Preventive Maintenance

Leak Test and Pump Check Out

5-4 Model 48i Instruction Manual Thermo Electron Corporation

Leak Test and Pump

Check Out

There are two major types of leaks: external leaks and leaks across the

optional zero/span solenoid valve seals.

External Leaks Use the following procedure to test for external leaks.

1. Disconnect the sample input line and plug the SAMPLE fitting.

2. Press to display the Main Menu.

3. Press to move the cursor to Diagnostics and press to

display the Diagnostics menu.

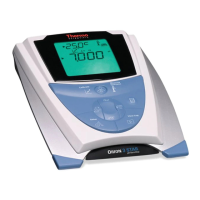

4. Press to move the cursor to Flow and press to display the

Sample Flow screen. The flow reading should indicate zero flow and the

pressure reading should be less than 250 mm Hg. If not, check to see

that all fittings are tight and that none of the input lines are cracked or

broken. For detailed information about this screen, refer to the

“Operation” chapter.

If the pump diaphragm is in good condition and the capillary not blocked,

it should take less than one minute from the time the inlet is plugged to the

time the reading below 250 mm Hg is obtained.

Leaks Across the Optional

Zero/Span and Sample

Solenoid Valves

In order to check for leaks across the optional valves, plug the SPAN inlet

line, press and follow the “External Leaks” procedure.

If the pressure drops below 250 mm Hg the valve associated with the span

line is functioning normally. Repeat for the valve associated with the zero

line by plugging the zero inlet, press and follow the “External Leaks”

procedure.

If the pressure drops below 250 mm Hg, the valve associated with the zero

line is functioning normally.

Loading...

Loading...