OPERATION & MAINTENANCE MANUAL SWE18UF

100

1) Park machine on the level ground, lower the bucket to the ground and place its plane surface on the

ground. Ensure the bucket won’t roll after pins are removed.

2) Remove the orientation pin at the clip spring exterior and take out orientation pin.

3) Remove bucket pin A and B, separate arm and bucket.

4) Clean orientation pin, pin and holes, daub sufficient

lubricant to them.

5) Calibrate the arm and new bucket, ensure the bucket

will not to roll.

6) Fit pin A and B, and fit corresponding orientation pins

and new clip springs.

7) Adjust bucket connection clearance of pin A and B.

Guarantee the unilateral clearances between bucket and

connection rod, and between clearance bucket and arm

are from 0.25mm to 0.7mm, the clearance between pin

and bucket should be as little as possible. Use adjusting

gasket to adjust the middle clearance.(use the same

amount of gasket at both sides)

8) Grease pin A and B.

Lubrication of control lever

Add some lubricant to the control lever and pedal if they

cannot move smoothly.

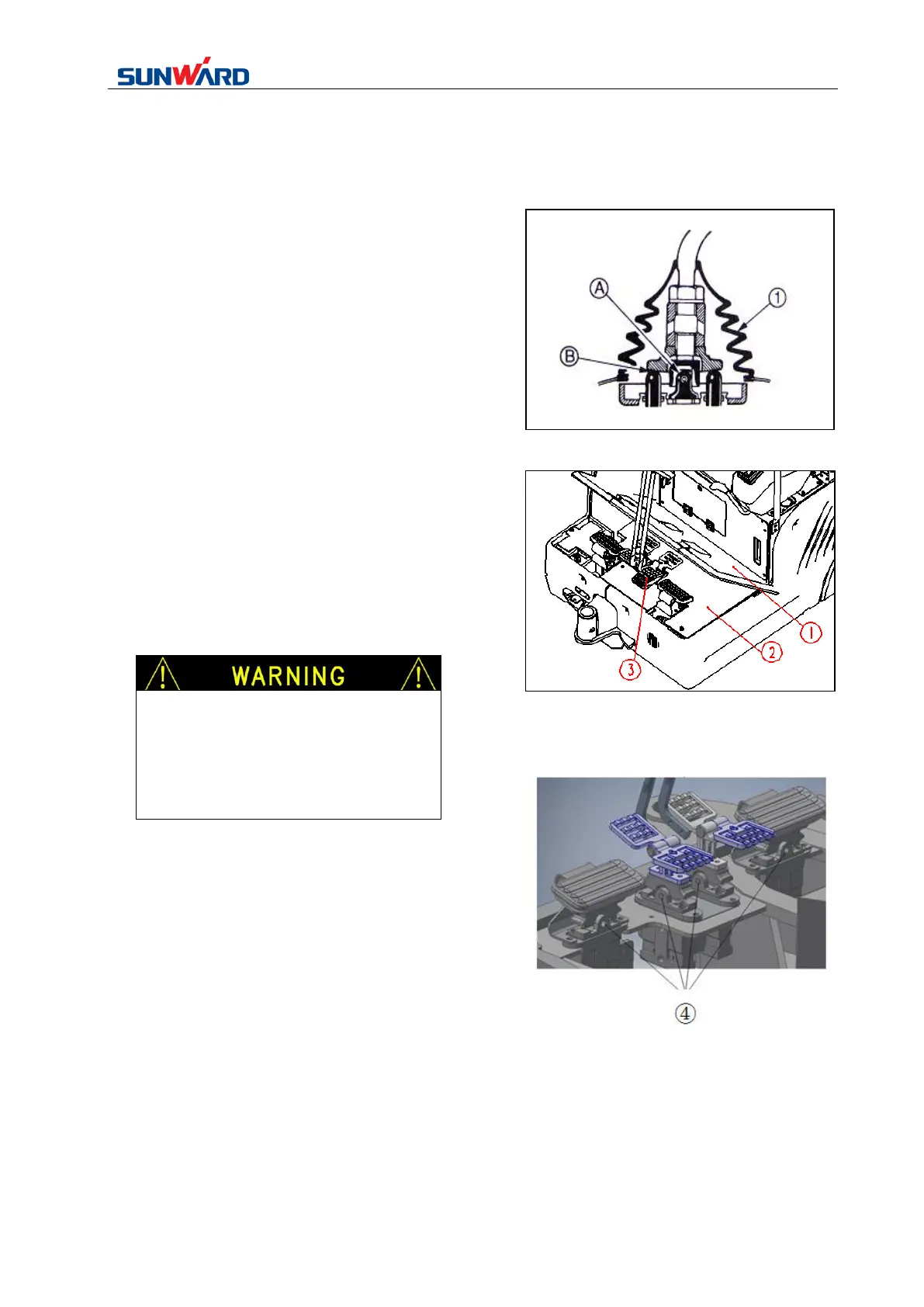

A. Control lever

1) Disassemble the low part of the rubber dustproof

cover of the operation lever, turn over it upward.

2) Clean the aging lubricant and add new lubricant.

3) Reinstall the rubber dustproof of control lever.

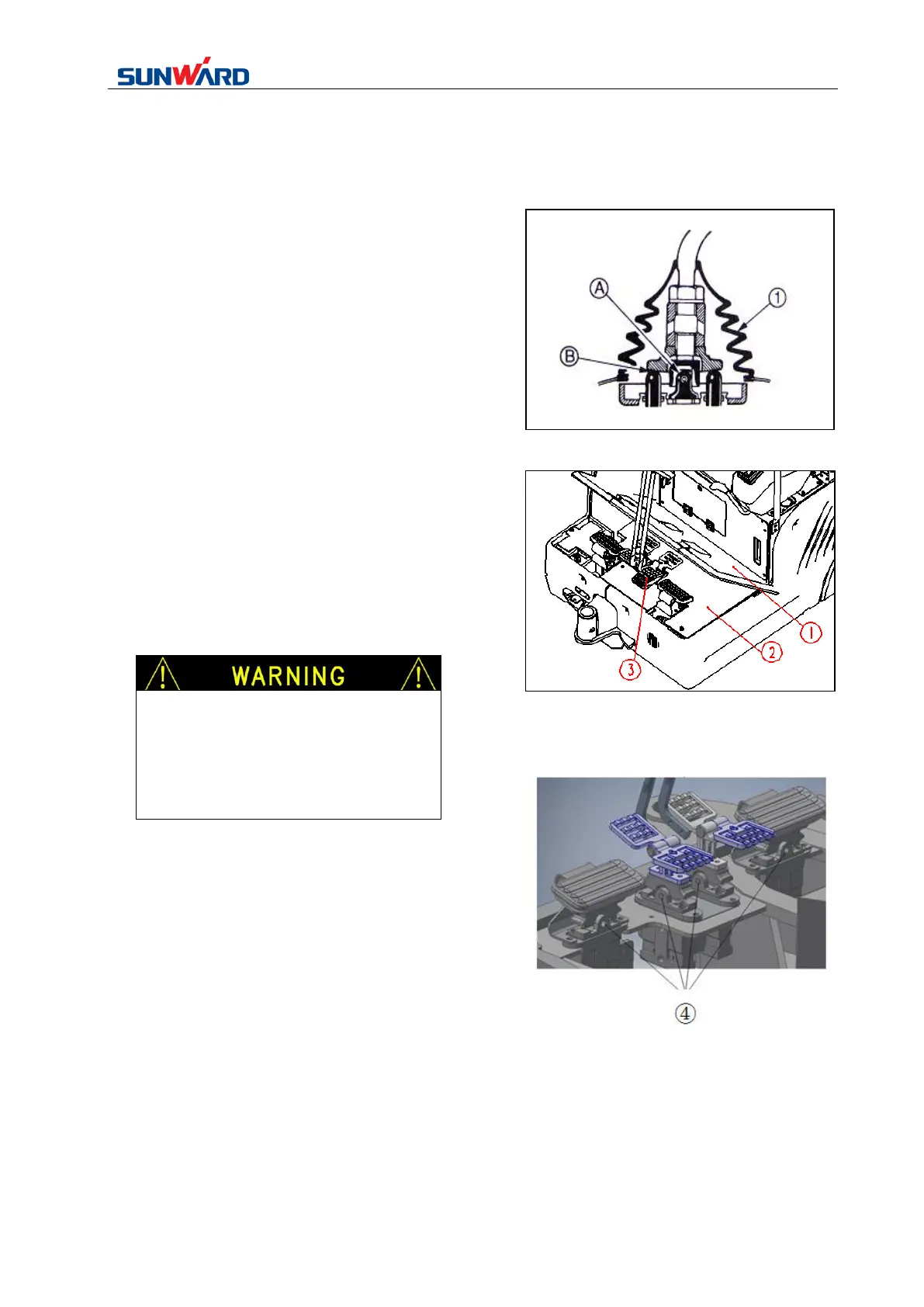

B. Connecting rod mechanism

1) Remove rubber mat ①.

2) Loosen the bolt, disassemble cover ②.

3) Disassemble the bottom part of dust cover ③ and turn it over.

To prevent injury caused by flying

off metal scrap when beating the

connection rod in or out, wear

goggles, safety glasses or other

safety instrument.

FIG.100

FIG.98

Never start engine when the

hydraulic oil tank is empty.

Loading...

Loading...