OPERATION & MAINTENANCE MANUAL SWE18UF

94

5.2.6 Air Filter

2.Air filter and

connecting pipes

between engines

Replace immediately when crack or leakage is detected

1) Park excavator on level ground.

2) Lower bucket to ground

3) Idle the engine for 5 minutes.

4) Stop engine, and take out key switch.

5) Pull pilot control lever to lock position.

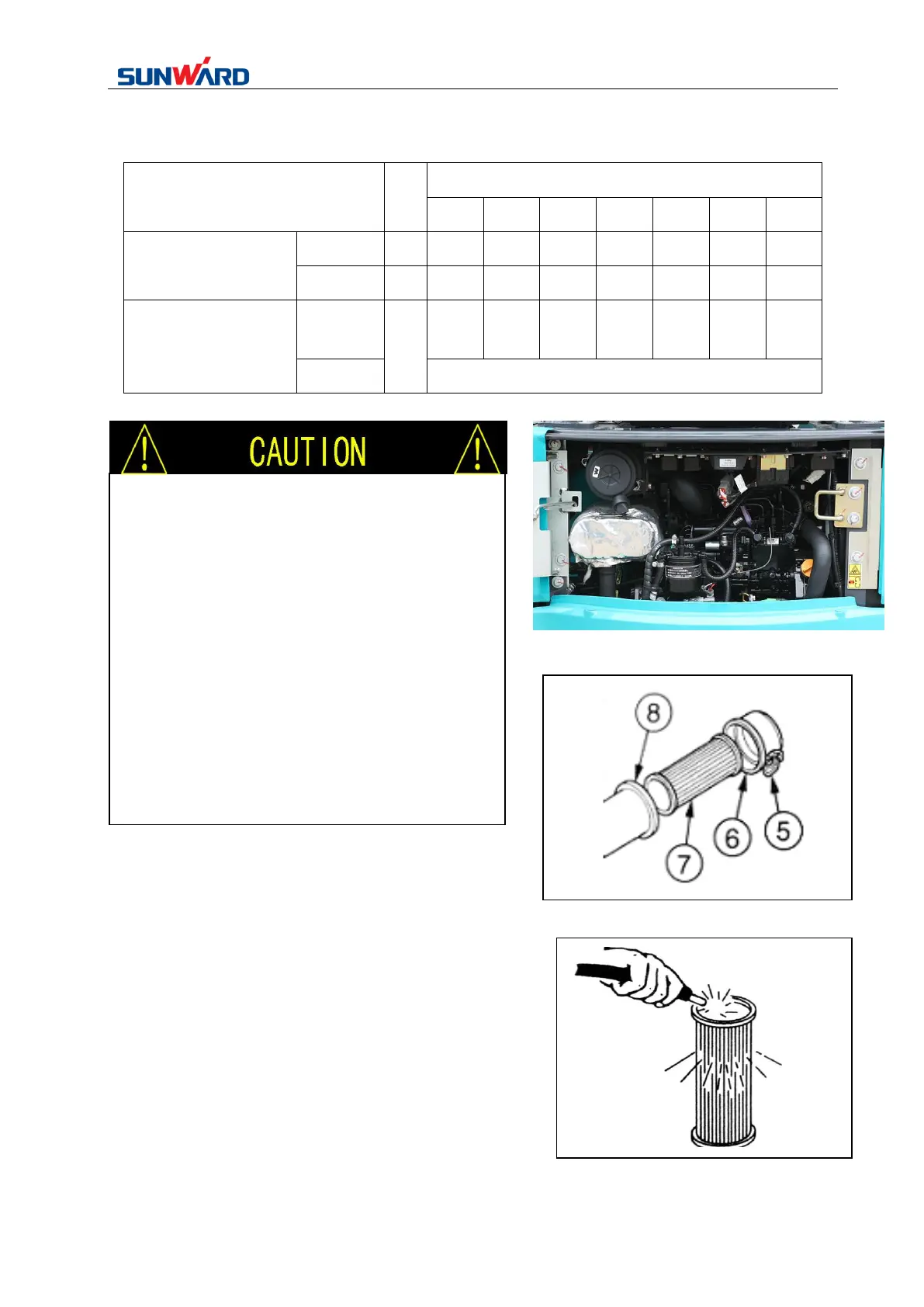

6) Open engine cover.

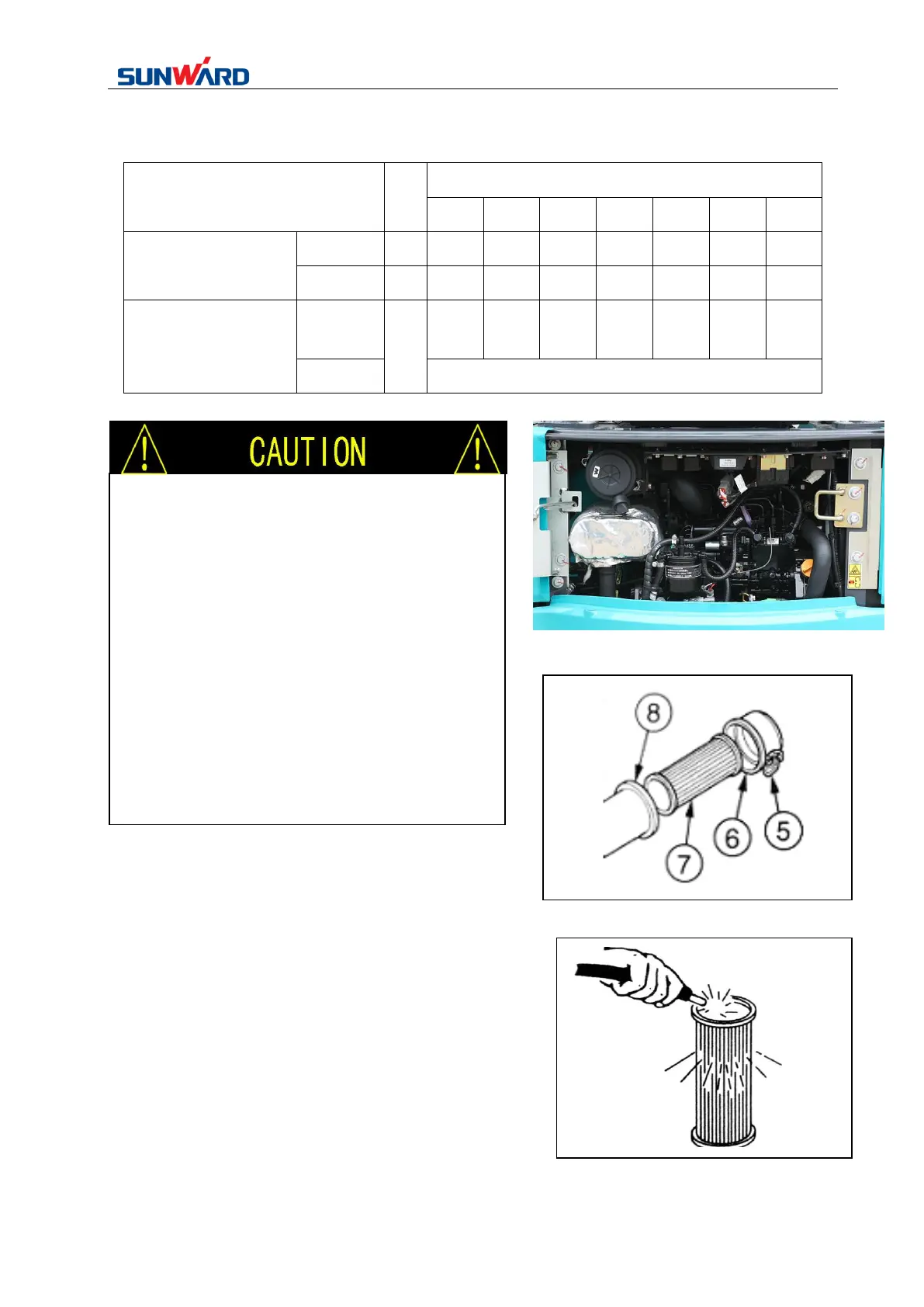

7) Release the lock catch ⑤ and take out the dust collection

cup ⑥.

8) Clean the interior of the dust collection cup ⑥

9) Take out the filter element ⑦.

10) Cover the back ⑧ of the casing of the air filter with cloth

Only clean air filter at scheduled time to

prevent dust entering engine.

Also check airproof and fixation termly of

elastic joint between engine and air filter.

Because the engine, muffler, radiator, hydraulic

oil pipe, glide components and many other parts

of the machine may still hot, touching may cause

scald.

Shut off engine and cool the machine down

before inspection and maintenance.

Wear proper protective equipment when

operating compressed air, such as blinkers and

light filter mask, metal scraps or other objects

may cause damage to human body.

FIG.100

FIG.98

Never start engine when the hydraulic oil tank

is empty.

Loading...

Loading...