Instruction Manual

for

AS380 Series Elevator Integrated Drive Controller

184

◆ Check whether the door lock loop is normal;

◆ Check whether the leveling switch signal is normal;

◆ The elevator status on the handheld programmer should show "Inspection";

If abnormal, please check and correct accordingly.

8.4 Configuration of System Basic Parameters and Self Study of Motor Parameters

8.4.1 Configuration of System Basic Parameters

First set the system basic parameters in Table 7.2 correctly through a dedicated handheld

LCD Manipulator (see Chapter 5 for the use of hand-held Manipulator), and then make

commissioning as described in the following sections. For each new system, before setting

parameters, it’s recommended to make a parameter reset through a dedicated LCD Manipulator.

Parameter reset as follows:

(1) The elevator is in stop state;

(2) Find "parameter reset" command interface in handheld Manipulator;

(3) Align the cursor with "parameter reset" command and press Enter key, the system will

complete parameter reset immediately.

After parameter reset, all the parameters are changed into factory default values. Configure the

basic parameters on the basis of parameter reset, and the other parameters are set to be the factory

default values, to ensure normal and reliable operation of the system.

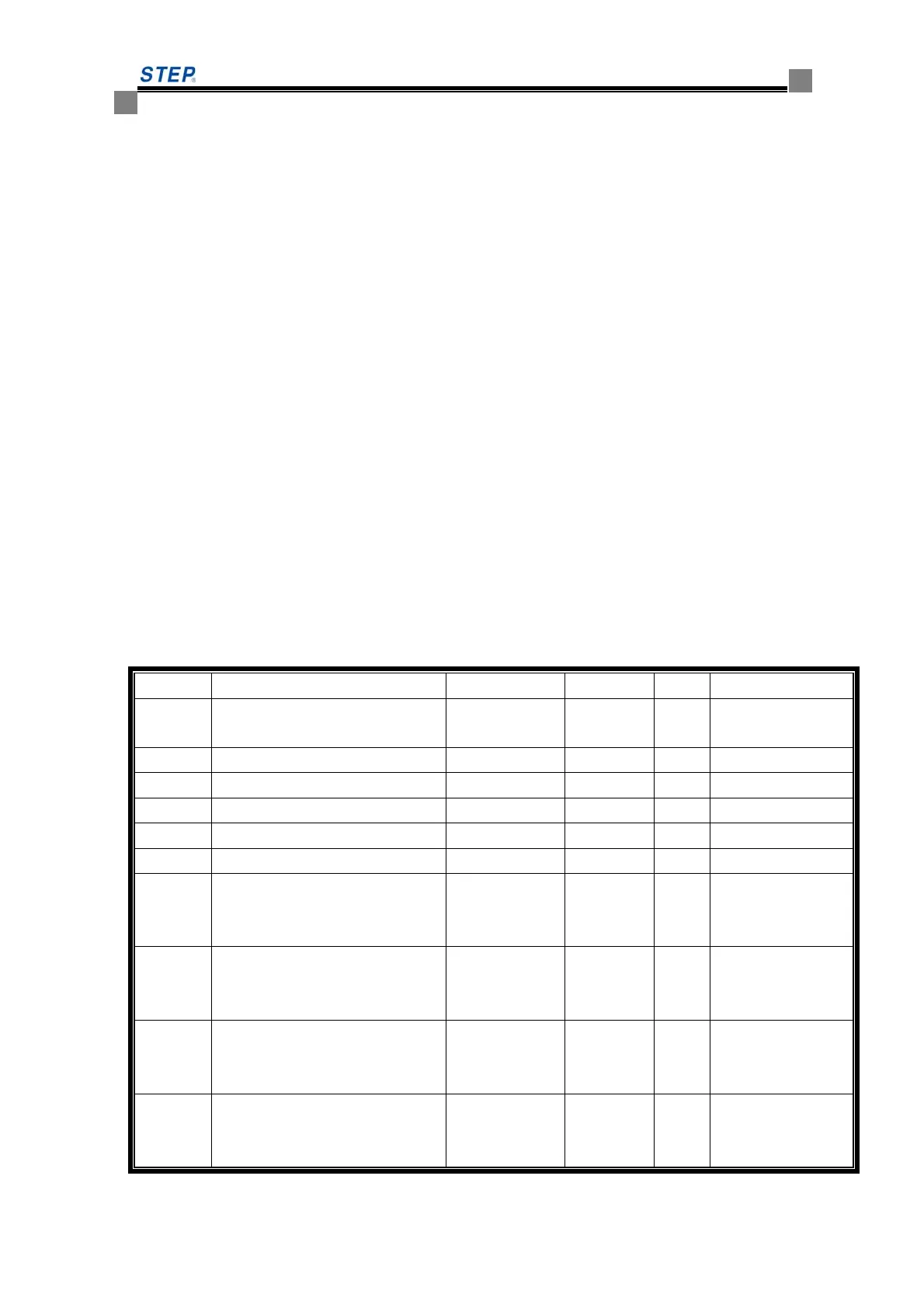

Table 8.2 System Basic Parameters

No. Name Default Value Scope Unit Remarks

F06

Elevator rated speed

1.750

0.100~

10.000

m/s

F09 Lockout floor 1

1~64

×

F10 Offset floor 0

0~64

×

F11 Total floor number preset 18

2~64

×

F12 Inspection speed 0.250

0~0.630

m/s

F23 Group control mode 0

0~3

×

F25

Input Type 1 (normal open or normal

closed configuration for X0 ~ X15

input point)

819

0~65535

×

F26

Input Type 2 (normal open or normal

closed configuration for X16 ~ X25

input point)

2

0~65535

×

F27

Lift car board input type (normal open

or normal closed configuration for

GX0 ~ GX15 input point)

0

0~65535

×

F28

Car top board input type (normal open

or normal closed configuration for

HX0 ~ HX15 input point)

327

0~65535

×

Loading...

Loading...