Yamatake Corporation Installation

ST3000 Smart Transmitter Series 900 Electronic Differential Pressure/Pressure Transmitter 4-15

4-3-2 :Pressure Measurement - Piping

Recommended piping - Example

For gas-pressure measurement, piping should be performed following the typical

example shown here. Always observe these points:

At the differential pressure output, make pipe vertical.

After completing piping work, check for pressure leaks around connecting pipe and

transmitter.

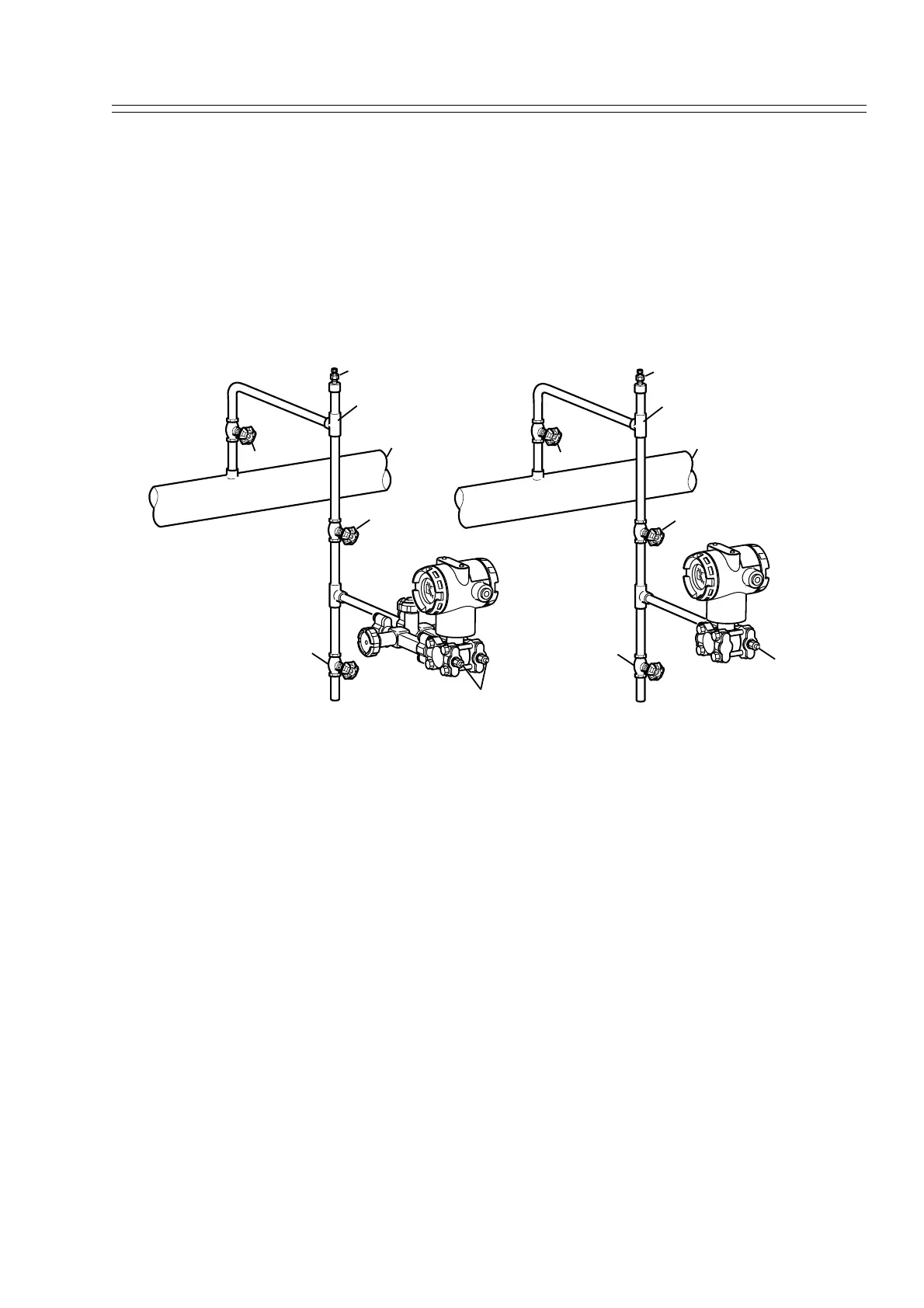

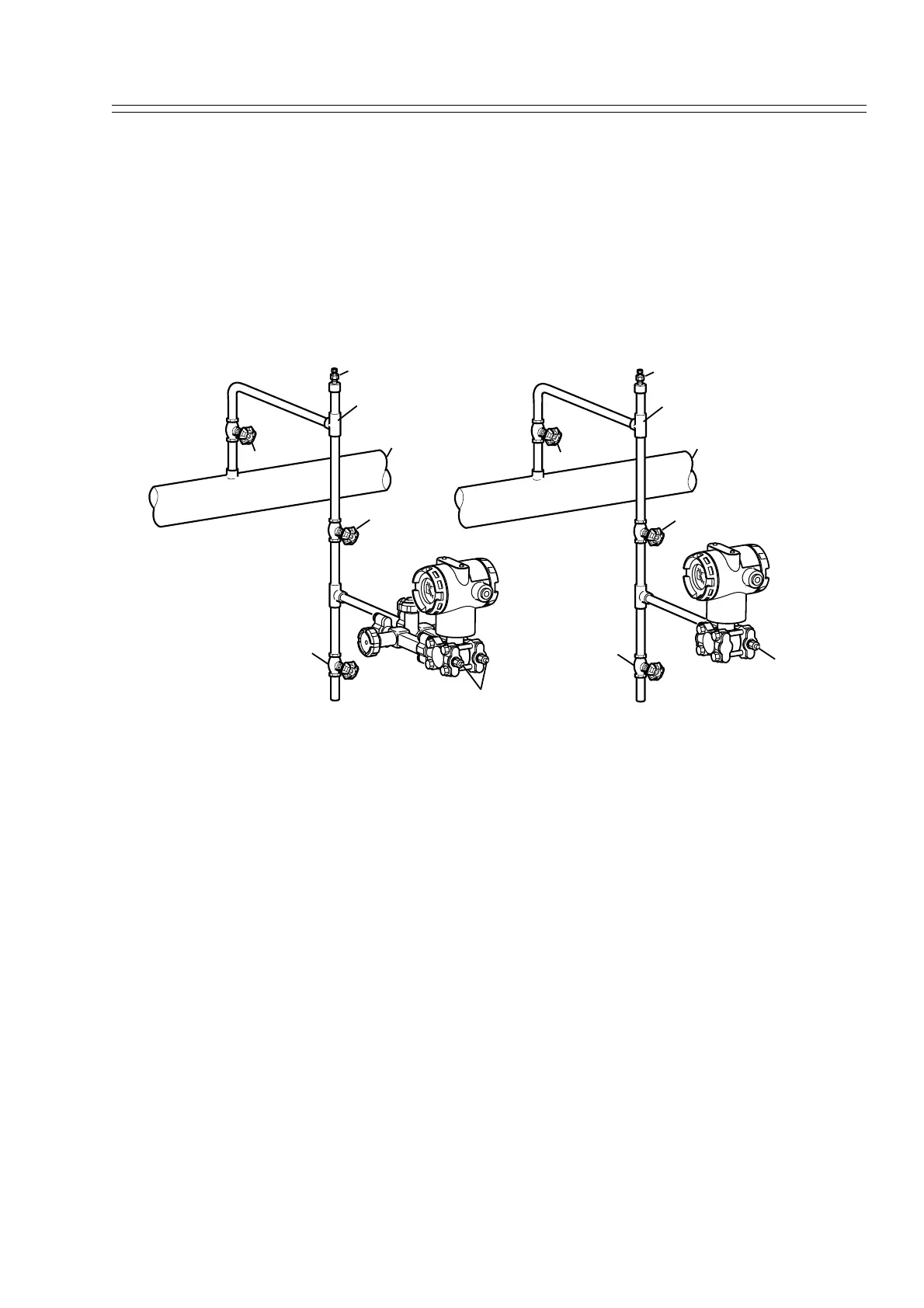

Figure 4-11 Gas Pressure Measurement - Piping

Piping method

The piping method for the fluid to be measured depends on the meter installation posi-

tion and the pipe line state. Typical examples of piping are shown in Figure 4-12.

Connect pipes by the following procedure:

(1) Use a T-shaped joint for the connecting pipeline.

(2) Install a main valve between the entrance of the connecting pipe and the T-shaped

joint.

(3) If the process is a horizontal line, tilt the pipe to allow draining from the pressure

line.

~Note In case of a high pressure process, select a joint of appropriate specifica-

tions and shape and a pipe of appropriate shape and material with care.

Gas vent plug

Local valve

Main valve

Drain valve

Vent / Drain plug

Process pipe

Tee

STD type Transmitter

Gas vent plug

Main valve

Local valve

Drain valve

Vent / Drain plug

Process pipe

Tee

STG / STA type Transmitter

Loading...

Loading...