Installation Yamatake Corporation

4-12 ST3000 Smart Transmitter Series 900 Electronic Differential Pressure/Pressure Transmitter

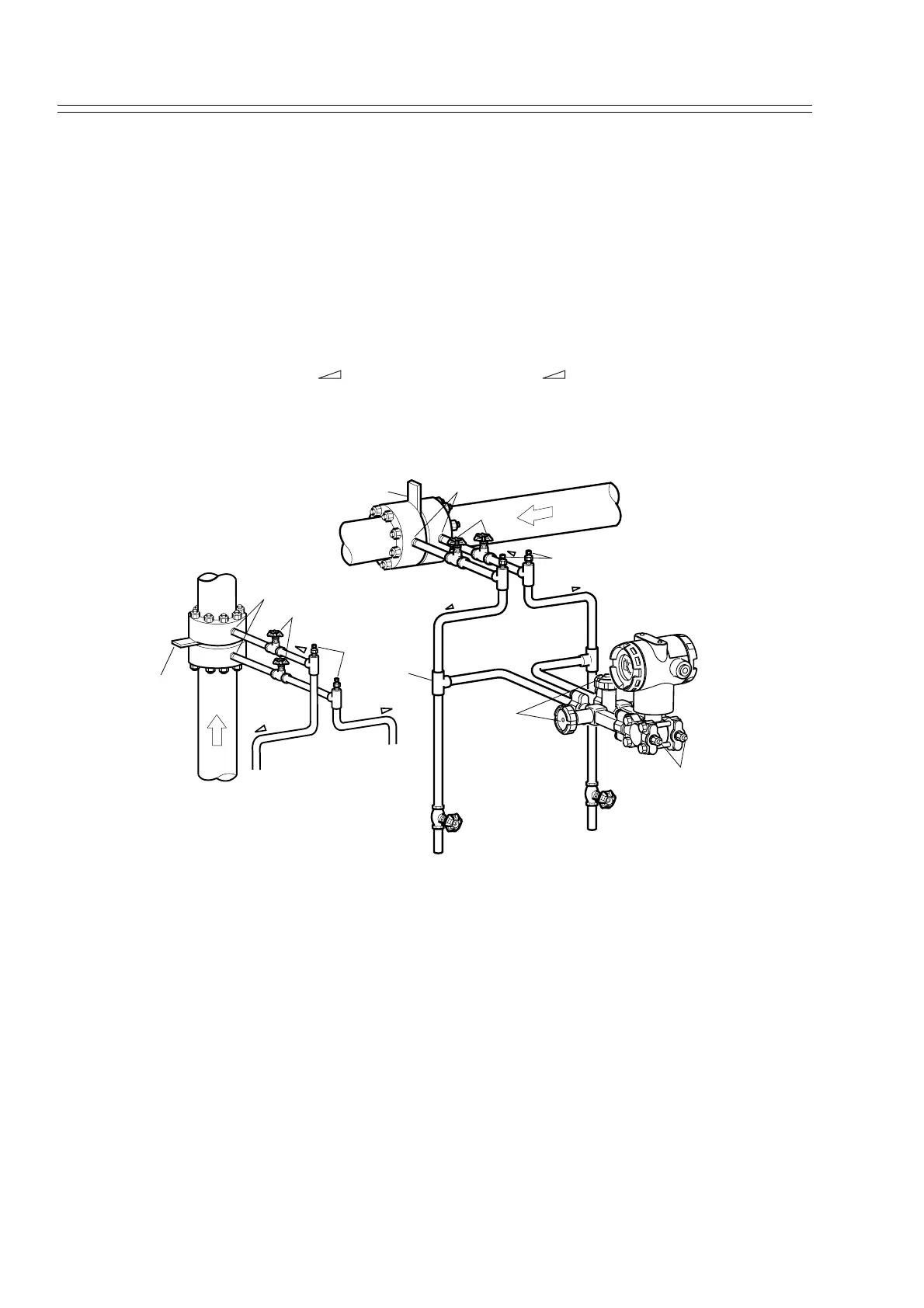

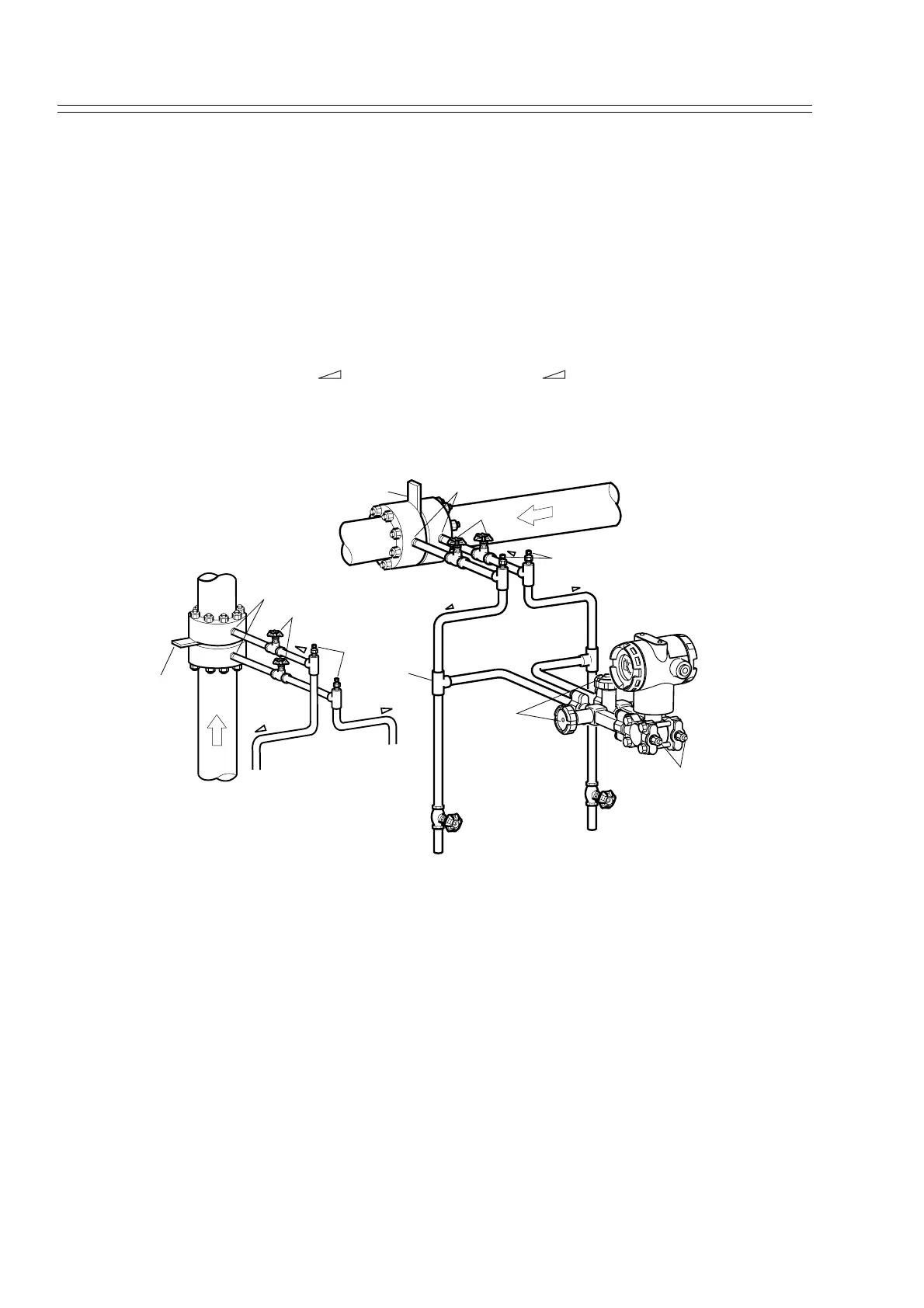

4-3-1 :Piping for Liquid, Gas or Steam Flow Rate Measurement

Recommended Piping -- Example 1

The illustration shows a typical example for liquid Flow Rate Measurement. This Dif-

ferential pressure transmitter is located below the differential pressure output port of

the process pipe.This minimizes the static head effect of the condensate.

The following apply:

Grade the pipe at the differential pressure output part.

Inclination symbol in illustration: Low level High level

After piping work, ensure that the connecting pipe, the 3-way manifold valve, and the

transmitter have no pressure leak.

Figure 4-8 Piping for Liquid Flow Rate Measurement (Example)

This transmitter is located underneath the differential pressure output port of the pro-

cess pipe.

Main valve

Orifice

Gasvent valve

Differential pressure output port

3-way

manifold valve

Low pressure side

High pressure side

Drain valve

Drain valve

Vent / Drain plug

Tee

Inclination

Inclination

Inclination

Differential pressure output port

Orifice

High pressure side

Low pressure side

Main valve

Gas vent valve

Inclination

Inclination

Inclination

Loading...

Loading...