Installation Yamatake Corporation

4-16 ST3000 Smart Transmitter Series 900 Electronic Differential Pressure/Pressure Transmitter

(4) Determine the connecting pipe schedule number and the nominal thickness of the

connecting pipe from the process based on conditions such as the process pressure.

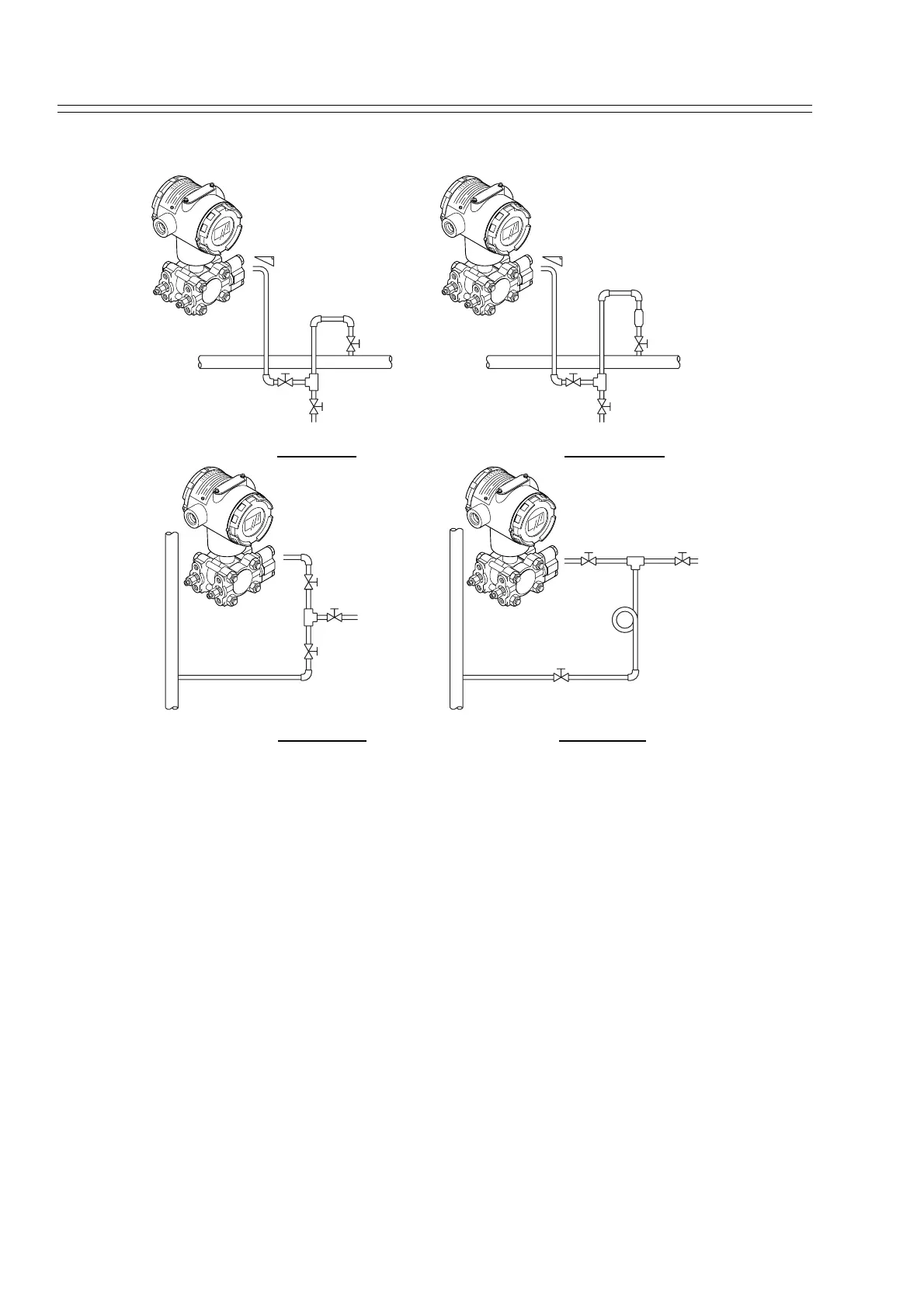

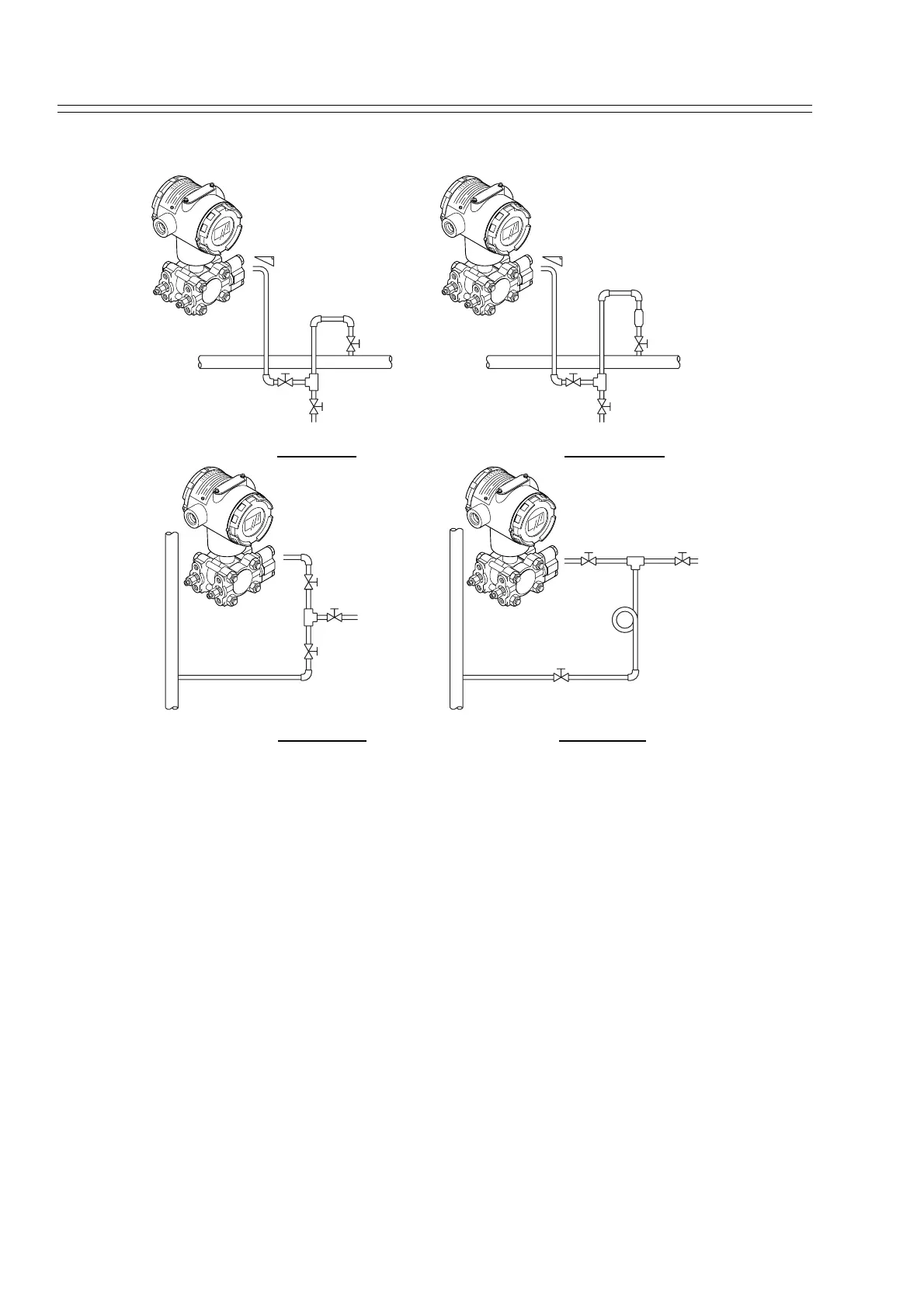

Figure 4-12 Example of Piping

Auxiliary equipment

(1) Oil sealing and air purging

If the pressure medium (such as suspension, high viscosity, and corrosive fluid) should

not be led directly to the element, avoid it by means of sealing or purging. Various

sealing and purging methods are available. Consult us for each case.

(2) Preventing pulsations

If the process has serious pulsations or great pressure fluctuations, provide a throttle

valve in the middle of the connecting pipe to prevent pulsations.

Capacitor

Main valv

Main valve

Main valve

Main valve

Local valve

Local valve

Local valve

Local valve

Drain valveDrain valve

Drain valve

Drain valv

ProcessProcess

Process Process

Siphon

C. Moist gasA. Liquid

B. Dry gas D. Steam

Loading...

Loading...