EA180 Servo Drive Manual

75

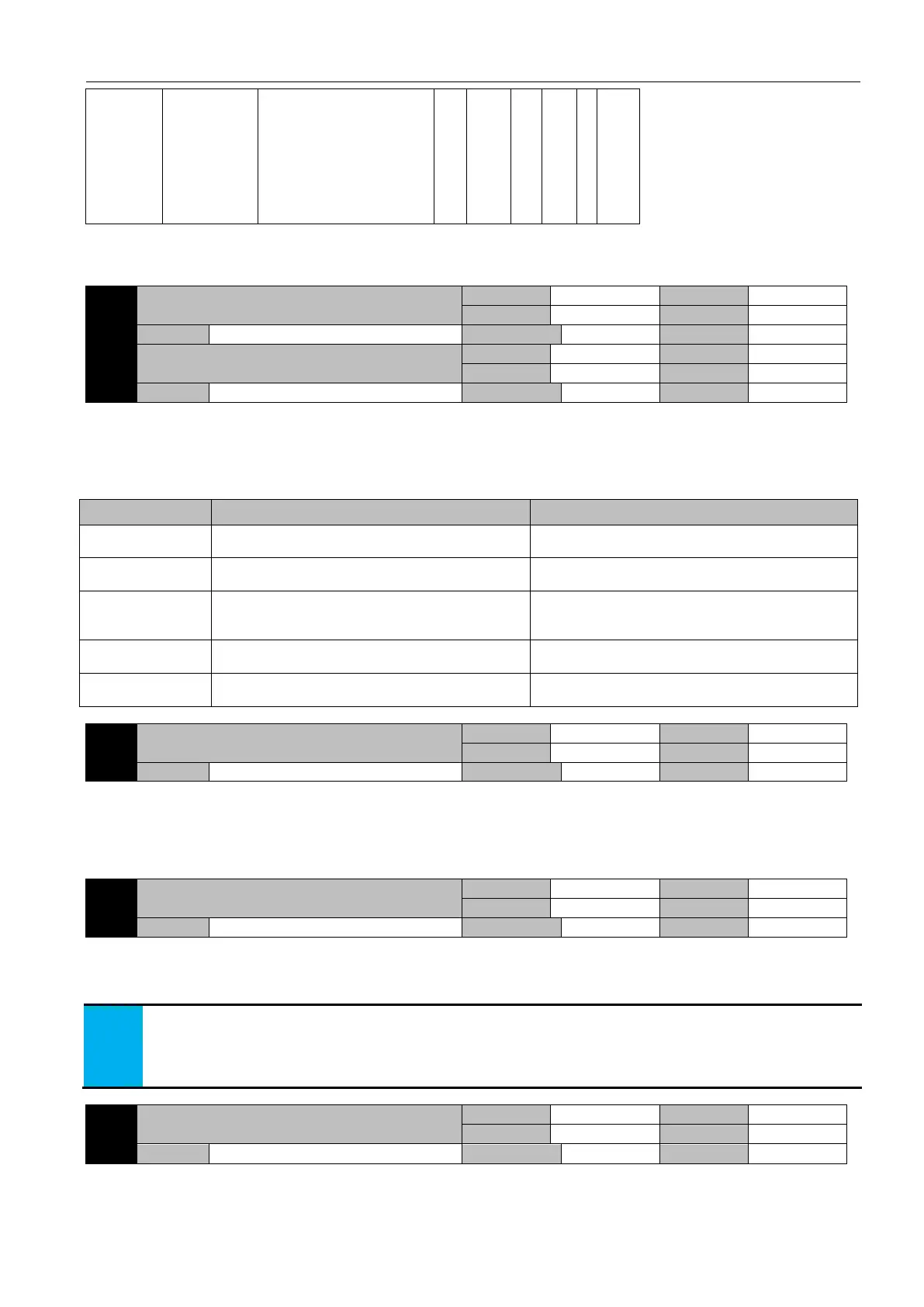

the high and

low bit setting

of 32-bit

function code

1:Read: high 16-bit first,then

low 16-bit

2:Read: low 16-bit first, then

high 16-bit; Write: on the

contrary

3:Read: high 16-bit first, then

low 16-bit; Write: on the

contrary

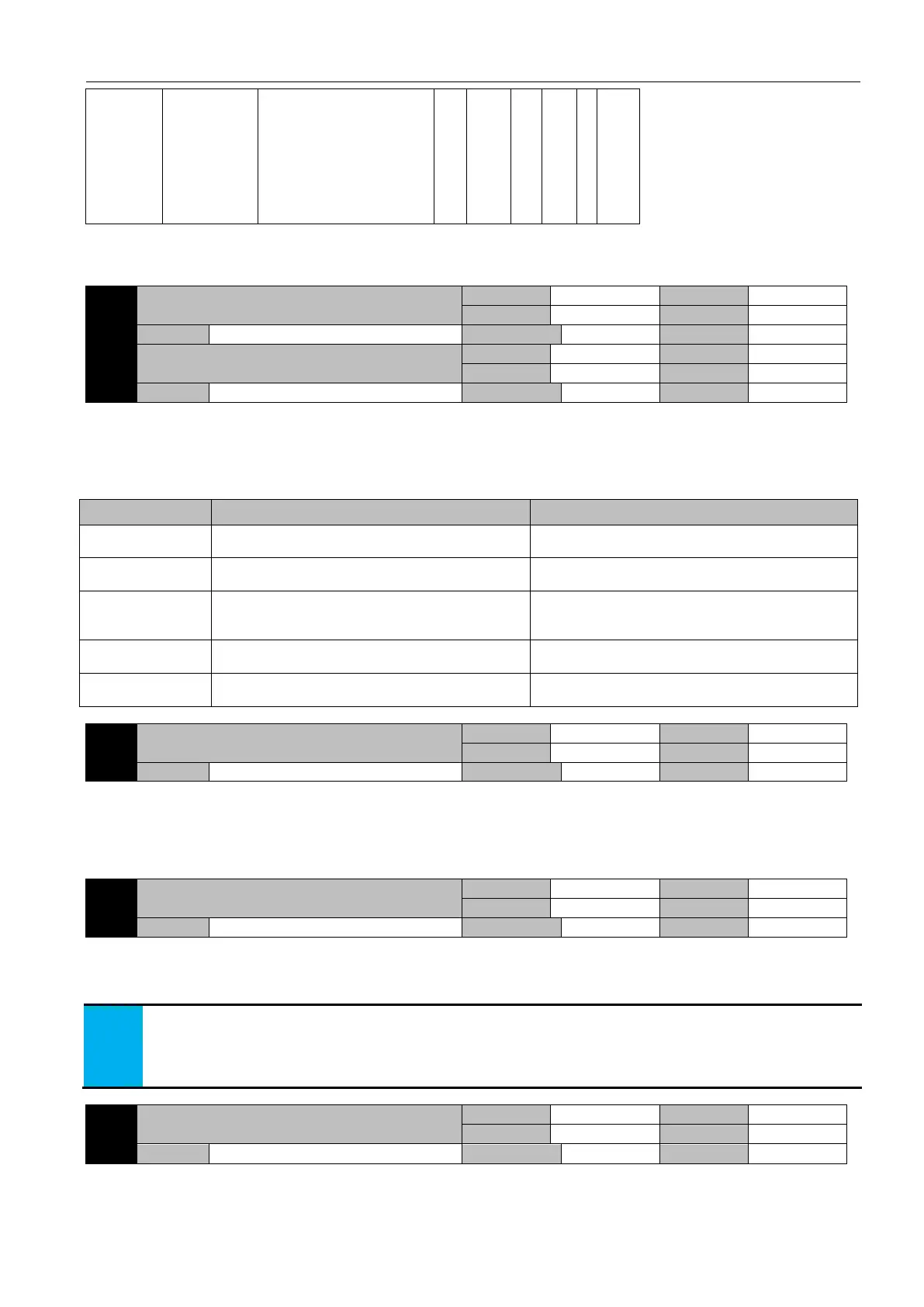

6.12 P8-xx Extended function parameters

Parameter function:

Set the motor speed and acceleration and deceleration time of the JOG, the acceleration and deceleration time reference is the

motor speed time from 0 to the rated speed or vice versa. The drive can carry out inching through the function parameter AF-02 when

the servo is enabled OFF, or by the DI terminal set to JOG-P and JOG-N when the servo is enabled ON or OFF.

Jogging command execution:

JOG terminal OFF→ON and on

The speed at which to run from P8-01 to P8-00, and

continuously running

Slow down to zero speed at the speed of P8-01, restore

to original control mode

Position mode of

pulse command

Clear droop pulses, starting at the current speed, run

from P8-01 to P8-00, and run continuously.

Resume position mode the moment when JOG

command inactive, start receiving the command pulse.

Multi-stage position

mode

Clear droop pulses, starting at the current speed, run

from P8-01 to P8-00, and run continuously.

Restore the multi-stage position mode, run the

remaining pulse command, (the cleared stranded pulse

is no longer executed)

The speed at which to run from P8-01 to P8-00, and

continuously running

Accelerate by P2-04 or decelerate by P2-05 to the

specific speed of current speed command.

Starting from current speed, run from P8-01 to P8-00,

and continuously running.

Resume torque mode, and run according to the current

torque command

Auto tuning torque identified by offline inertia

Parameter function:

When the load inertia ratio is offline, the percentage of the torque relative to the motor's rated torque is the output torque of the

motor.

The greater the setpoint, the greater the possible mechanical impact, but the shorter the identification time and the number of

turns required by the motor, please set the appropriate value according to the machine.

The maximum number of turns identified by offline

inertia

Parameter function:Sets the maximum number of cycles allowed for off-line inertia identification

If the motor runs in this loop, the system inertia is not recognized successfully, or, in the course of inertia identification, the motor

cannot run to this circle, then Al028 alarm occurs.

When the system inertia can not be recognized, and the mechanical condition allows the motor to rotate more turns, please

increase the set value of this parameter.

When the system inertia can not be recognized, and the mechanical condition does not allow the motor to rotate more turns,

please add the set value of P8-02.

See section 6.6 for reference.

Absolute encoder maximum number of revolutions

Parameter Function: Set the upper limit of the turns of absolute encoder

If the number of revolutions of the absolute encoder is positive and its value exceeds the set value and the current command

direction is positive, the forward overtravel is processed. LED display p-ot, WARN terminal output is valid; if the number of

Loading...

Loading...