Instruction Manual

for

AS380 Series Elevator Integrated Drive Controller

220

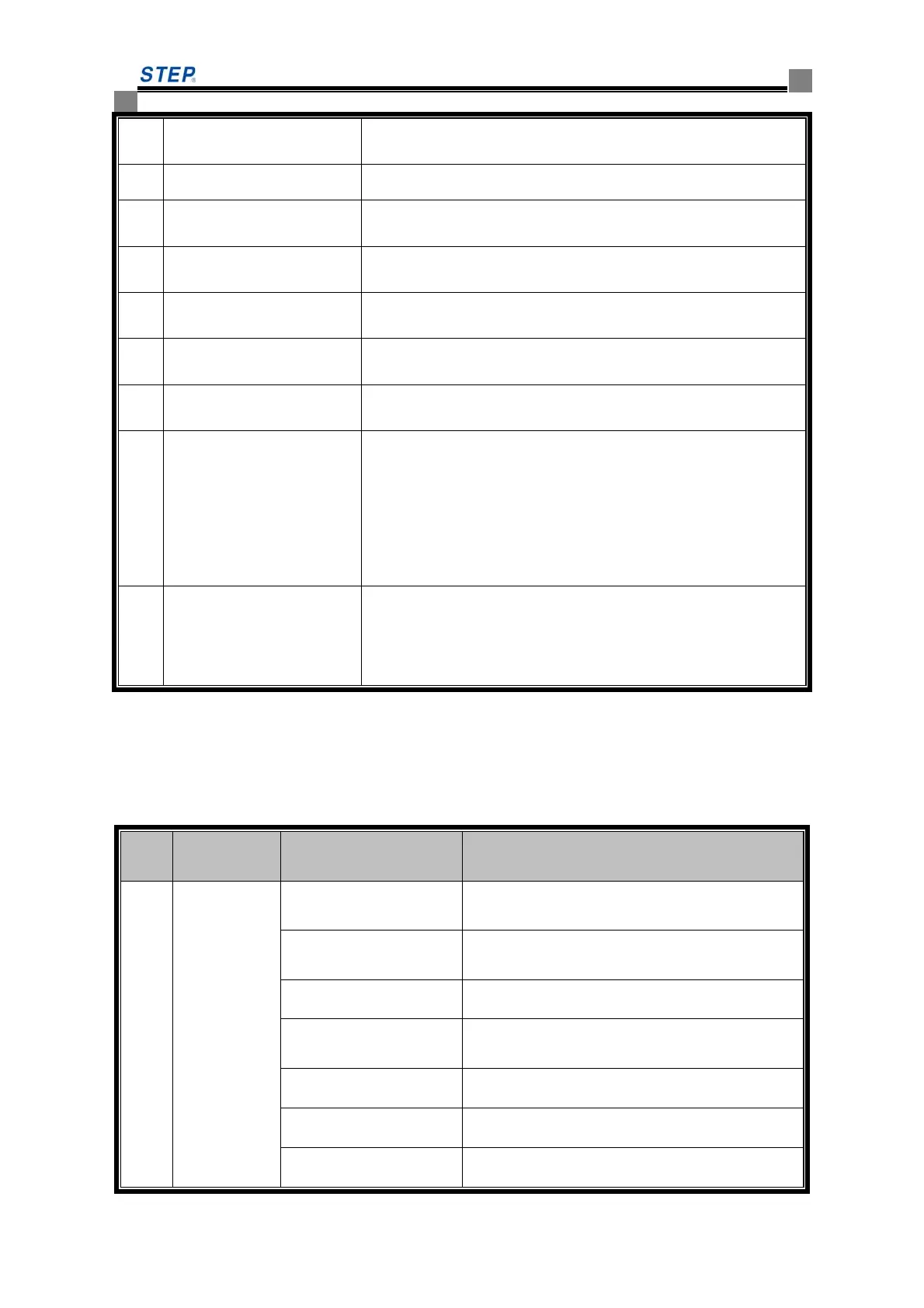

49

Communication failure

Exceptional communications in drive part and control part

50

Parameter error

Parameter read error

54

Inconsistent lock failure

When the door opens, the hall door lock has inconsistent pressure detection

point with the door lock

60

Base closure failure

In operation, the output contactor contact is detected disconnected, turn off

the output of the AIO and report Failure 60

61

Signal start failure

After the brake is opened, no zero servo terminal signal is received returning

from the drive part

62

No speed output

After start, the elevator maintains the speed at 0, and the elevator does not

move

67

RTC error Main board hardware error

68

The combination of the length of

the self study leveling spile and

the distance with the leveling

switch does not meet the

requirements

1) The leveling spile is too long or too short. Algorithm: (length of the

leveling spile + leveling switch space) / 2 less than 100mm or greater

than 900mm.

2) The leveling area is too long or too short. Algorithm: (length of the

leveling spile - leveling switch space) / 2 less than 10mm or greater

than 100mm

69

The inconsistency of the number

of self study spiles and the total

story number of the elevator

with the level bias

The number of spiles installed = Designed total story number(F11) - Offset

floor (F10). However, the total number of spiles installed is different from

the calculation value.

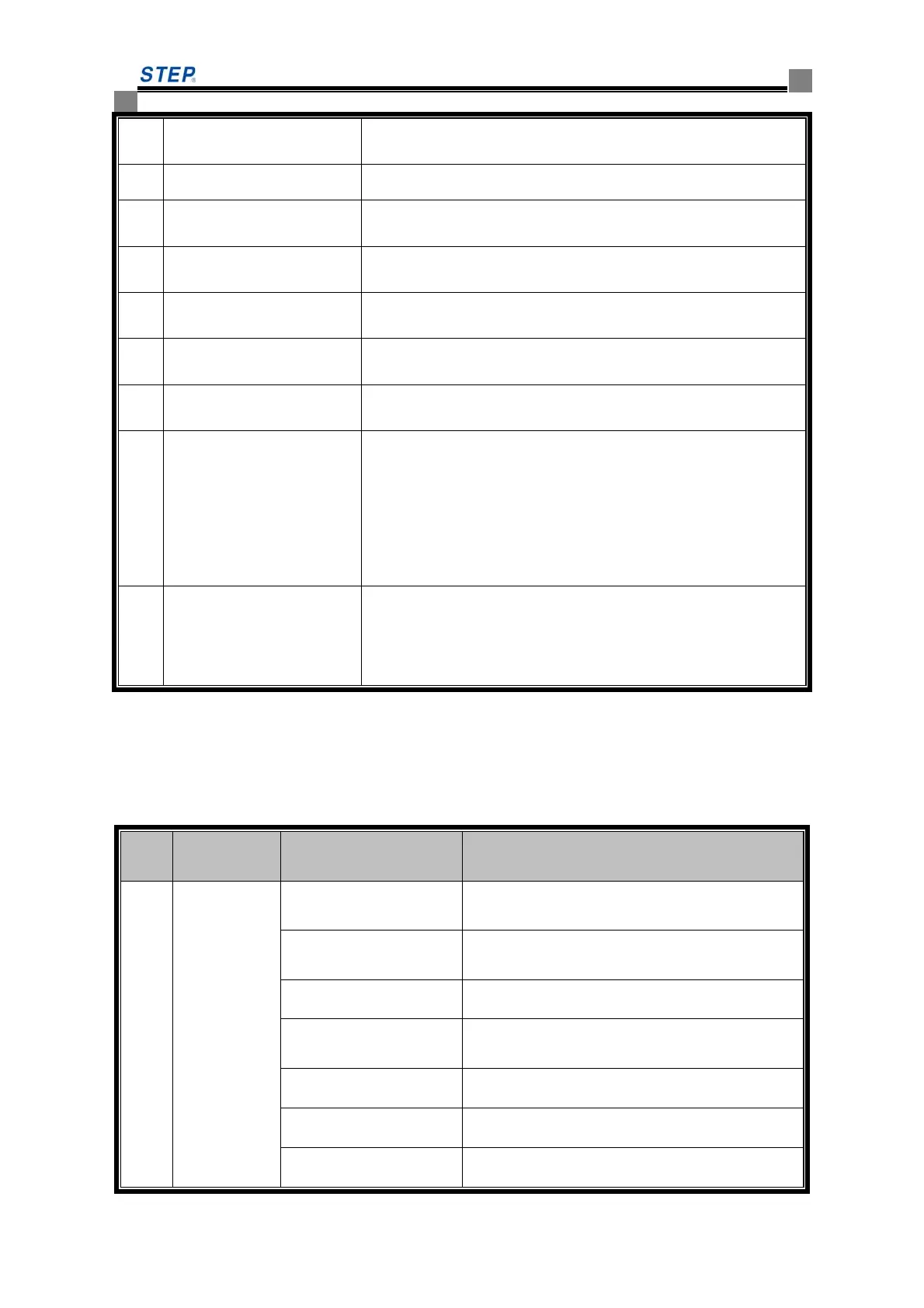

9.2 fault analysis of Integrated drive system

The fault code and analysis of drive system of AS 380 series elevator integrated drive controller is

shown in table 9.2

Table 9.2 drive system fault code table

Code

Fault

Description

Possible Cause Solution

71

Module

protection again

st over-current

DC terminal with

excessive voltage

Check power supply and high inertia loads. Rapid stop

without dynamic braking

short circuit at periphery Check whether the motor and the output wiring are short

circuit, whether earthing is short circuit

Open phase in output Check the motor and output wiring for loose

Encoder fault Check whether the encoder is damaged or the wiring is

correct

Encoder wrong phase Check motor phase

Motor wrong phase Check motor phase

Phase angle self-study Do self-study of phase angle again

Loading...

Loading...