Programming and Operating Manual (Turning)

01/2017

187

When the contour is machined through finishing and roughing, finishing is performed in the same direction as roughing,

dependent on the setting of the VARI parameter; however, if the contour is machined through finishing only, the direction of

machining is determined by the programmed direction, independent of the setting of the VARI parameter. The tool radius

compensation can be selected (G41/G42) and deselected (G40) via the following USER DATA:

● _ZSD[13] = 0: roughing and finishing in G41/G42 mode

● _ZSD[13] = 1 (default): roughing in G40 mode and finishing in G41/G42 mode

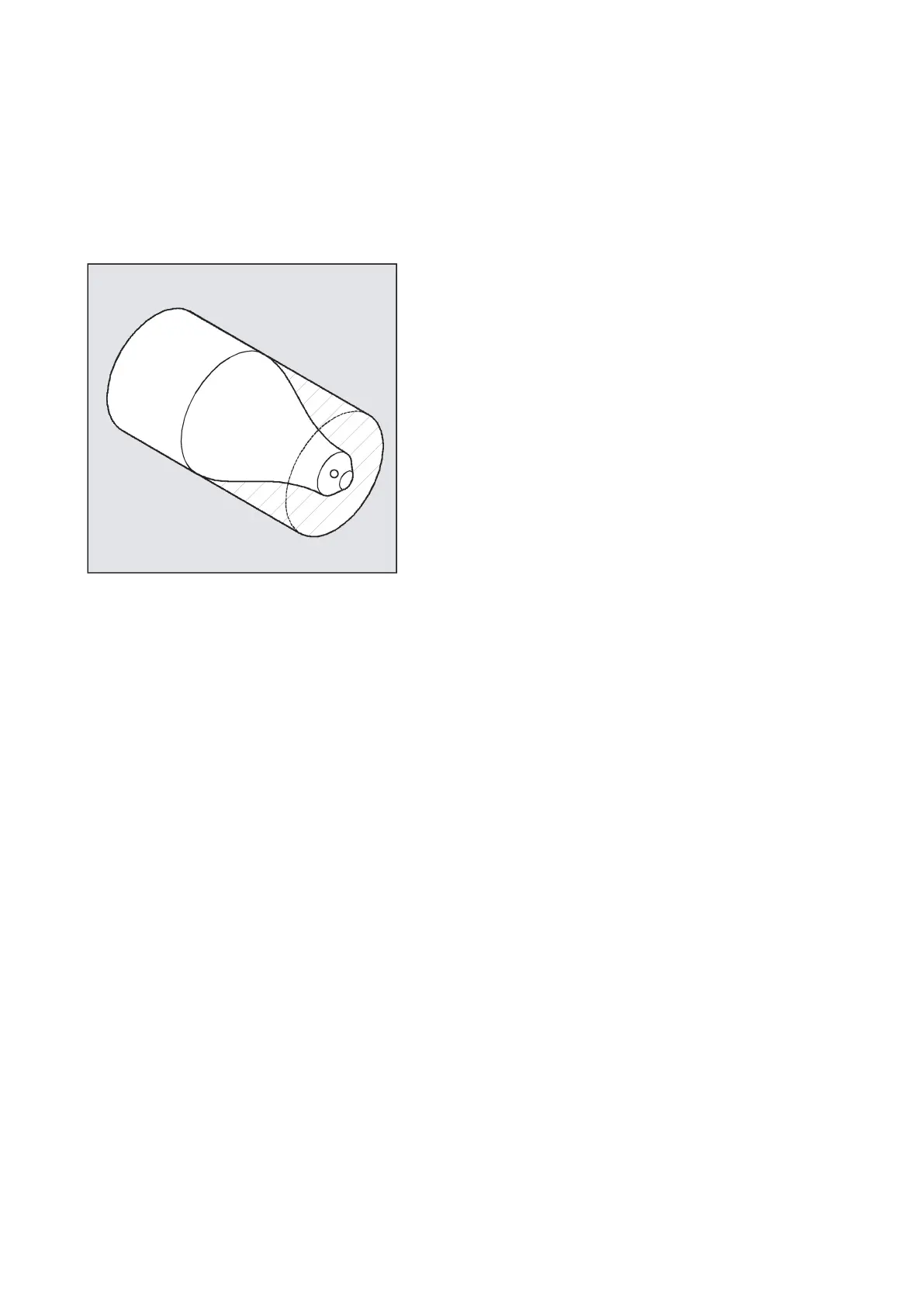

See the following illustration for CYCLE95:

Sequence

Position reached prior to cycle start:

The starting position is any position from which the starting point of the contour can be approached without collision.

The cycle creates the following sequence of motions:

The cycle starting point is calculated internally and approached with G0 in both axes at the same time.

Roughing without relief cut elements:

● The paraxial infeed to the current depth is calculated internally and approached with G0.

● Approach of paraxial roughing intersection point with G1 and at feedrate FF1.

● Rounding parallel to the contour along the contour + finishing allowance with G1/G2/G3 and FF1.

● Lift-off by the amount programmed under _VRT in each axis and retraction with G0.

● This sequence is repeated until the total depth of the machining step is reached.

● When roughing without relief cut elements, retraction to the cycle starting point is carried out axis by axis.

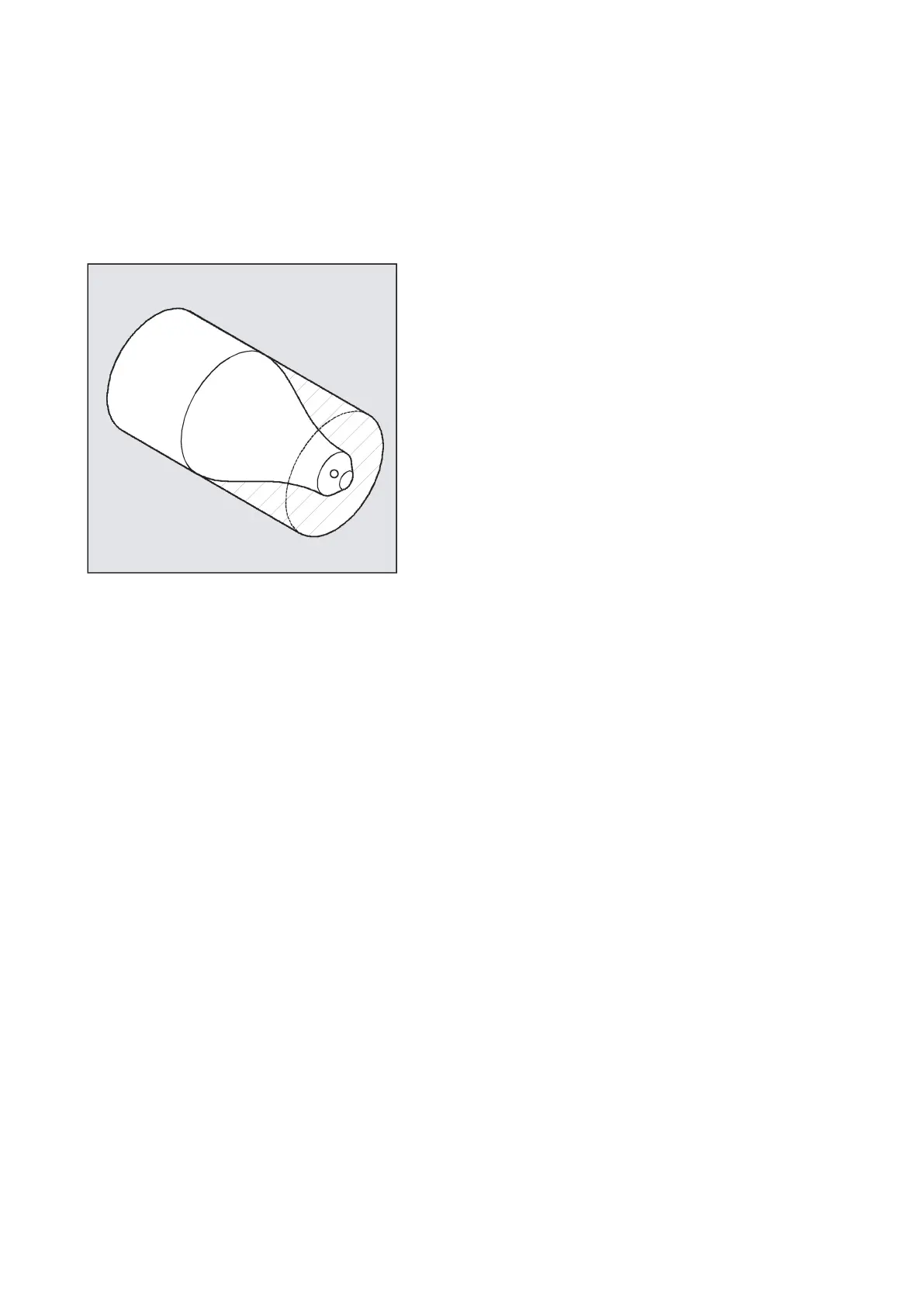

See the following illustration for the sequence of operation for CYCLE95:

Loading...

Loading...