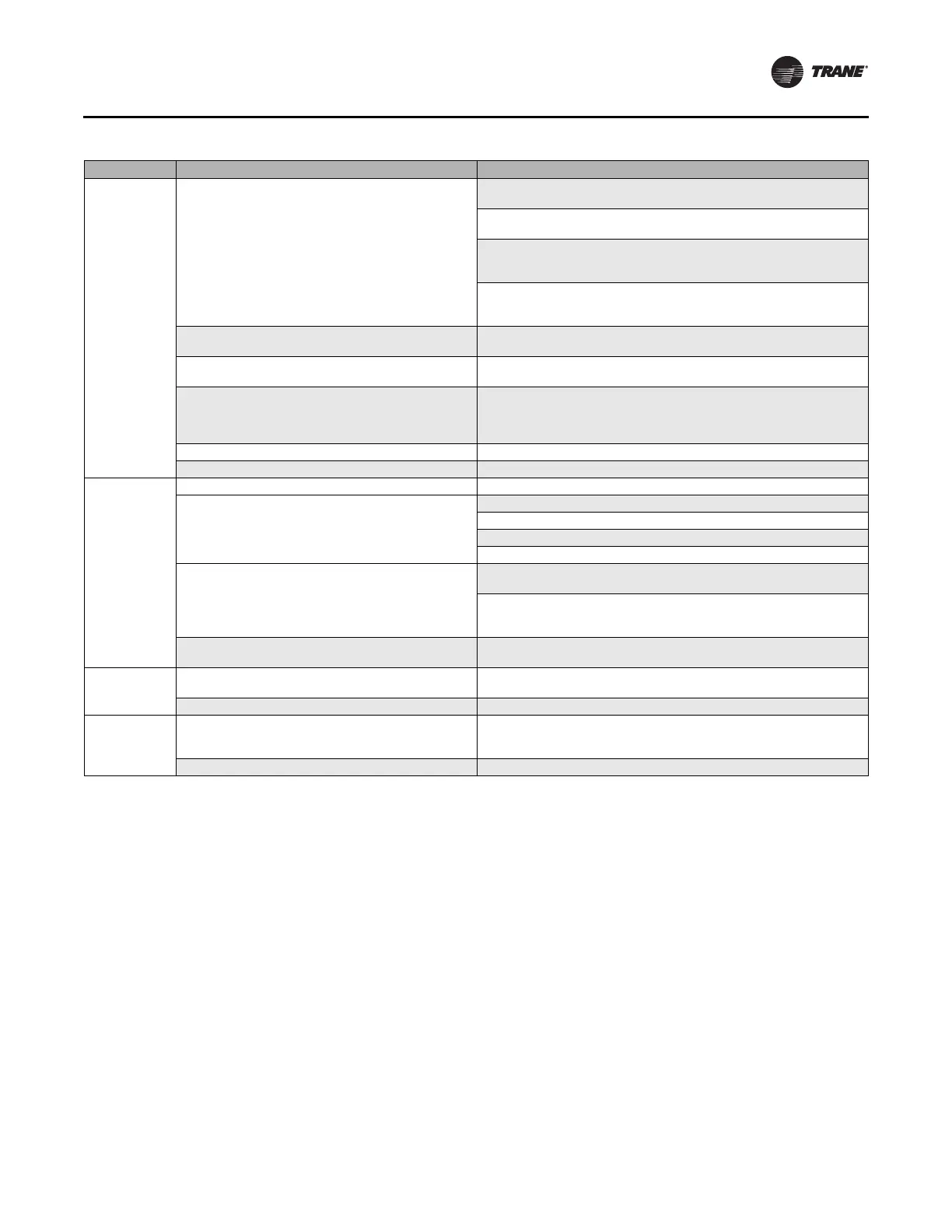

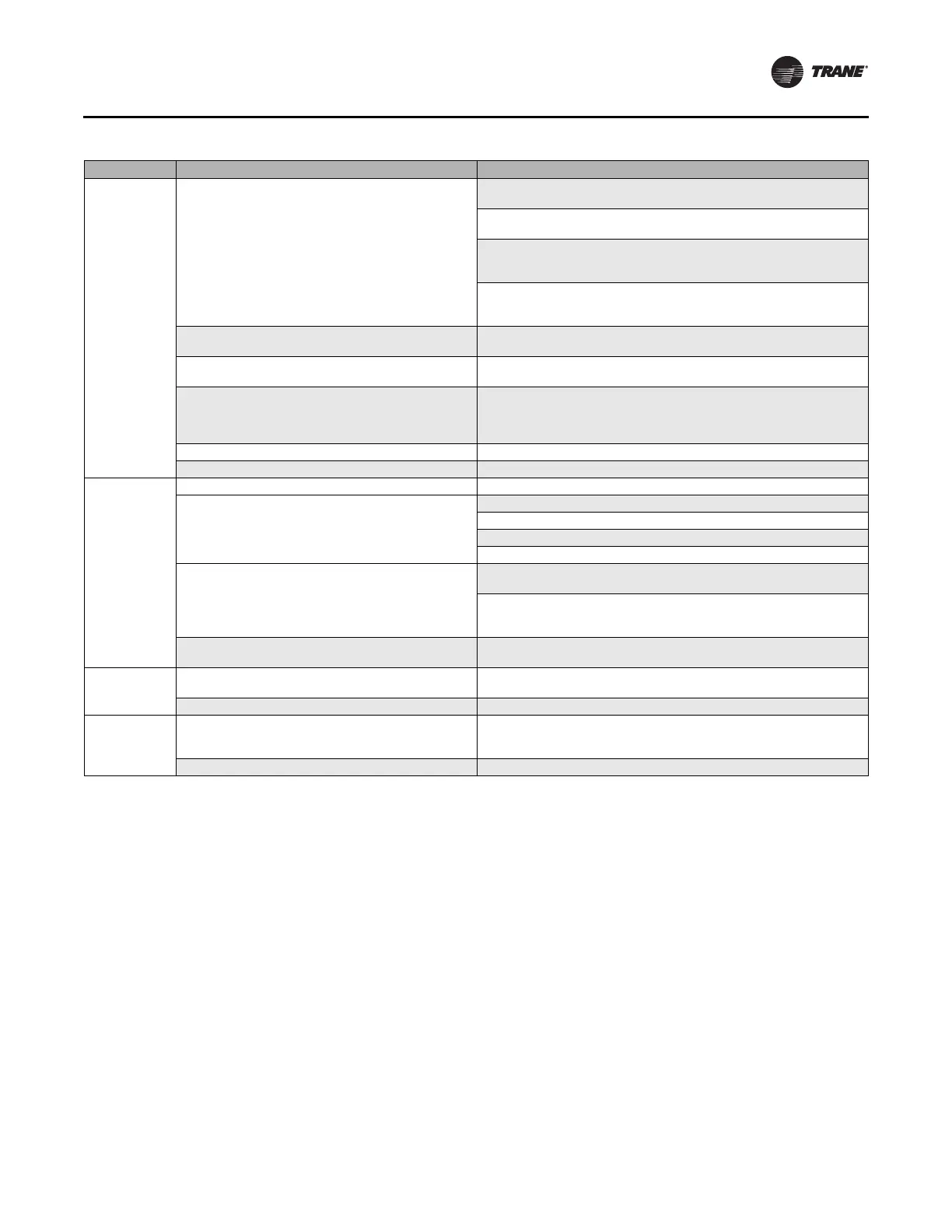

Troubleshooting

CLCH-SVX07K-EN 167

Energy wheel or

CDQ wheel will

not rotate

Motor is not running

The fuse or circuit breaker may be blown or open. Check the breaker/fuse

box and replace.

There may be a loss of incoming power. Attempt to trace the power loss

back to its source and correct.

The motor may have failed. Check for power at the motor terminals. If

present, disconnect the belt from the motor pulley and see if the motor

runs without a load. If it still doesn’t run, replace the motor.

The motor may have failed because it is connected to a variable

frequency drive. Disconnect the VFD and run the motor on 60 Hz power

only.

Excessive friction at the seals

Re-adjust the diameter seals. See “Energy Wheel Seal Adjustment,”

p. 160 or “CDQ Seal Adjustment,” p. 154.

Energy wheel frame or spokes are bent or warped

Inspect the wheel, locate the bent section, and straighten the section or

replace the frame.

During winter operation, excessive frost/ice forms

in the heat transfer media

Disconnect power to the wheel motor, adjust outside air dampers shut

and let the wheel thaw. After the initial section thaws, rotate the wheel

90 degrees by hand until the “new” section rotates into the warm exhaust

air stream. Continue this procedure until the wheel is completely thawed.

Drive belt is broken Inspect visually. Replace the drive belt.

Wheel main shaft bearing is seized Replace the seized bearing.

Loss of energy

wheel capacity

Wheel is not rotating See above

Wheel is rotating too slowly

Belt is stretched, slipping. Replace the belt.

Ice forms on the wheel; thaw per above.

Seized bearing on the main shaft; replace the bearing.

Excessive friction in seals; adjust.

Energy transfer surface is contaminated

Clean the energy transfer surfaces. Consider purchasing a second set of

energy transfer segments for continuous operation while cleaning.

Replace the energy transfer segments if they are severely contaminated

and cannot be cleaned. Consider adding a contaminate filter before

(upstream) the energy wheel.

Frost/ice forms on heat transfer surfaces

Thaw the wheel surfaces per procedure above. Consider adding outside

air preheat.

Worn diameter

seals in energy

wheel

Maximum wheel pressure drop exceeded

Adjust wheel airflow so that the pressure drop across the wheel is less

than 1.25 inches wg.

Seal adjusted too tight Adjust seals. See “Energy Wheel Seal Adjustment,” p. 160.

UV light fails

Ballast fails to energize light.

Disconnect high voltage leads (green, white, and black connectors) from

the ballast enclosure. Wait for three minutes, this will reset the end-of-

light circuitry and then reconnect.

End of life. Replace bulb. See “Replacing the Bulbs,” p. 163.

Table 56. Air handler troubleshooting recommendations (continued)

Symptom Probable Cause Recommended Action

Loading...

Loading...