OPERATION & MAINTENANCE MANUAL SWE18UF

124

9.3.3 Operation Key Points of Hydraulic Breaker

(1) Cap the pipe end of arm and dismantle the hammer breaker

when not use.

(2) Install plugs for hose ends to prevent dirt.

(3) Store some spare caps and plugs for necessary use.

(4) Avoid dirt entering when changing the installation of bucket to

hammer breaker.

(5) After connection, check seal for oil leakage and bolts of tube

clamp for slack.

Before installing the hammer breaker to the arm, the operation manual of the excavator and the hammer

breaker should be read carefully. In addition, confirm or check as

required.

(1) Confirm and check as requirements before operation every

day.

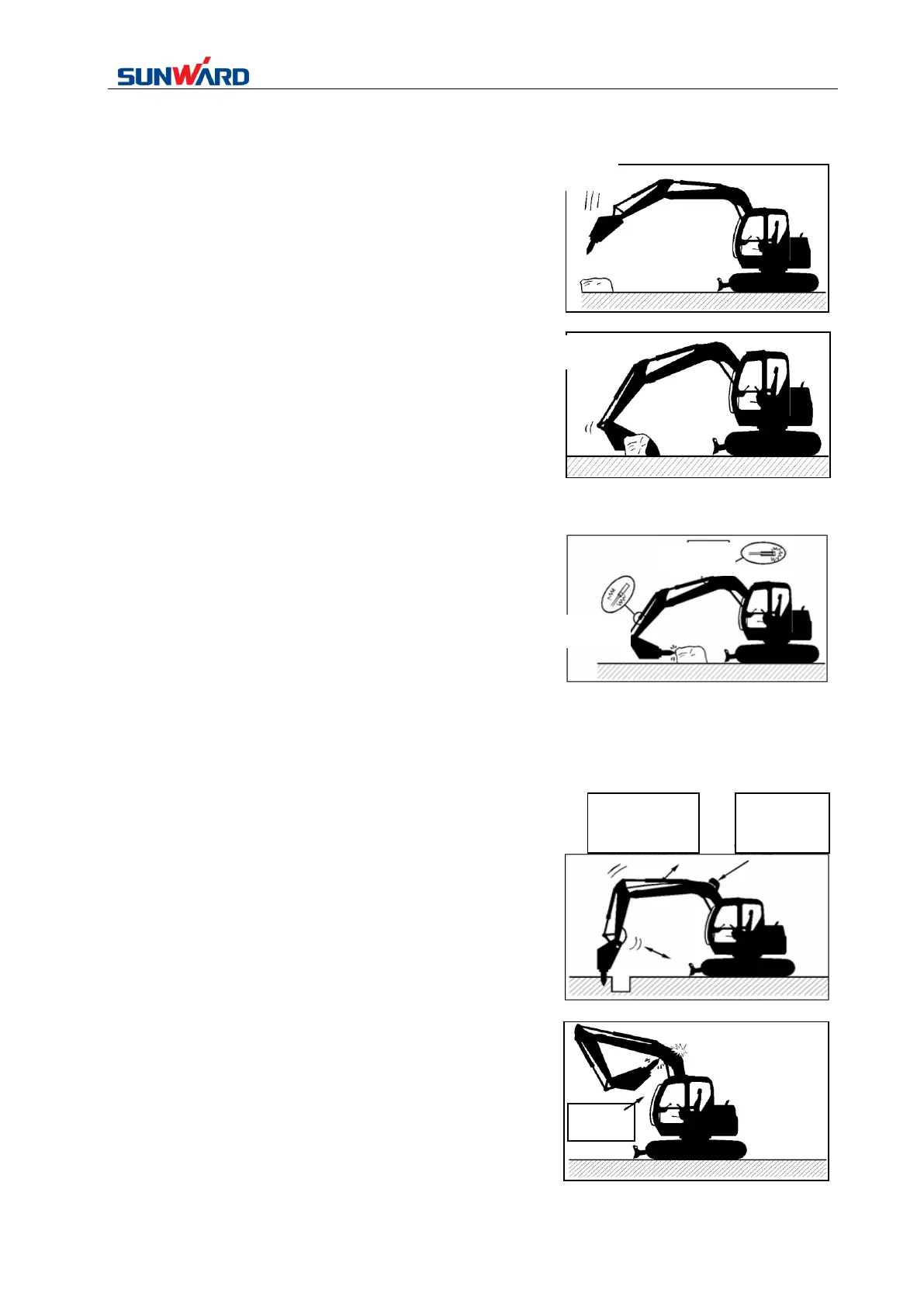

(2) Operate the excavator slowly. Because the hammer breaker is

heavier than the bucket, that is the reason of the descending stability of the excavator. Thus, it should be

supported by mouldboard and the operation should be done in the front.

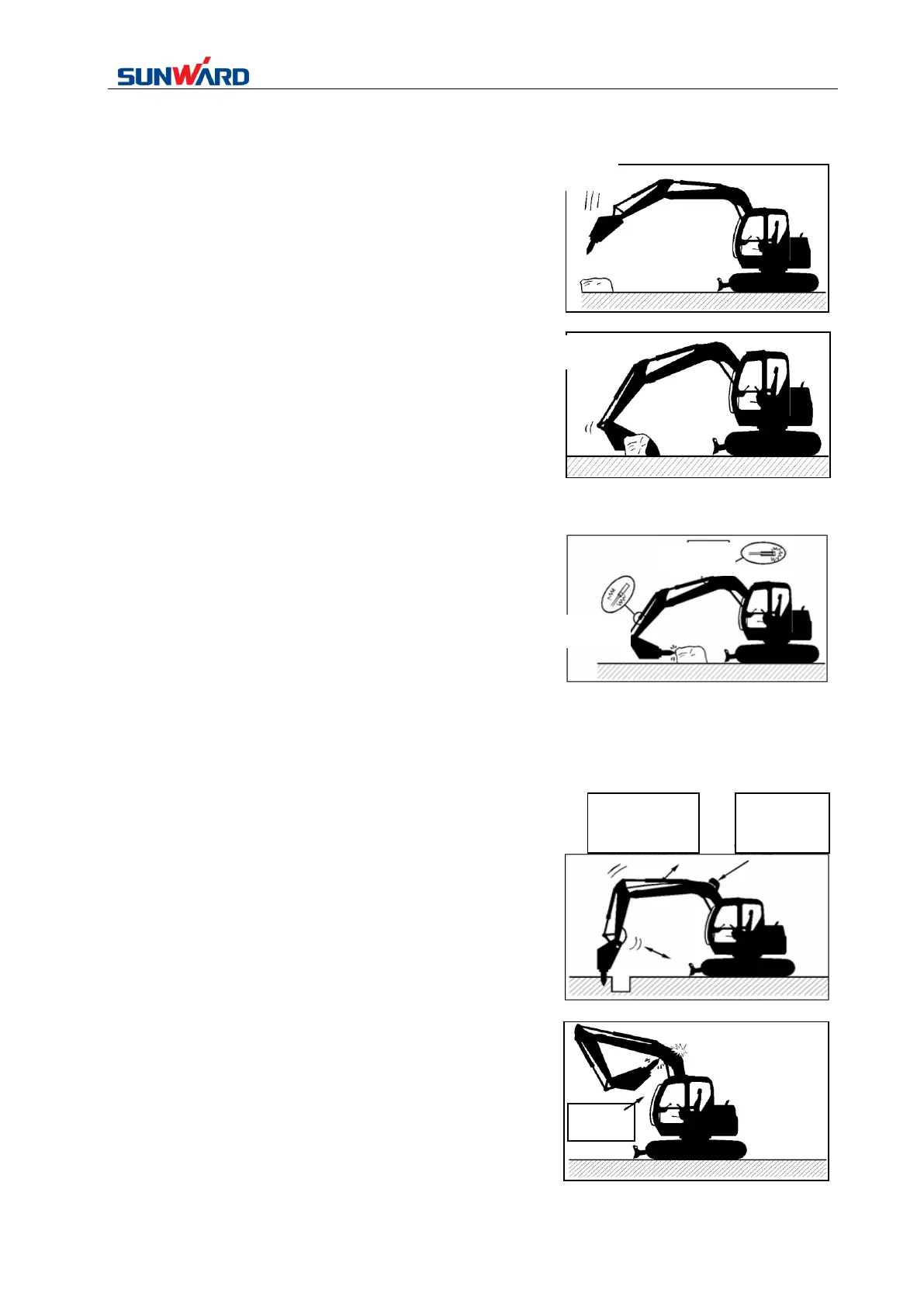

(3) Avoid using the hammer breaker for striking. Never use boom or

arm to break objects. If not, the excavator may be damaged.

(4) Don’t move objects with the hammer breaker, if failure to do

so, the excavator may be damaged.

(5) Don’t operate the hammer breaker when the hydraulic piston

rod is fully retracted or extended to avoid the damage of hydraulic

cylinder or the excavator.

(6) If there’s abnormal jump of hydraulic hoses of the hammer

breaker, stop the operation immediately. That’s caused by the

damaged accumulator, of which the pressure change of the hammer

breaker. More seriously, the hammer breaker and the excavator

may be damaged too.

Loading...

Loading...