However, since the wear is evaluated negatively, due to setting data SD42930

$SC_WEAR_SIGN, the compensation determined in this way has to be entered in the

compensation memory with a negative sign. The contents of the relevant tool parameters at the

end of the program are thus:

$TC_DP3[1,1]: 10.000 ; geometry L1 (unchanged)

$TC_DP4[1,1] : 15.000 ; geometry L2 (unchanged)

$TC_DP5[1,1]: 10.000 ; geometry L3 (unchanged)

$TC_DP12[1,1] : 2.010 ; wear L1 (= 10 - 15 * cos(30) + 10 * sin(30))

$TC_DP13[1,1] : -16.160 ; wear L2 (= -15 * sin(30) - 10 * cos(30))

$TC_DP14[1,1] : -5.000 ; wear L3

The effect of setting data SD42930 $SC_WEAR_SIGN on the L3 component in the Y direction

can be recognized without the additional complication caused by the frame rotation.

Additional information

Turning/grinding tools: Calculating the tool length depending on MD20360

$MC_TOOL_PARAMETER_DEF_MASK

The following machine data defines how the wear and tool length are to be evaluated if a

diameter axis is used for turning/grinding tools:

MD20360 $MC_TOOL_PARAMETER_DEF_MASK.<Bit> = <Value>

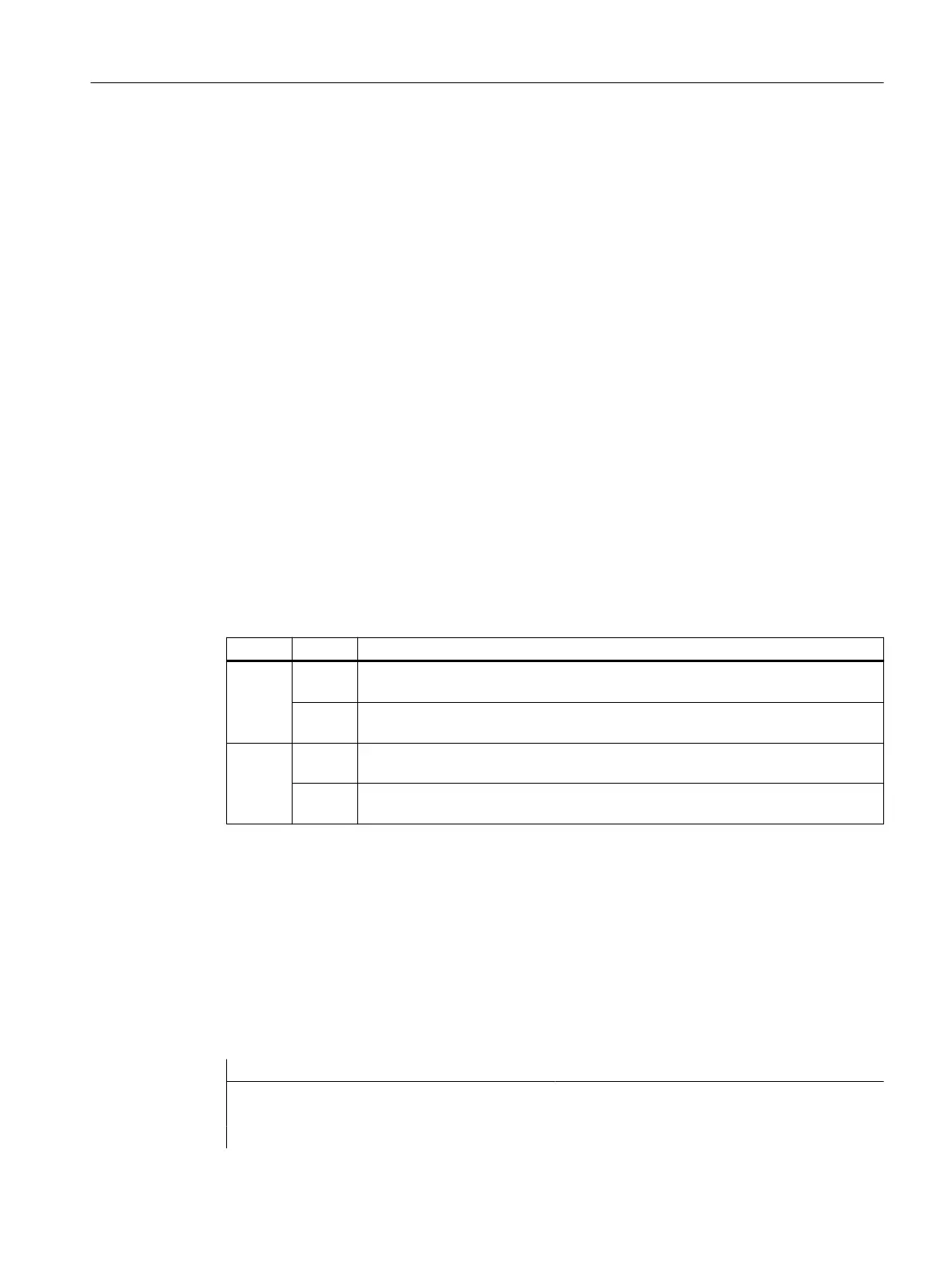

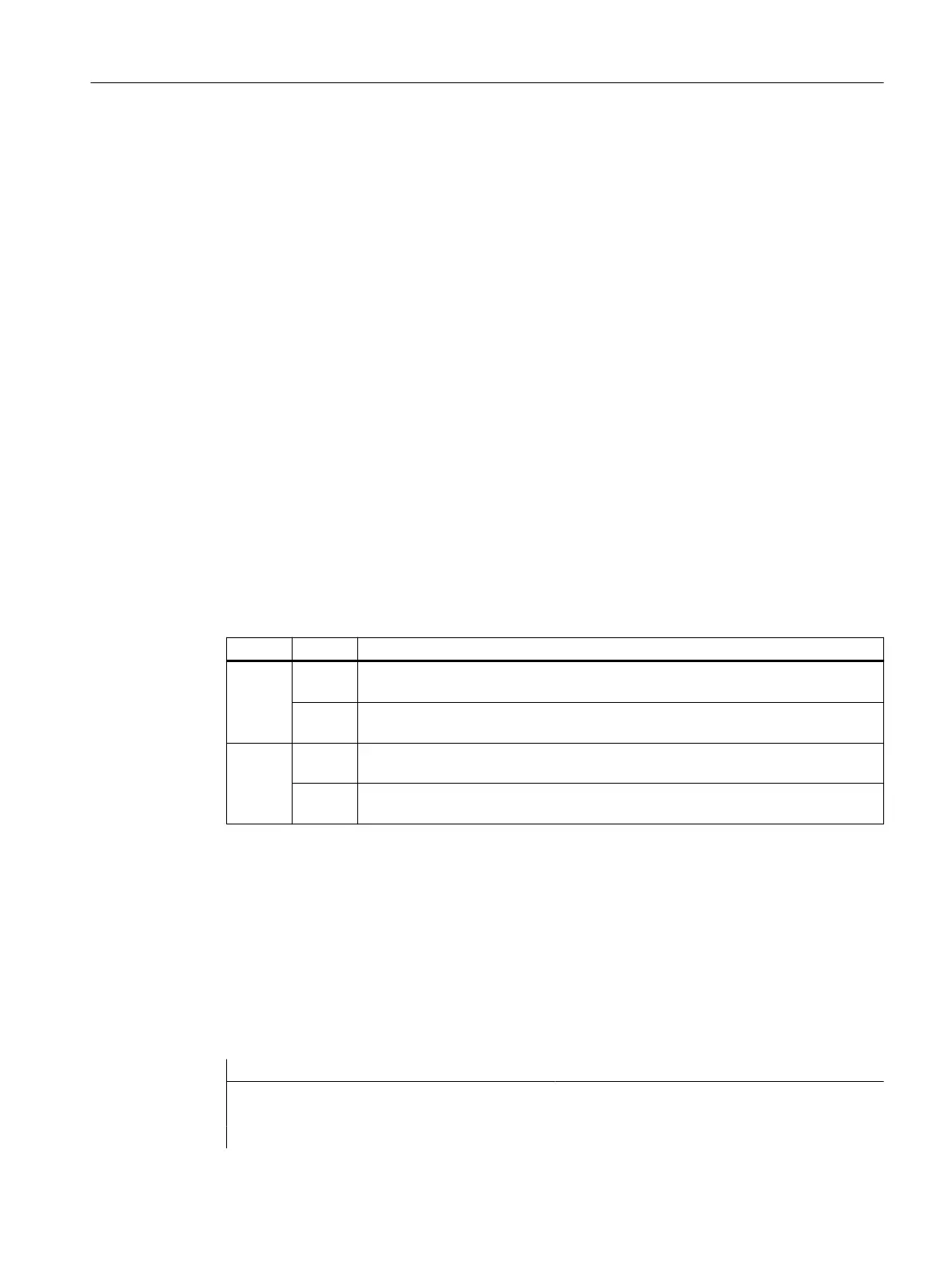

<Bit> <Value> Meaning

0

0 For turning/grinding tools, the wear parameter of the transverse axis is taken into

account in the radius value:

1 For turning/grinding tools, the wear parameter of the transverse axis is taken into

account as the diameter value:

1 0 For turning/grinding tools, the tool length component of the transverse axis is taken

into account as the radius value:

1 For turning/grinding tools, the tool length component of the transverse axis is taken

into account as the diameter value:

If the bits involved are set, the associated entry is weighted with a factor of 0.5. The correction

using SETTCOR is executed so that the total effective tool length change is equal to the value

transferred in <CorVal>. If, when calculating the length, a length is evaluated with a factor of 0.5

as a result of machine data MD20360 $MC_TOOL_PARAMETER_DEF_MASK, then the

compensation of this component must be realized with twice the value transferred.

Example

MD20360 $MC_TOOL_PARAMETER_DEF_MASK = 2 (tool length must be evaluated in the

diameter axis using a factor of 0.5)

Axis X is the diameter axis.

Program code Comment

N10 DEF REAL _LEN[11]

N20 DEF REAL _CORVAL[3]

N30 $TC_DP1[1,1]=500 ; Tool type

Work preparation

3.13 Tool offsets

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 829

Loading...

Loading...