Instruction Manual

for

AS380 Series Elevator Integrated Drive Controller

232

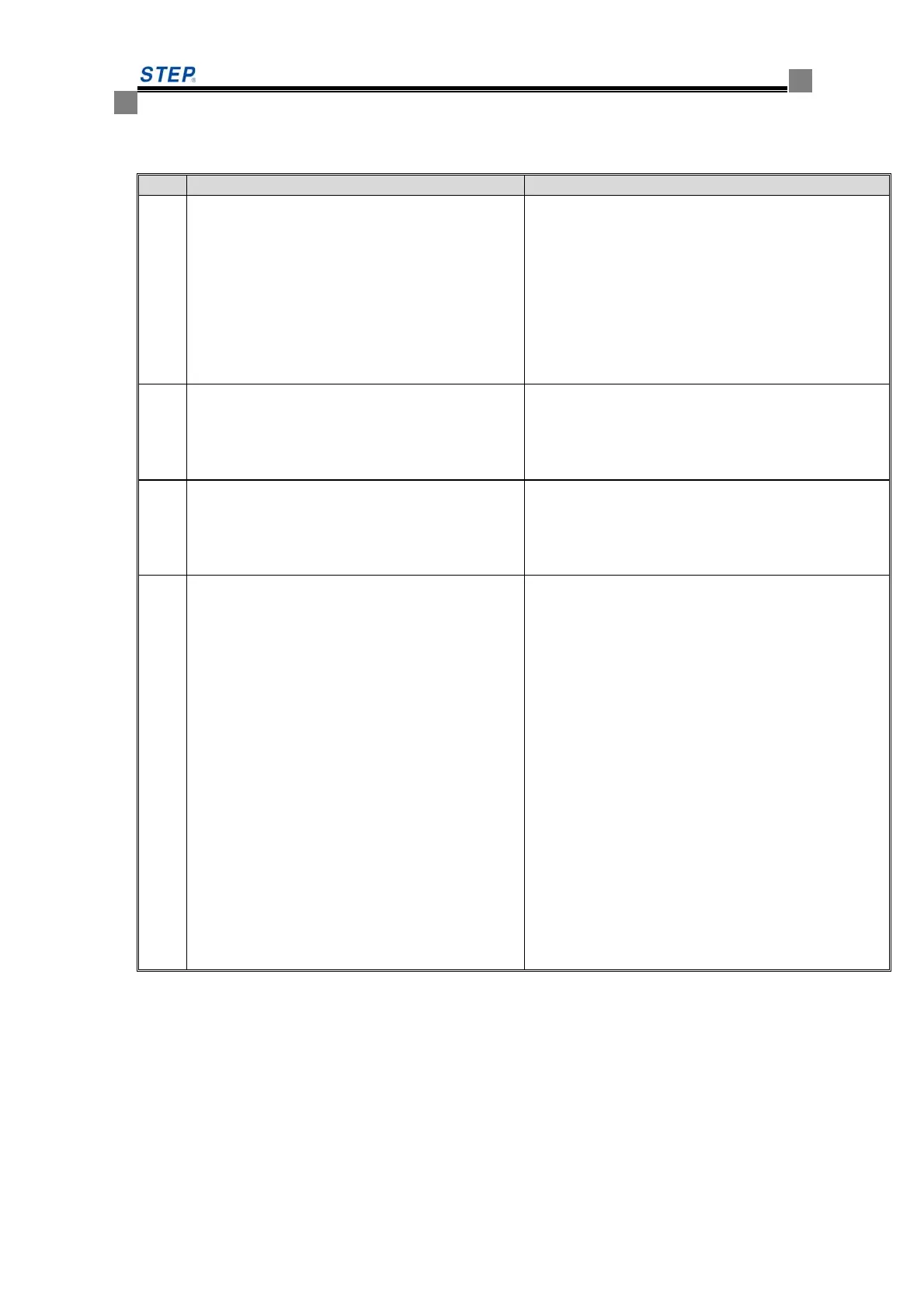

See attached Table A1.1 for basic noise suppression measures.

Attached Table A1.1 Basic Noise Suppression Measures.

No. Causes Measures

①

⑦

⑧

Due to electromagnetic induction and

electrostatic induction where signal lines are

arranged in duplex with power lines or arranged

in bundle, noises occurs and transmits in signal

line and additionally results in malfunction of

peripherals

1. Avoid arranging signal line and power line in

duplex and in bundle.

2. keep susceptible peripherals far away from

elevator integrated drive controller;

3. keep susceptible signal line far away from the

input/output cable of elevator integrated drive

controller;

4. Use shielded lines as signal line and power line.

It is better to put them in metal hoses (hose-to-hose

spacing shall not be less than 20cm )

②

Where closed loop circuit is formed among

peripherals and elevator integrated drive

controller, the grounding leakage current of

integrated drive controller may cause malfunction

of peripherals.

If that time the peripherals are not grounded, the

malfunction due to leakage current may be avoided.

③

When peripherals sharing a power supply system

with elevator integrated drive controller, the

noise of elevator integrated drive controller may

transit along the supply line and resultantly cause

malfunction of the related peripherals.

Connect a noise filter at the input side of elevator

integrated drive controller; or isolate the peripheral

from noise by isolating transformer/supply filter.

④

⑤

⑥

When such weak voltage equipment as control

computers, measuring gauges, radio sets and

sensor and their signal lines are installed in a

same control cabinet with elevator integrated

drive controller and are wired very close to each

other, the radiated interference may cause

malfunction of peripheral.

1. Susceptible peripherals and their signal lines must

e arranged far away from elevator integrated drive

controller. Furthermore, the signal line shall be of type

shielded line which shielding layer is properly

grounded. Signal line shall be threaded into metal hose

and arranged far away from the input/output cable of

elevator integrated drive controller. These two kinds of

cable shall be perpendicular to each other.

2. radio noise filter and linear noise filter (ferrite

common mode choke) as installed at both input side

and output side of elevator integrated drive controller

will be effective for suppress its noise radiation;

3. the cables of elevator integrated drive controller

shall be arranged in thicker shielding layer such as

ducts with thickness 2mm or be embedded in cement

tray. In addition, the cables must be threaded in

grounded metal hose. (Four-core cable may be

appreciable for motor cable. One end of a core

conductor shall be grounded to the elevator integrated

drive controller side and another end shall be

connected to motor casing.

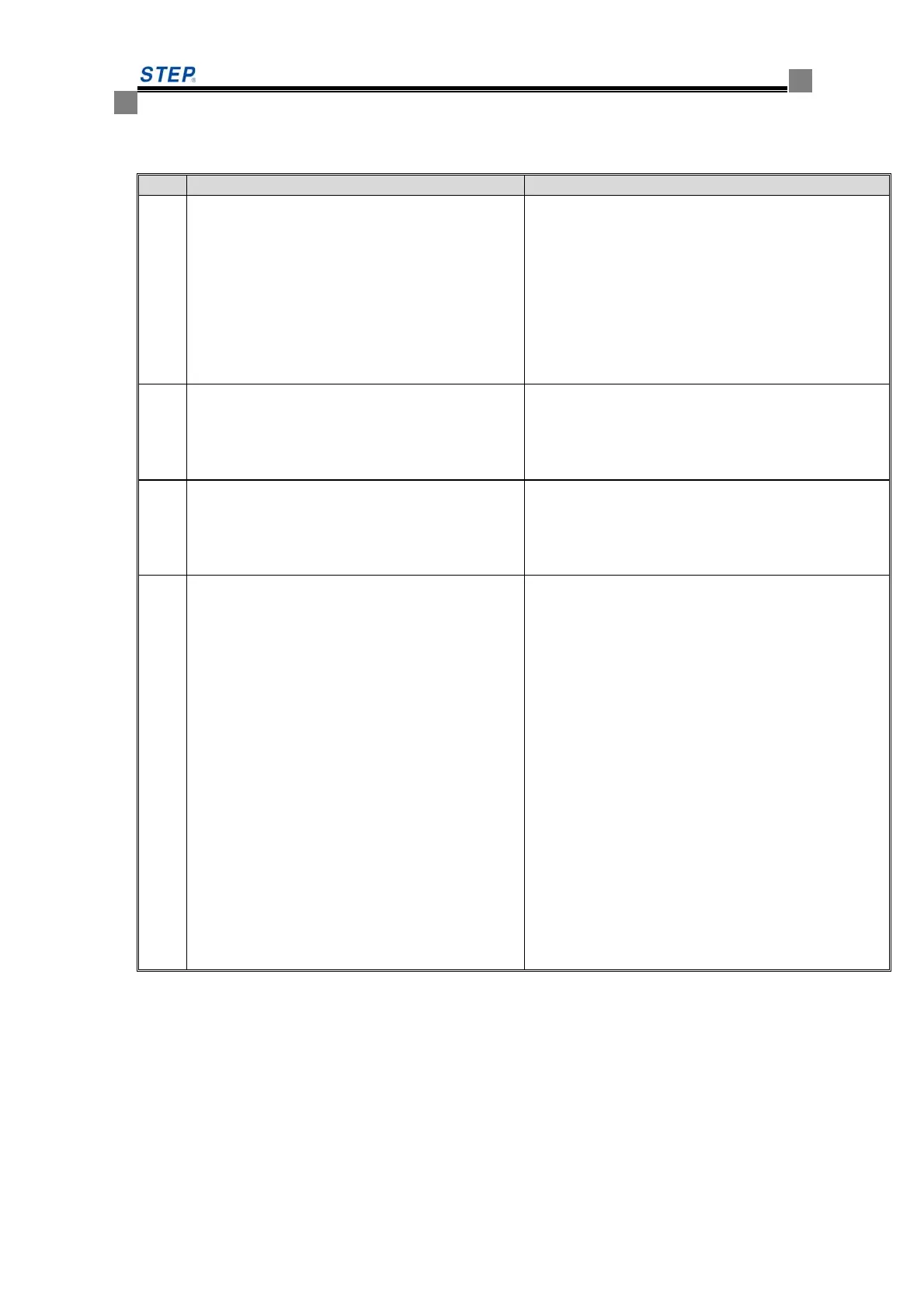

A2 Requirements on Cable Laying

A2.1 Requirement on Cable Laying

As shown by figure A2.1(a): To prevent mutual coupling of interferences, control signal cable

must be laid separately with supply cable and motor cable and be spaced as far as practicable. as

shown by figure A2.1(b): where the control signal cable has to cross over supply cable or motor

cable, they must be perpendicular with each.

Loading...

Loading...