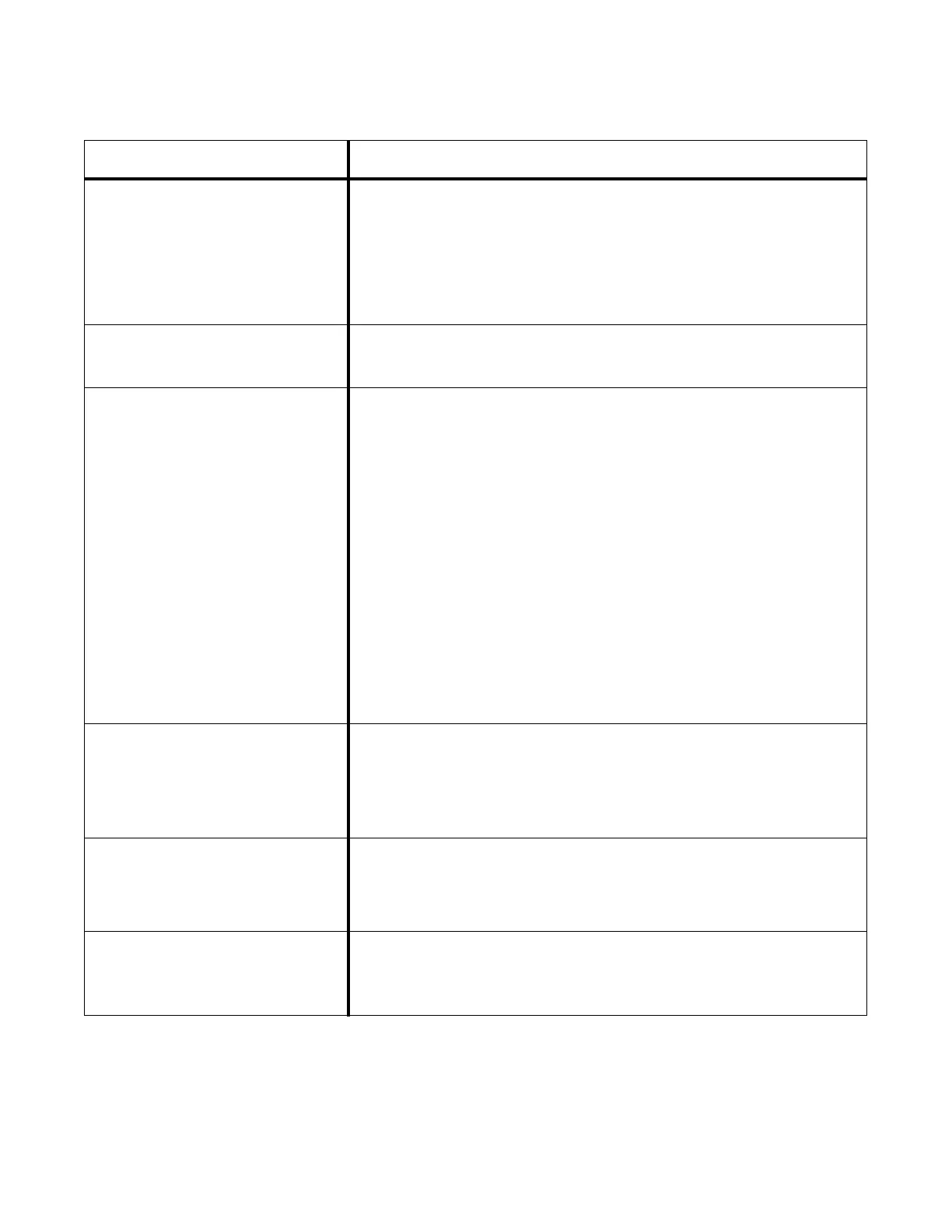

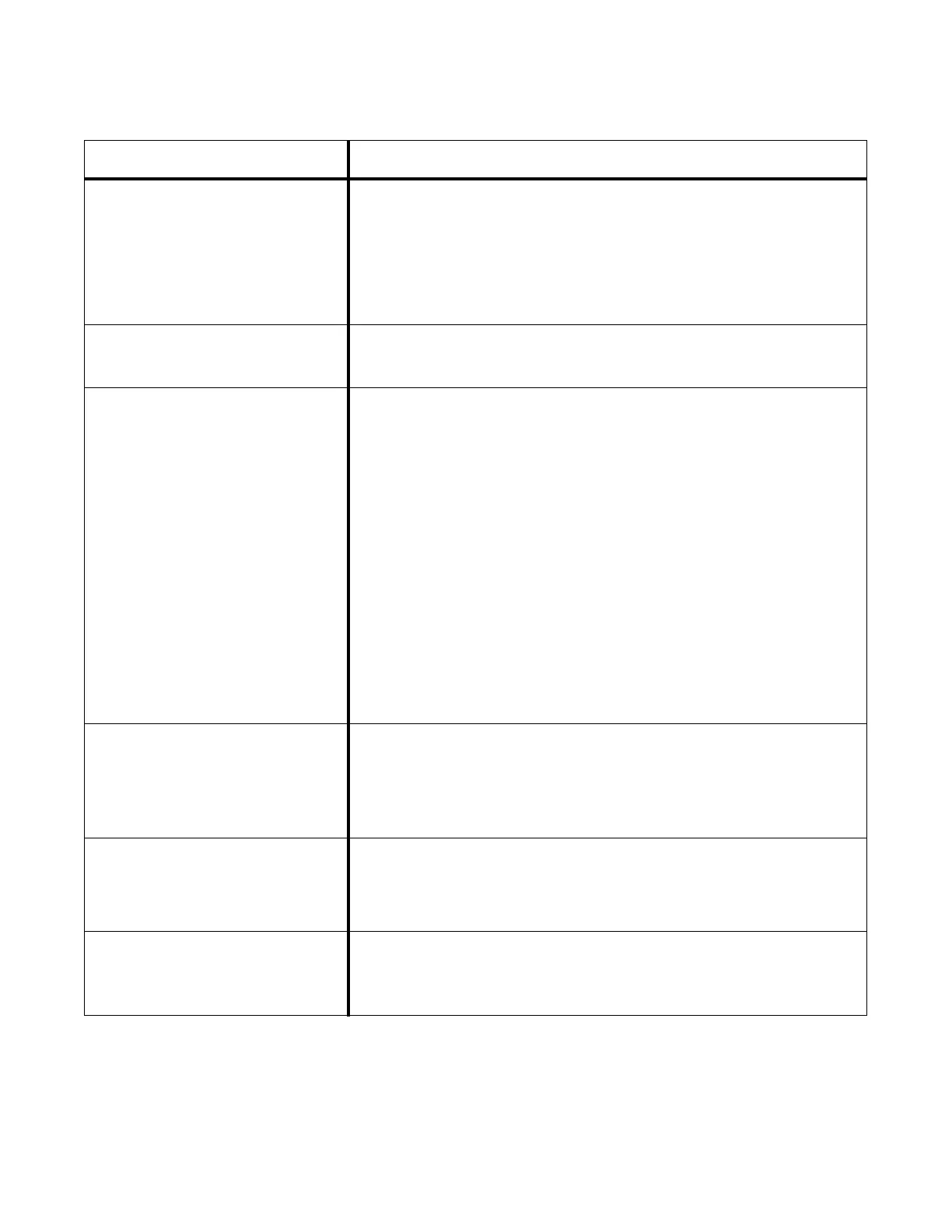

7-3

Troubleshooting Operator Manual 920509-645

7. Vapor escaping under door(s). 1. Exhaust dampered too much – call STERIS.*

2. Optional exhaust system OFF – verify operation of applicable

option.

3. Optional exhaust fan rotating in wrong direction – call STERIS.*

4. Building vent connections inadequate – call STERIS.*

8. Pump starts before appropriate

sump water level is reached.

1. Verify operation of water level – clean as necessary.

2. If condition reoccurs, call STERIS.*

9. Pump runs with insufficient or

no pump pressure.

1. Suction pump strainer clogged – clean strainer.

2. Water level malfunctions – verify operation of water level. Clean or

replace as necessary.

3. Water temperature in excess of 195°F (91°C) – lower temperature

set point.

4. Self-cleaning screen clogged – remove debris from screen.

5. Loose hose connection on pump suction strainer – call STERIS.*

6. Pump rotating in wrong direction – call STERIS.*

7. Foam in chamber – rinse chamber with cold water and decrease

detergent injection rate; call STERIS.*

8. Compression fitting on pump RTD, located in suction pick-up pipe,

is leaking air – call STERIS.*

10. Carriage drive system not

operating properly.

1. Drive clutch loose – call STERIS.*

2. Spray headers hitting sealing strips covering vertical panel joints –

call STERIS.

3. Drive cable loose or broken – call STERIS.*

11. Washer operation stops during

cycle.

1. Loose connection in control wiring – call STERIS.*

2. Electrical component failure (e.g. motor starter) – call STERIS.*

3. Control fuse failed – call STERIS.*

12. Foam in chamber. 1. Detergent is foaming – use recommended products.

2. Too much detergent injected during Wash phase – verify injection

rate; call STERIS.*

* Service Charges may be incurred. Consult your warranty for details.

Table 7-1. Troubleshooting Chart (Cont’d)

PROBLEM POSSIBLE CAUSE AND CORRECTION

Loading...

Loading...