Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Troubleshooting

7-6 Profimat 23 E

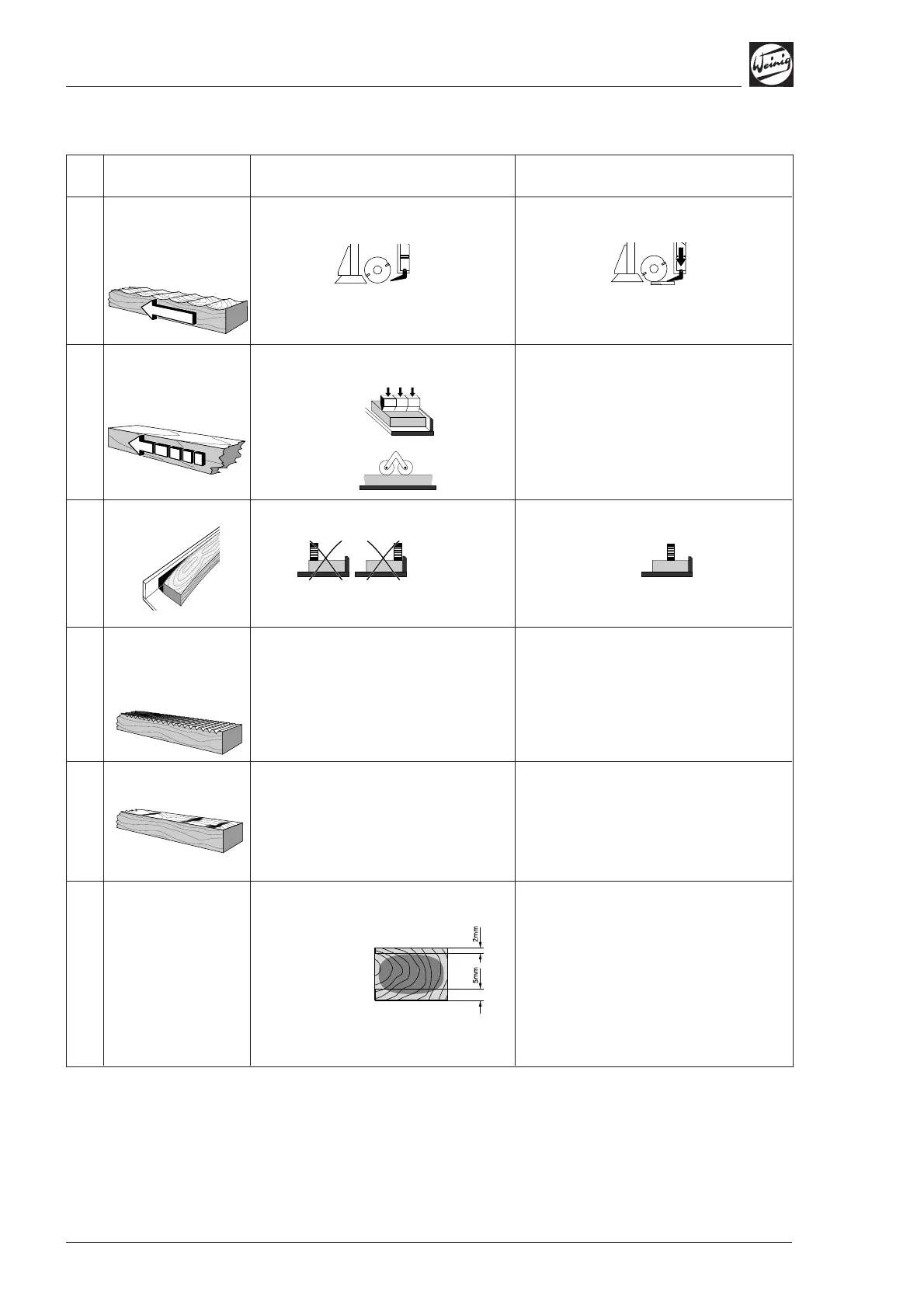

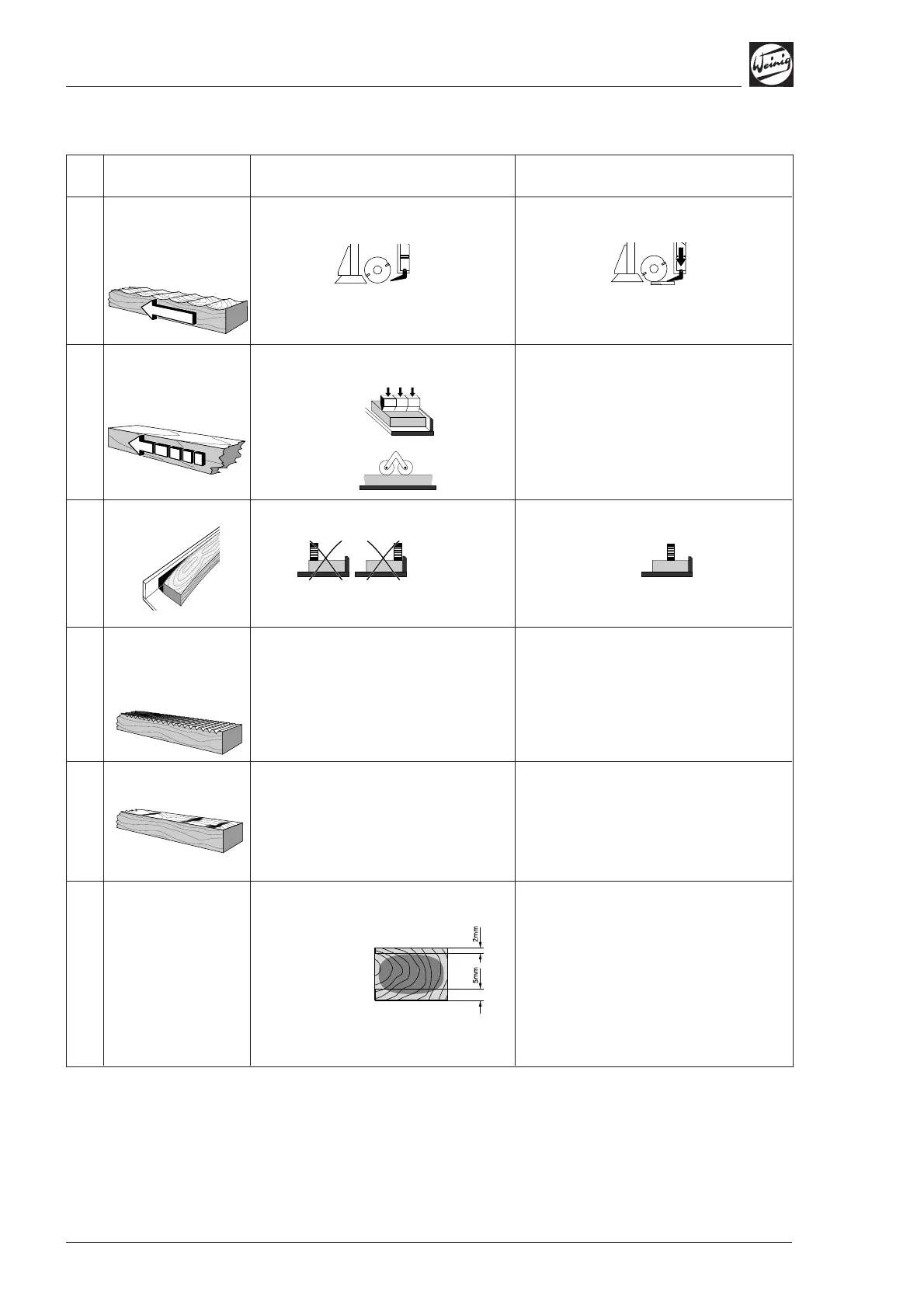

a) Workpiece wobbles because pressure

elements not set correctly

a) Pressure elements at top and front of

left-hand spindle set to too strong a

value

b) Feed beam too high

a) Top feed rollers set incorrectly

b) Pressure elements set incorrectly from

the left

a) Raw timber with too little oversize

b) Excessive chip removal at the

straightening spindle

c) Feed rate too high

a) Feed rate too low, tool scrapes

b) Timber has briefly stopped in the

machine

c) Tool is blunt

a) Irregular chip removal on opposite

sides or when timber is strongly

profiled

b) Timber has been dried incorrectly

Remedy fault

No.

Possible cause

Fault

Irregular marks on

the top over the full

length of the work-

piece

Timber does not run

through the machine

(congestion)

Timber wanders away

from fence

Feed roller impres-

sions visible on the

surface of the timber

Burn marks in the

timber

Timber warps after

machining

b) Set pressure elements correctly

a) Reduce hold-down pressure of lateral

and upper pressure elements

b) Adjust height of feed beam

a) Set feed rollers to middle of workpiece

b) Check all pressure elements

a) Use raw timber with larger oversize

b) Reduce chip removal on straightening

spindle

c) Reduce hold-down pressure of feed

a) Increase feed rate (cutter mark

calculation)

b) Do not leave test timber under one

spindle for too long when working at

inching feed rate

c) Regrind tool

a) Uniform chip removal on both sides

b) Use well seasoned timber with uniform

moisture content in core and exterior

wood

13

14

15

16

17

18

Loading...

Loading...