INSTRUCTION MANUAL

74

¨NOT!¨

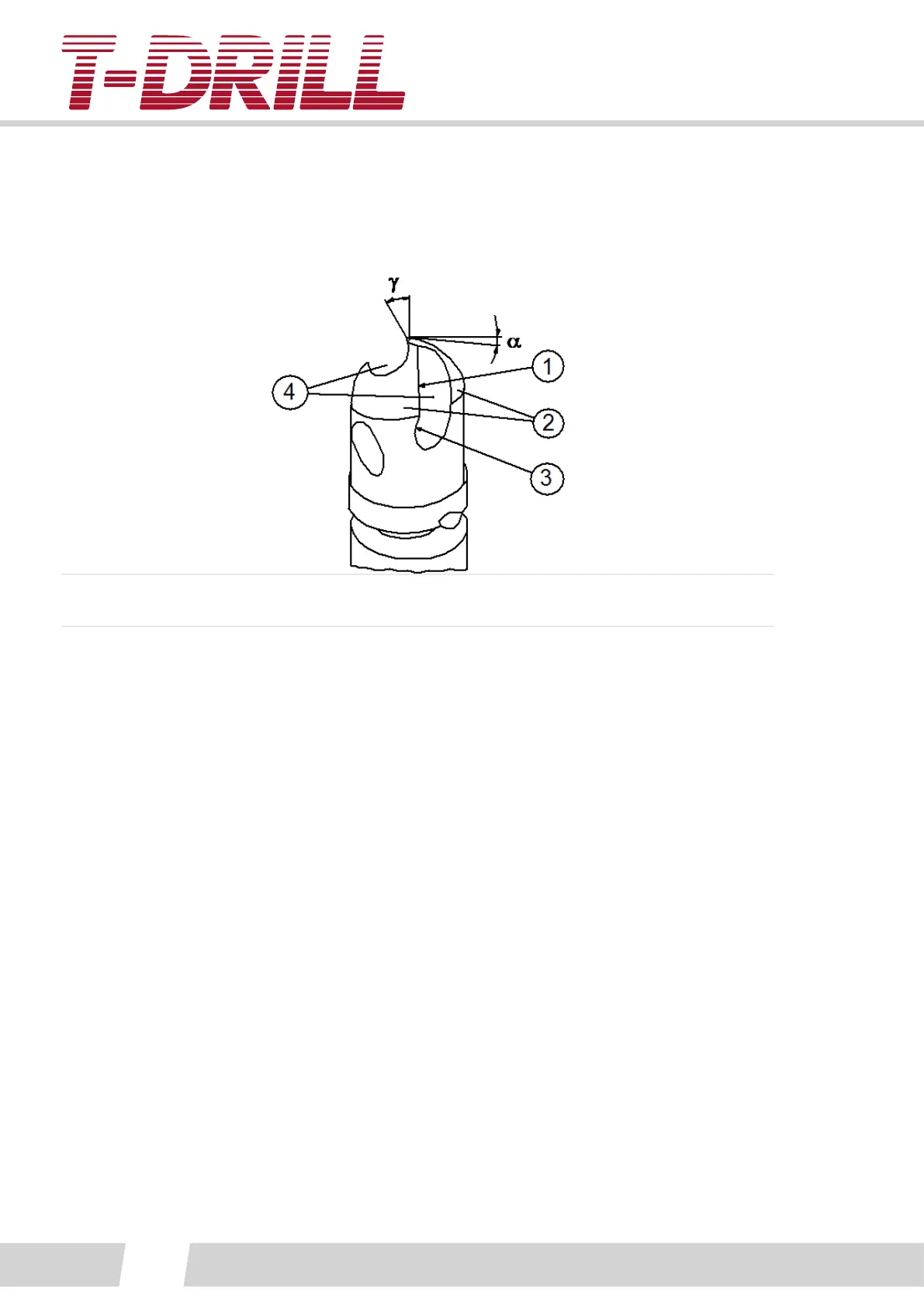

The parts of the bit: α = Clearance angle, ɣ = Chisel edge angle, 1. Cung edge, 2. Body

clearance surface (land), 3. Rake face, 4. Flute.

The patented cung geometry of the T-DRILL bit is designed in such a way that a perfect

pilot hole without burrs can be achieved at a low feed rate. However, this presupposes

that the cung edge is always kept sharp.

When the cung performance of the bit declines, it does not seem to penetrate the tube

surface easily or burrs occur on the edge of the pilot hole, it is me to resharpen. (Note!

Burrs may also be a sign of insucient lubricaon). Use of a dull bit must be avoided,

because a dull bit wears out very quickly and thus its life expectancy will be relavely

short.

The bit is resharpened at the rake face only. The body clearance surface is never to be

sharpened, because even the slightest variaon in the anding angle will radically reduce

the cung characteriscs of the bit.

For the resharpening the following equipment is needed:

- A tool grinding machine equipped with a vercally ltable rotary table

- A ne-grained, thin grinding wheel which ts in the ute

- A straight pin which ts in the cung-groove by means of which it is easier to set the bit

in the correct posion.

1. Fasten the drill shank in the clamping xture and put the straight pin into the ute. Set

the pin parallel with the slide bars of the grinding machine carriage both vercally and

horizontally. (See gure next).

Loading...

Loading...