM-NC

PAROTOF

6)

G Deactivate frame rotation in relation to work‐

piece

m + PM-NC

PCALL K Call subprograms with absolute path and pa‐

rameter transfer

+ PM-NC

PDELAYOF G Punching with delay OFF m + PM-NC

PDELAYON

6)

G Punching with delay ON m + PM-NC

PHI K Angle of rotation of the orientation around the

direction axis of the taper

+ PM-NC

PHU K Physical unit of a variable + PM-NC

PL A 1. B spline: Node clearance

2. Polynomial interpolation Length of the pa‐

rameter interval for polynomial interpolation

s + PM-NC

PM K Per minute + PM-NC

PO K Polynomial coefficient for polynomial interpo‐

lation

s + PM-NC

POCKET3 C (T) Milling the rectangular pocket + PM-NC

POCKET4 C (T) Milling the circular pocket + PM-NC

POLF K LIFTFAST retraction position m + PM-NC

POLFA P Start retraction position of single axes with

$AA_ESR_TRIGGER

m + + PM-NC

POLFMASK P Enable axes for retraction without a connec‐

tion between the axes

m + - PM-NC

Tables

4.1 Operations

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1223

Loading...

Loading...