OPERATION & MAINTENANCE MANUAL SWE18UF

39

walk under the machine.

This lifting procedure applies to machine with

standard specifications.

To get the lifting methods information for the

machines equipped with other attachments or

optional devices, please contact SUNWARD or

our distributor.

Machine lifting procedure

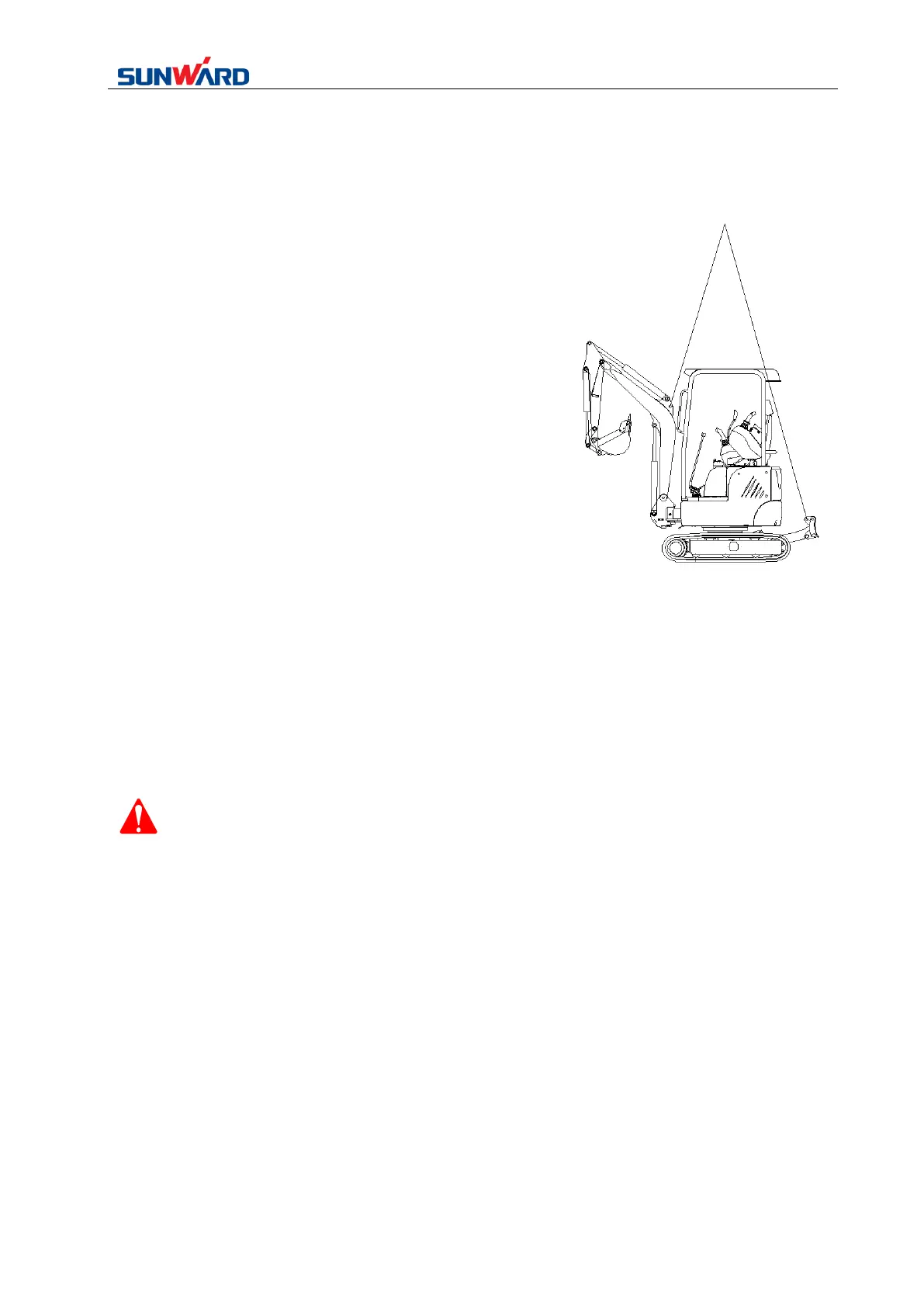

(1) Swing upper-structure to one side of the drive sprocket, lift

the boom and retract arm and bucket complete, as shown in

right figure.

(2) Swing work attachment to the right side and retract swing

cylinder fully; Raise dozer blade with the operating control

joystick and the dozer cylinder is retracted completely, as

shown in right figure.

(3) Shut down the engine, take out the key and lock cab’s door

and windows;

(4) Use steel ropes and support rods with enough length and

twine the machine with protective material to avoid damage;

(5) Reeve the steel rope through four pedals on front, rear, left

and right, and then fasten firmly;

(6) Adjust steel rope to make the lifting angle is not over than

40°;

(7) Lift the machine slowly, and always keep the machine in

level position. If not level, the steel rope should be adjusted

again.

2.2 STORAGE

Note

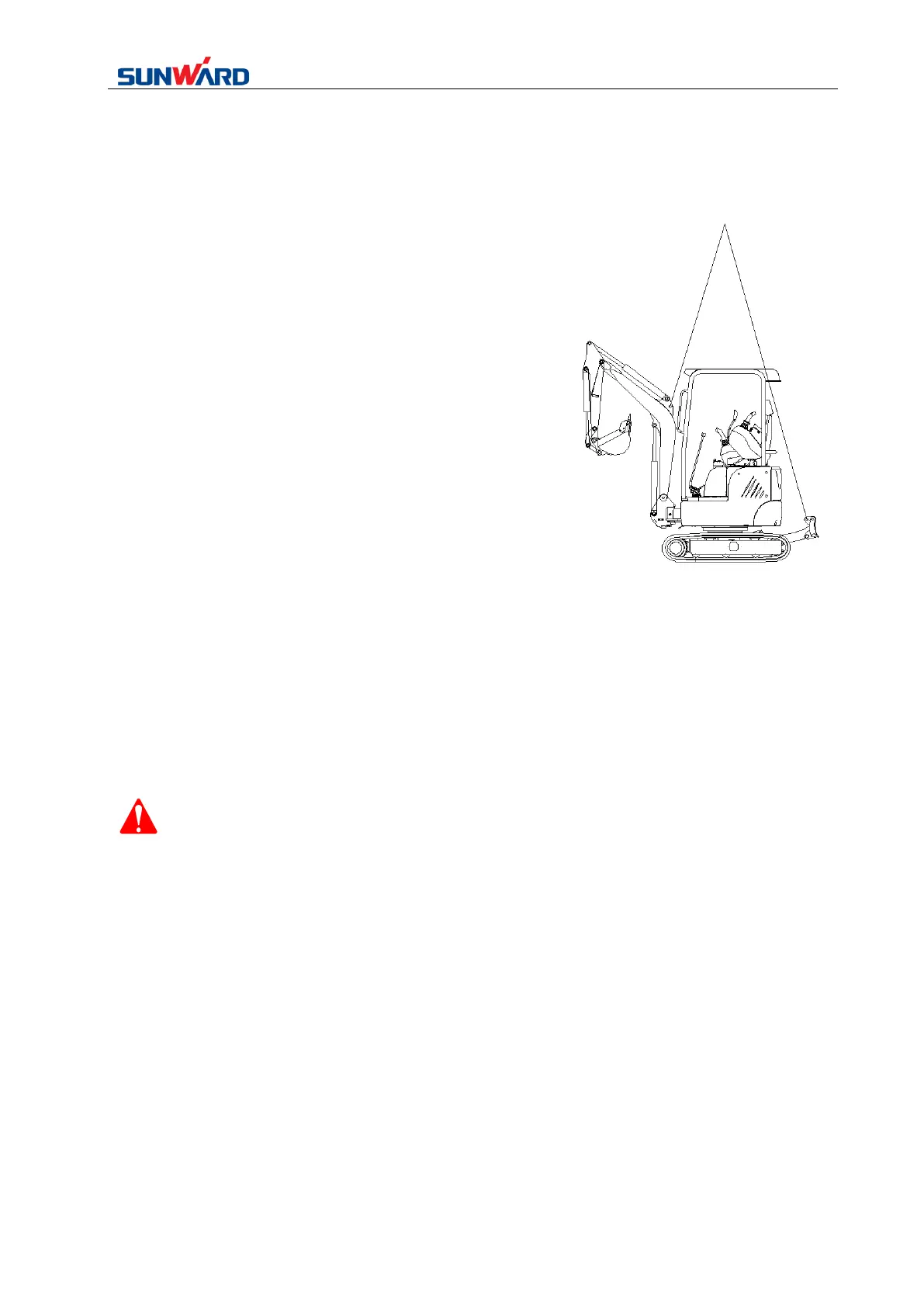

To protect the hydraulic cylinder piston rod

while in storage, keep the work equipment in the

fig shown at right. (This prevents rust from

developing on the piston rod).

2.2.1 Before Storage

Clean and wash all surface and exposed parts.

Apply grease to all lubricating parts until fresh grease

spills out.

Change engine oil.

Apply grease to exposed parts on piston rod.

Top up fuel tank with fuel.

Loading...

Loading...