INSTALLATION

Preparation

Pipe assembly for undersink appliances

You will need the undersink installation set if you make the water

connections (G

3

/s A) at the top of the appliance.

Pipe assembly for offset installation

Use this pipe assembly if you intend to offset the appliance by up

to 90 mm downwards from the water connection.

Pipe assembly for replacing a gas water heater

You will need this pipe assembly set if the existing installation

has gas water heater connections (cold water connection on the

left-hand side, DHW connection on the right-hand side).

Pipe assembly for DHB water plug-in couplings

Use the water plug-in couplings if the existing installation contains

water plug-in connections from a DHB water heater.

Load shedding relay (LR 1-A)

The load shedding relay for installation in the distribution board

provides priority control for the instantaneous water heater when

other appliances, such as electric storage heaters, are being op¬

erated simultaneously.

9. Preparation

9.1 Installation location

©

Material losses

Install the appliance in a room free from the risk of frost.

► Always install the appliance vertically and near the draw-off

point. For horizontal installation, see chapter "Alternative in¬

stallation methods / Horizontal installation of the appliance".

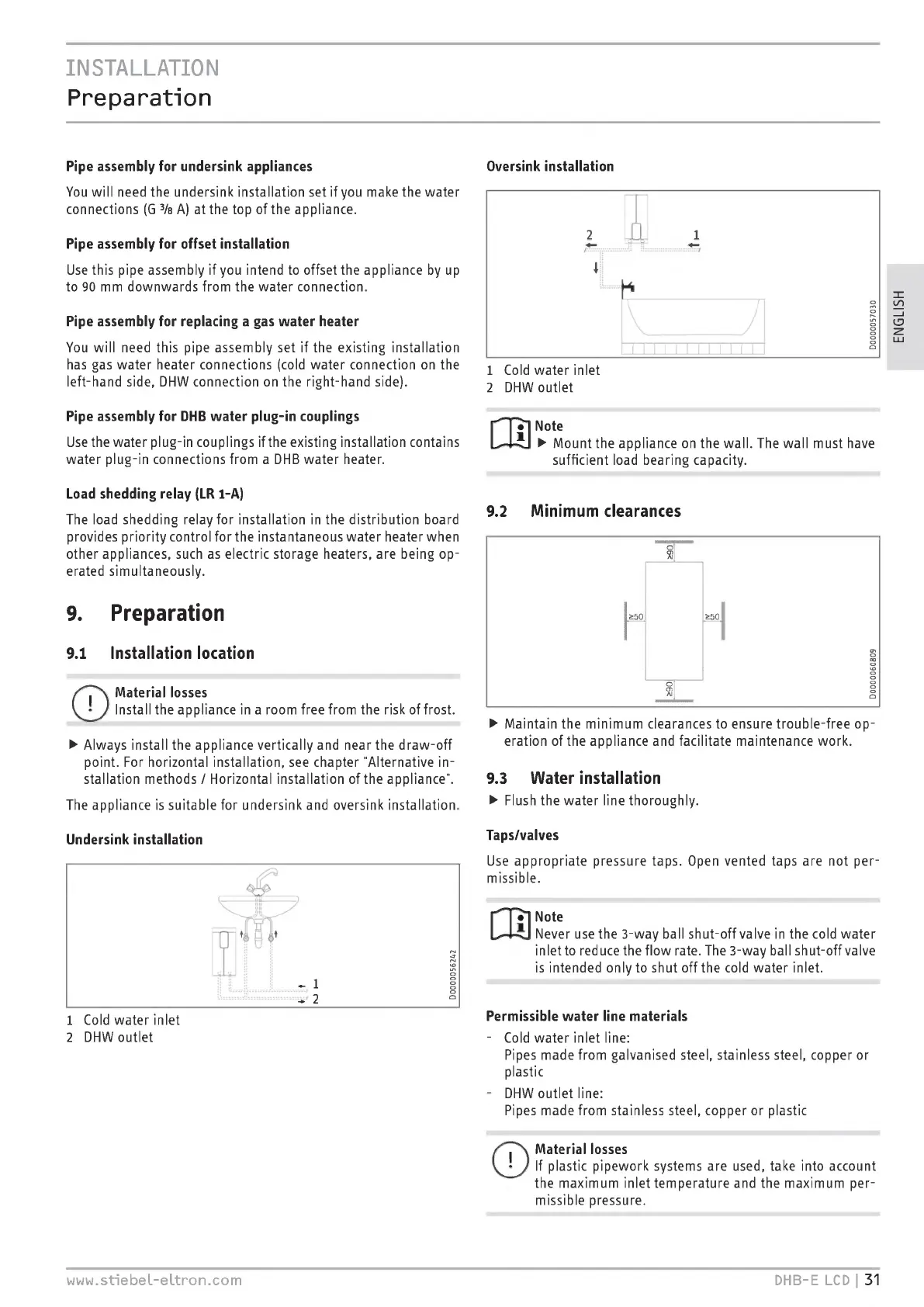

The appliance is suitable for undersink and oversink installation.

Undersink installation

2 DHW outlet

2 DHW outlet

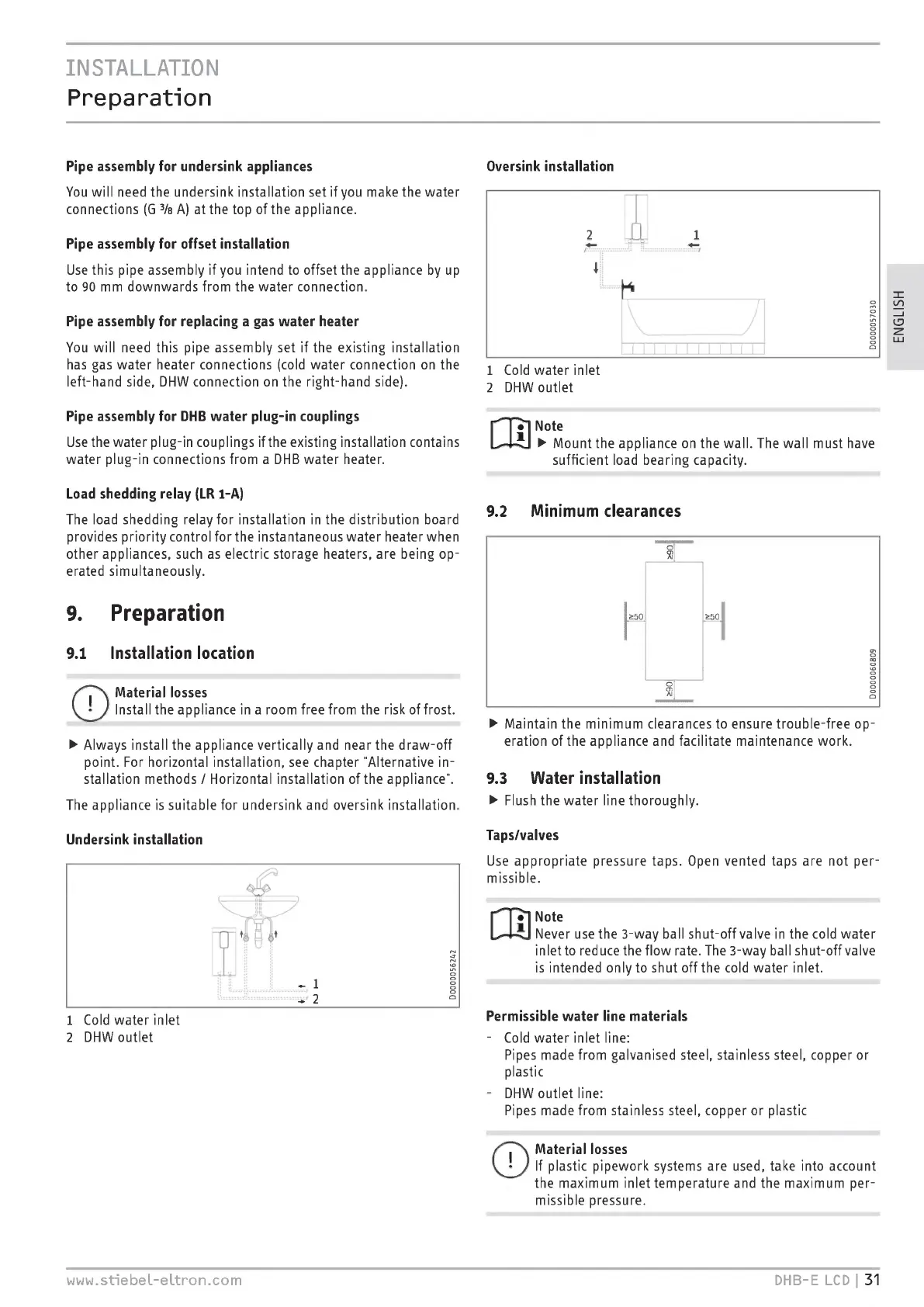

Note

► Mount the appliance on the wall. The wall must have

sufficient load bearing capacity.

9.2 Minimum clearances

► Maintain the minimum clearances to ensure trouble-free op

eration of the appliance and facilitate maintenance work.

9.3 Water installation

► Flush the water line thoroughly.

Taps/valves

Use appropriate pressure taps. Open vented taps are not per¬

missible.

Note

Never use the 3-way ball shut-off valve in the cold water

inietto

reduce the flow rate. The 3-way ball shut-off valve

is intended only to shut off the cold water inlet.

Permissible water line materials

- Cold water inlet line:

Pipes made from galvanised steel, stainless steel, copper or

plastic

- DHW outlet line:

Pipes made from stainless steel, copper or plastic

©

Material losses

If plastic pipework systems are used, take into account

the maximum inlet temperature and the maximum per¬

missible pressure.

www.stiebel-eltron.com

DHB-E LCD I 31

ENGLISH

Loading...

Loading...