M A I N T E NAN C E

OP MA6-8/BA6-8 E Rev05 07-06 Maintenance 49

2

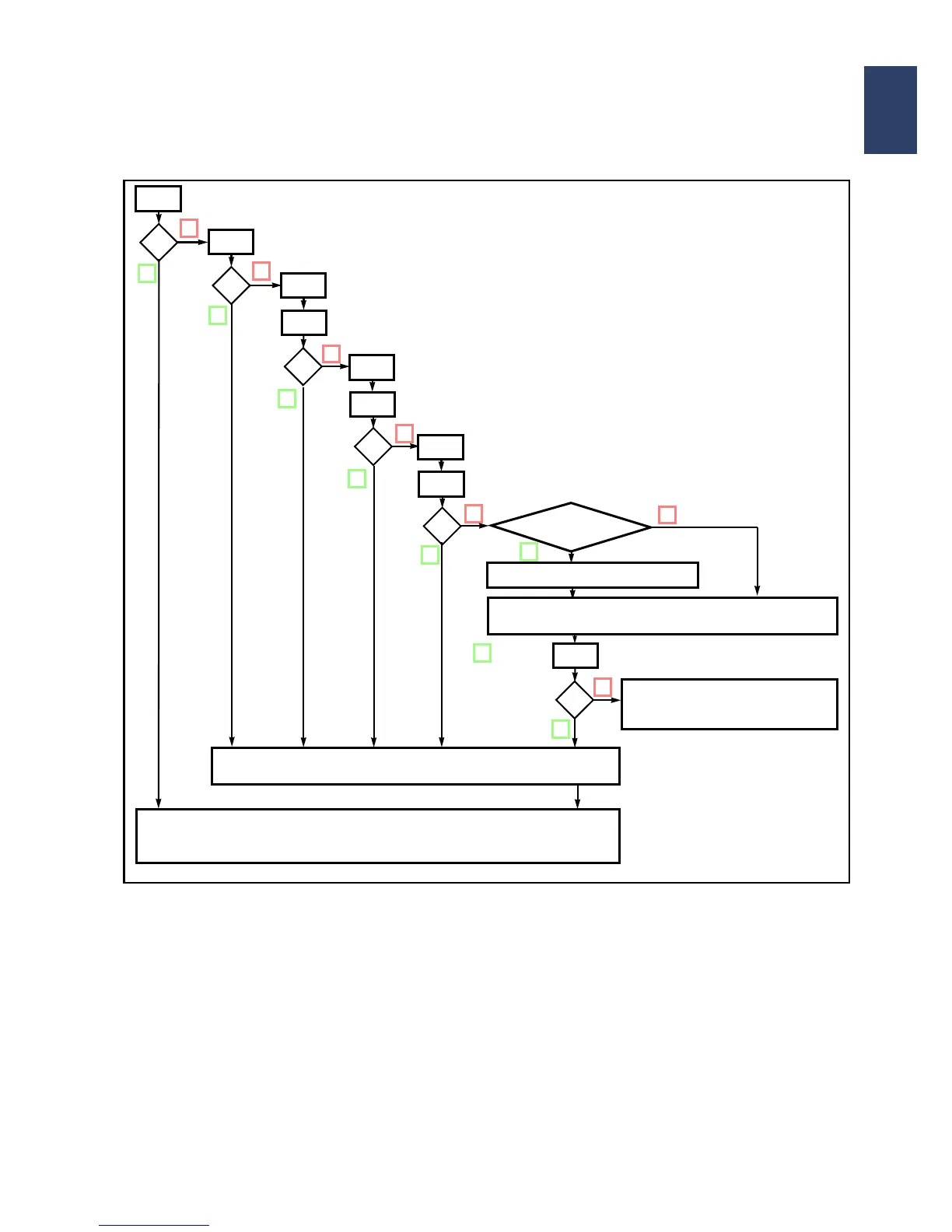

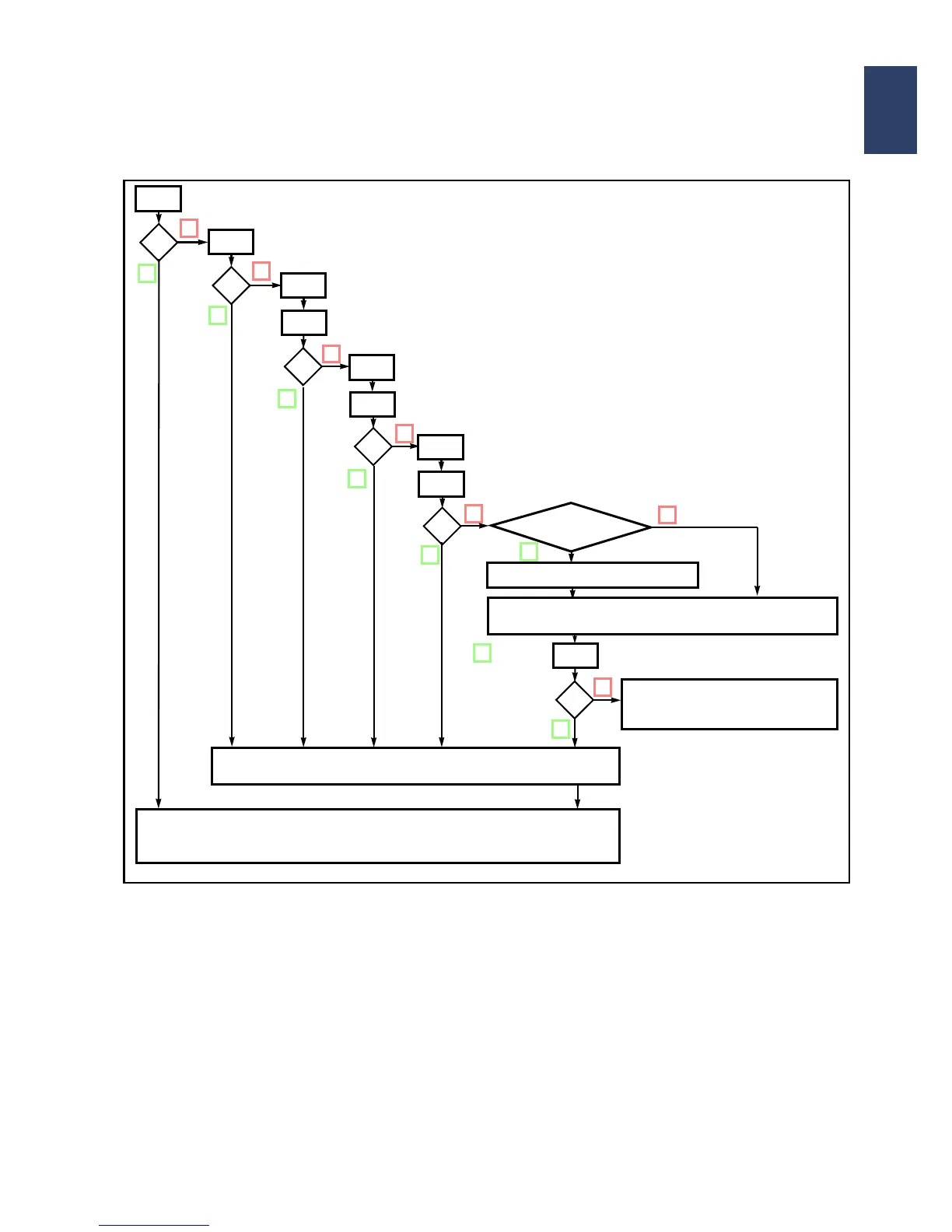

Legend to the cleaning procedure diagram:

N2 - blow off dust (or droplets) with nitrogen

y/n - check, if surface is clean (y=yes/clean;

n=no/no success)

DI - rinse with DI-water or submerge to DI-

water (as appropriate for the component.

Soap - rinse or submerge with detergent (1%) in

DI-water.

IPA - rinse or submerge with isopropanol alcohol

PE - Petroleum ether (special light benzine)

For extremely obstinate contaminations petroleum

ether can be used in addition to IPA.

If a treatment step has been nearly successful, but

one cannot be satisfied completely by the result, re

-

peat this step, prior to trying the next treatment step

or solvent type.

When a cleaning procedure proved to be successful

at an individual machine or production line, use al

-

ways the same procedure and solvent when the op-

tics of the identical machine needs cleaning again.

N

2

DI

Soap

n

?

?

n

DI

?

IPA

DI

?

n

n

Coated

Optics

Proceed exremely gently

Wipe carefully with soaked clean tissue (see text)

use the liquid, which proved most effective before

PE

DI

?

n

DI

?

n

Exchange component or

call for SUSS Service

N

2

- Blow completely dry with clean Nitrogen

Reinstall the optical component

y

y

y

y

y

y

y

y

n

(attend location and orientation)

Loading...

Loading...