EA180 Servo Drive Manual

100

Whether there is serious interference

Use a qualified twisted shielded wire to transmit the

pulse signal

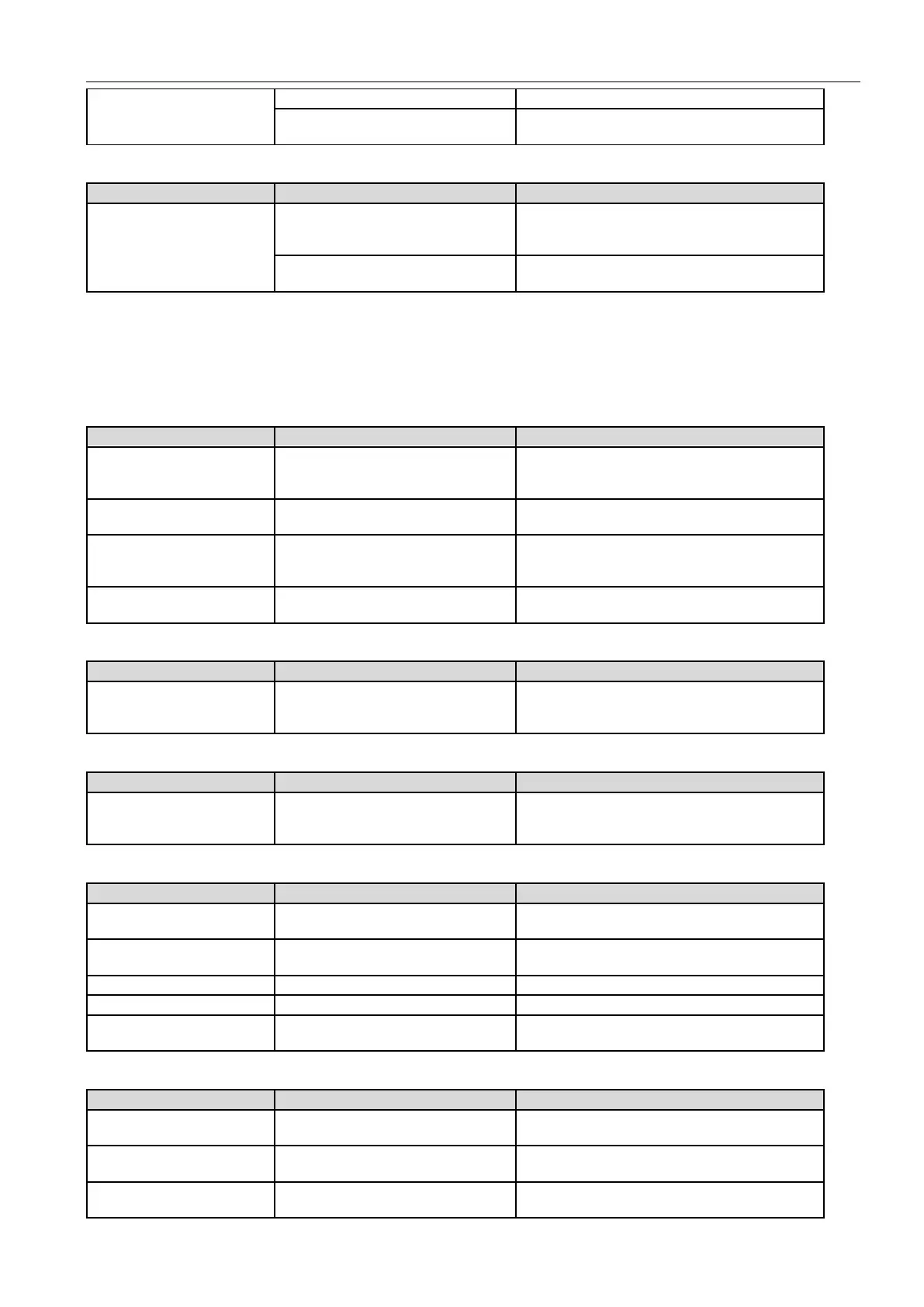

Al 034: Analog zero drift error correction

For zero drift self-learning, the

collected external voltage

exceeds 2V

When performing the autotuning of zero

drift, whether the upper computer

command is set to 0

The commands from the upper computer is set

to 0, and then auto tune the zero drift again.

Upper PC command is 0, the output

voltage exceeds 2V

Modify the upper computer output

Warning diagnosis and handling measures

When the servo drive has a warning, a warning will be displayed "AlE on the numeric keypad. " warning occurance indicates that the

system detects an abnormality, but the motor does not stop running, please check the causes and eliminate the problem of warning.

Warning display and handle measures are as follows:

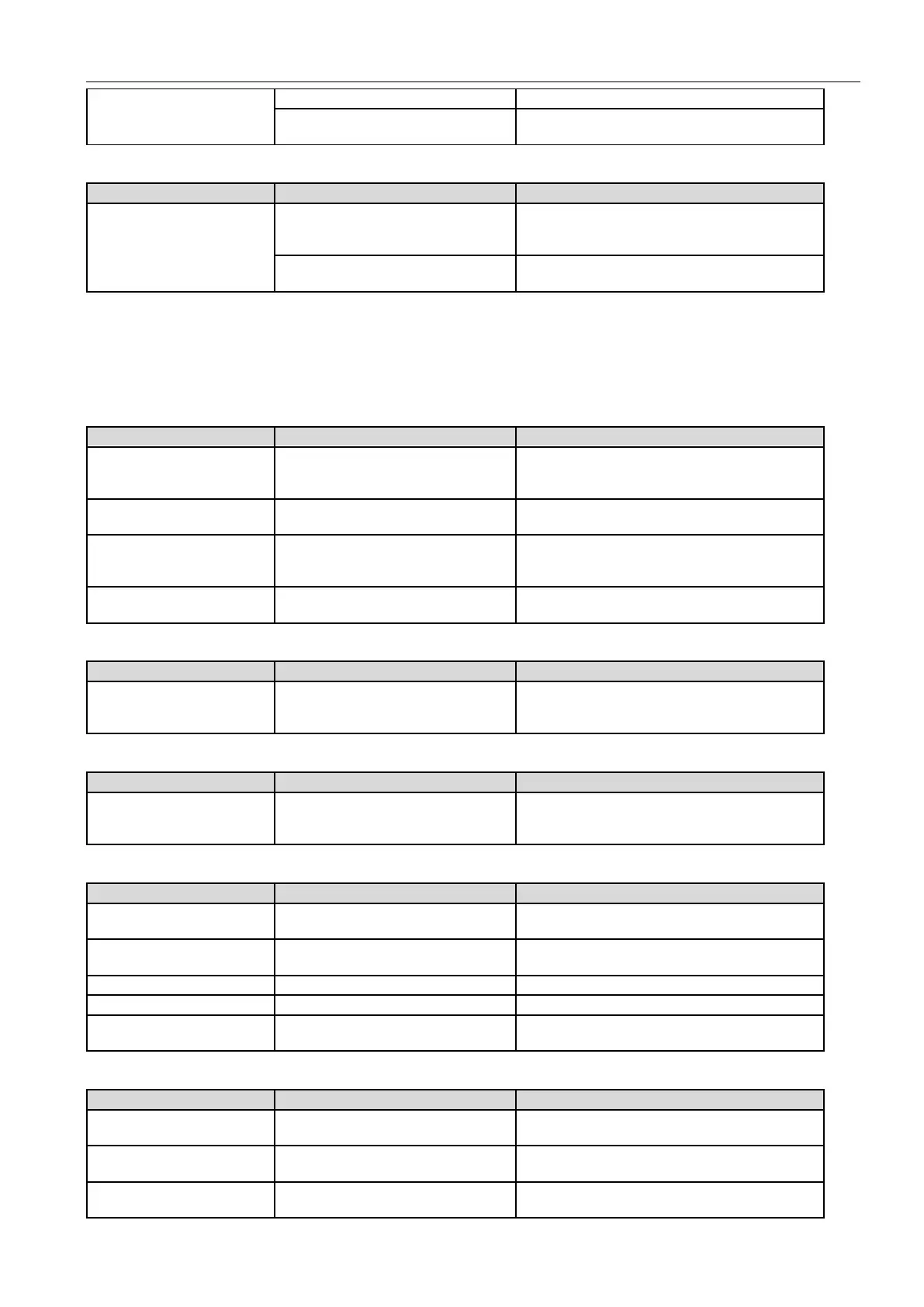

AlE02: Drive overheating warning

Ambient temperature is too high

Check whether the ambient temperature

and humidity are within the allowable

range

Improve the cooling conditions of the servo drive, and

reduce the ambient temperature

The drive cooling fan is

damaged

Check if the drive cooling fan is running

Replace the fan that does not operate

The installation direction of the

servo drive or the cooling fan

inlet and outlet are blocked

1: Check the drive installation meets the

requirements

2: Check the drive sink is clogged

1: installing a drive in accordance with chapter 2.

2: blockage cleansed

The servo drive is faulty

Power off for a period of time before

restart

If the fault is still reported, replace the servo drive

AlE03: Motor overload warning

motor load reaches at the motor

overload warning threshold set

by P8-09

1: Refer to Al 00D and Al 00E

2: P8-09 parameter setting is too small

1: Refer to Al 00D and Al 00E

2: Appropriate increase in P8-09 set value

AlE04: drive overload warning

drive load reaches at the drive

overload warning threshold set

by P8-08

1: Refer to Al 00D and Al 00E

2: P8-08 parameter setting is too small

1: Refer to Al 00D and Al 00E

2: Appropriate increase in P8-08 setting value

AlE05: Excessive position deviation warning

The position following error

alarm threshold is too small

Confirm whether the parameter of P1-18

is appropriate

Increase the setting value of P1-18

The pulse command frequency

is higher than the specification

Detect the frequency of the pulse

command

Adjust the pulse frequency so that it is not higher than

the specification

The gain value is set too low

Determine if the set value is appropriate

Set the gain value correctly

Confirm the torque limit value

Correctly adjust the torque limit value

Load inertia is too large

Calculate the ratio of load inertia to motor

rotor inertia

Reduce the load inertia or re-evaluate the motor

capacity

AlE06: braking overload warning

Braking resistor is not connected

or the capacity is too small

1: Check the braking resistor is connected

2: calculate the braking resistance value

1: Reconnect braking resistor

2: Use the appropriate braking resistor resistance

Load inertia is too large

Calculate if the total load / rotor inertia

ratio is appropriate

Reduce the load inertia or change the motor with

larger inertia

Incorrect parameter setting

Check brake resistor set value (P8-10) and

capacity parameter (P8-11)

Correctly set P8-10 and P8-11 parameters

Loading...

Loading...