If the angles <W1> and <W2> are selected arbitrarily, the

cutting edge of the tool is generally not in the machining

plane. The angle γ through which the cutting edge is rotated

out of the machining plane, must not be greater than the limit

value which is defined by the setting data SD42999 $SC_OR‐

ISOLH_INCLINE_TOL.

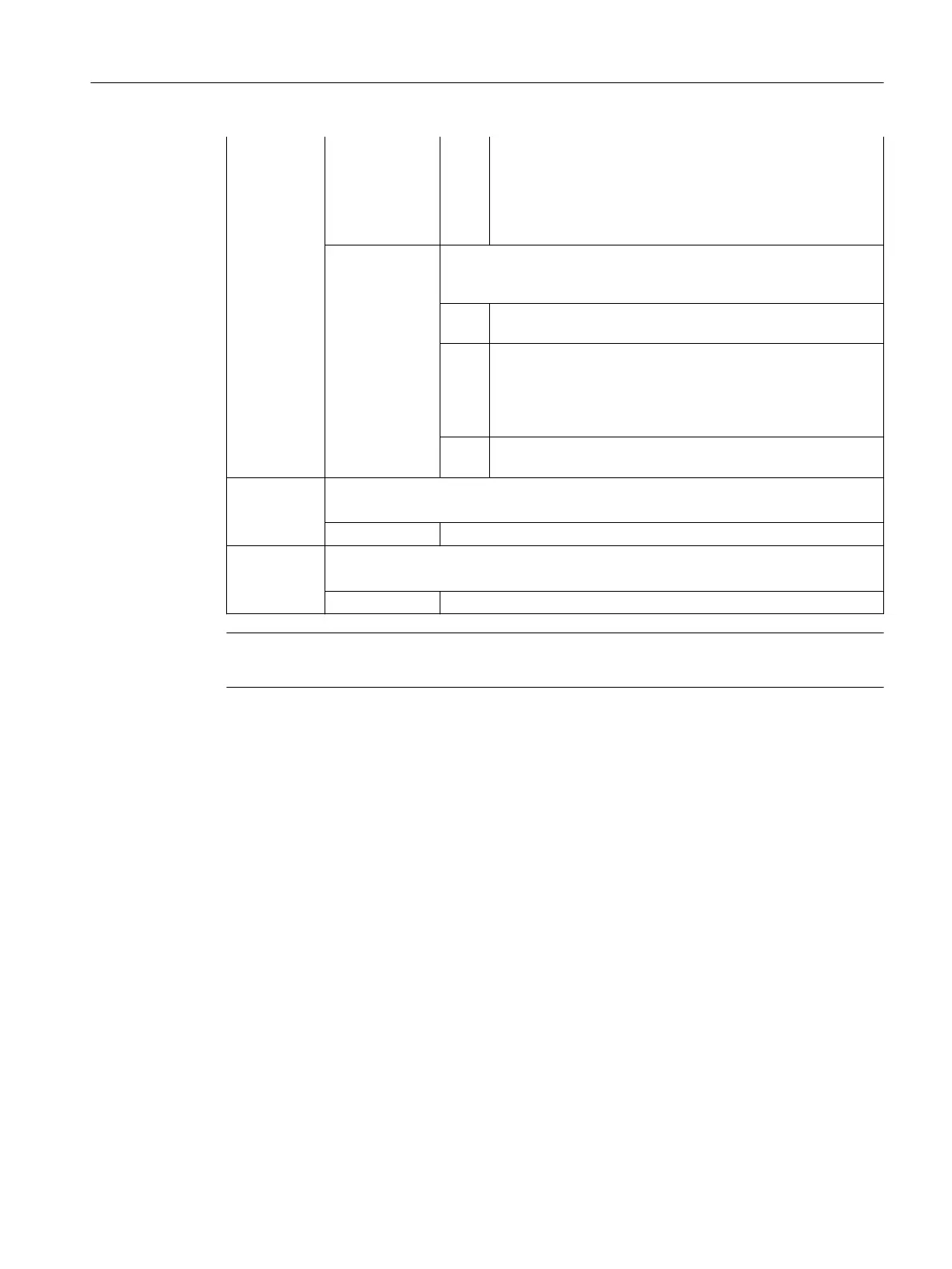

Thousands po‐

sition:

Specifies which positions of the solutions may be modified when the

hundreds position has the value "0", i.e. for the "Tool alignment"

function.

0xxx The calculated axis positions should be as close as possible

to the current machine axis positions.

1xxx The calculated axis positions for modulo axes should be as

close as possible to the middle of the modulo range, for other

axes as close as possible to 0. For non-modulo axes, this

means that the axis positions are reduced to the range

-180° … +180°.

2xxx The calculated axis positions should be reduced to the range

-180° … +180° irrespective of the axis type.

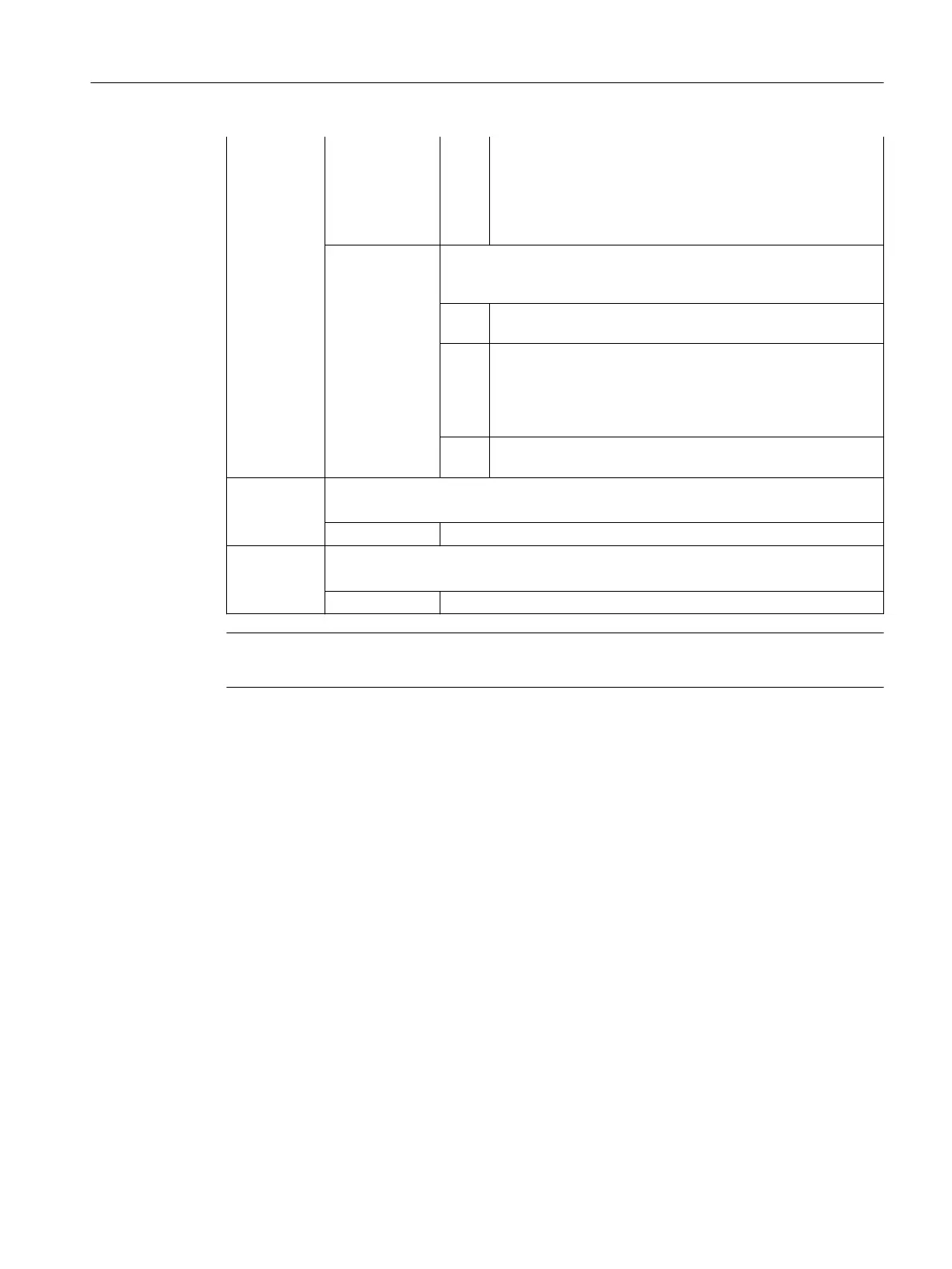

<W1>: First angle

The meaning results from the hundreds position of the <Cntrl> paramter.

Data type: REAL

<W1>: Second angle

The meaning results from the hundreds position of the <Cntrl> paramter.

Data type: REAL

Note

Parameters that have not been programmed have the default value "0".

Work preparation

3.13 Tool offsets

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 795

Loading...

Loading...