M A I N T E NAN C E

OP MA6-8/BA6-8 E Rev05 07-06 Maintenance 45

2

2.4.3. N2-Control

Cooling of lamp sockets is adjusted by two pressure

valves 11/R5.X (X= 2 and 5), one for each lamp

socket (in LH1500). The pressure for the lower sock

-

et is continuously monitored by the pressure meter

11/C4.

• The adjustment of the N

2

pressure valves has to

be done following any part exchange in the cool

-

ing system.

• Only qualified service personnel is allowed to

perform the adjustment. For details see sections:

Working with the Mask Aligner in Chapter 1 and

Utilities in Chapter 2.

• The setting must be completed prior to starting a

lamp. Otherwise there is a risk of lamp explosion.

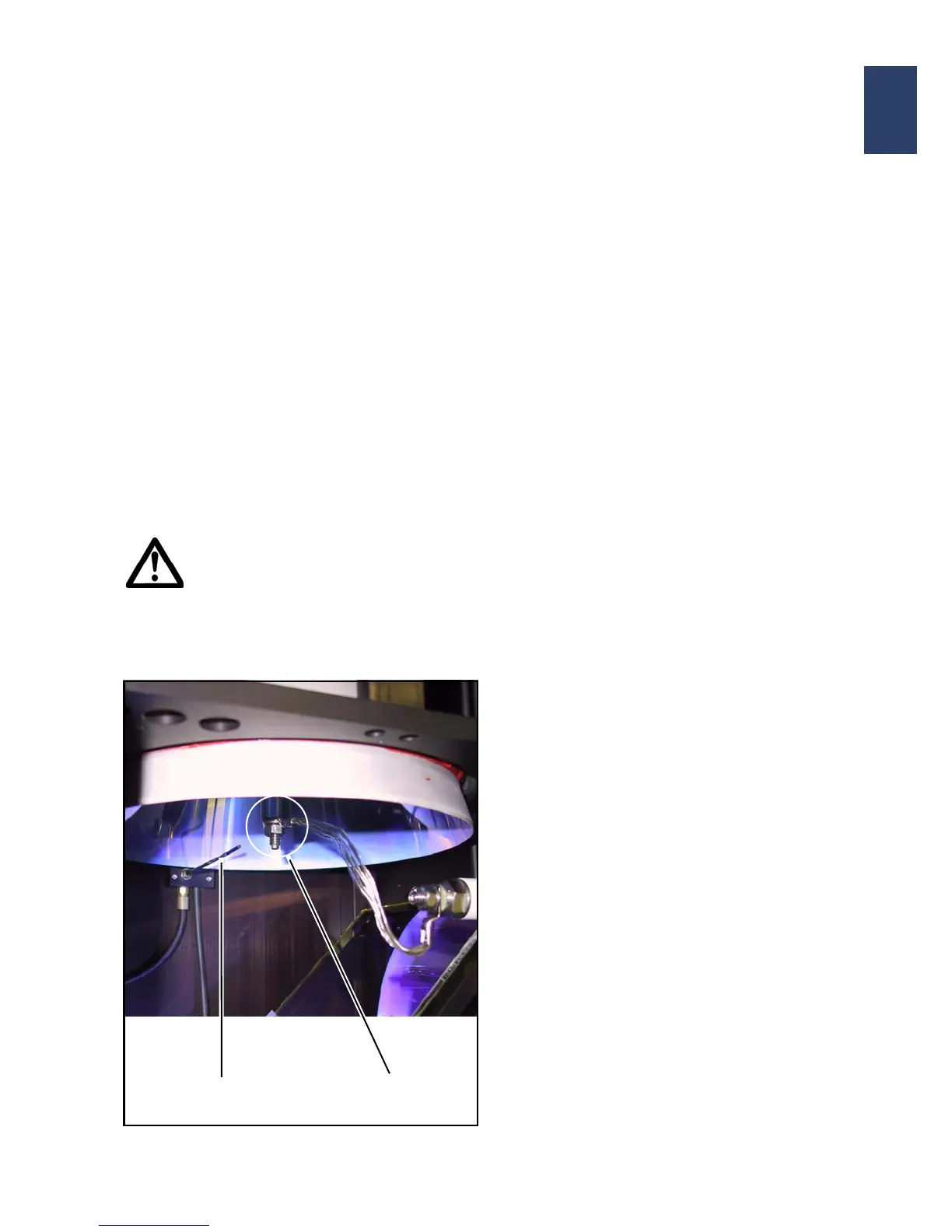

Caution!

Whenever the ellipsoid mirror or the

coldlight mirror has to be exchanged

be sure to readjust the N2-cooling

nozzle (see fig. below) to cool the lower

lamp socket. Otherwise there is a risk

of lamp explosion.

2.4.4. Exhaust Flow Control

(in Lamp house Intake Tube)

The exhaust flow must be adjusted on site during

machine installation using the factory exhaust sys

-

tem.

The settings must follow the data given in section

Utilites and Lamp Cooling.

After final completion of settings, the flow sensor

(which is optional and is - if installed - located in the

lam house air intake bottom tube) can be checked

and readjusted:

• Turn the setting screw in the sensor to the switch-

ing point (indication red/green); then turn back to

green by a half rotation.

2.4.5. Use of Other Lamps

Smaller lamps (550W, 350W) can be used in the

lamp house 1000/1500W if special adapters for the

lamp and for socket cooling are installed.

For required parts and cooling specifications ask

SUSS Service.

2.4.6. Lamp House 350W and

350W Lamp Replacement

The small lamp house differs to the lamp house 100/

1500W in some respect:

• It has no access door on the side, it can be

opened only by tilting the head (the upper part) of

the lamp house. The head is secured to the bot

-

tom segment by a screw with access from top

• It has no interlock to the lamp power supply. Be-

fore opening the 350W lamp house, the lamp

power supply and the machine must always be

switched OFF! Respect the warning labels at

-

tached to the lamp house!

• In standard configuration it does not need ex-

haust for additional cooling or ozone reduction.

Forced N2 socket cooling together with natural

air convection is sufficient to cool the 350W lamp.

The glass bulb of the 350W OSRAM HBO lamp

is especially equipped to minimize deep UV radi

-

ation, resulting in very low ozone generation.

• Basic equipment is the 350W lamp.

Potential other lamps are: 200W or 500W. The

200W lamp requires a special lamp socket adapt

-

N

2

-Cooling Nozzle Lamp Socket

Loading...

Loading...