Acceleration and Deceleration Characteristics

5-21

5

Stall Prevention During Acceleration

The Stall Prevention During Acceleration function prevents the motor from stalling if the load is too heavy.

If L3-01 is set to 1 (enabled) and the Inverter output current reaches 85 % of the set value in L3-02, the accel-

eration rate will begin to slow down. When L3-02 is exceeded, the acceleration will stop.

If L3-01 is set to 2 (optimum adjustment), the motor accelerates so that the current is held at the level set in

L3-02. With this setting, the acceleration time setting is ignored.

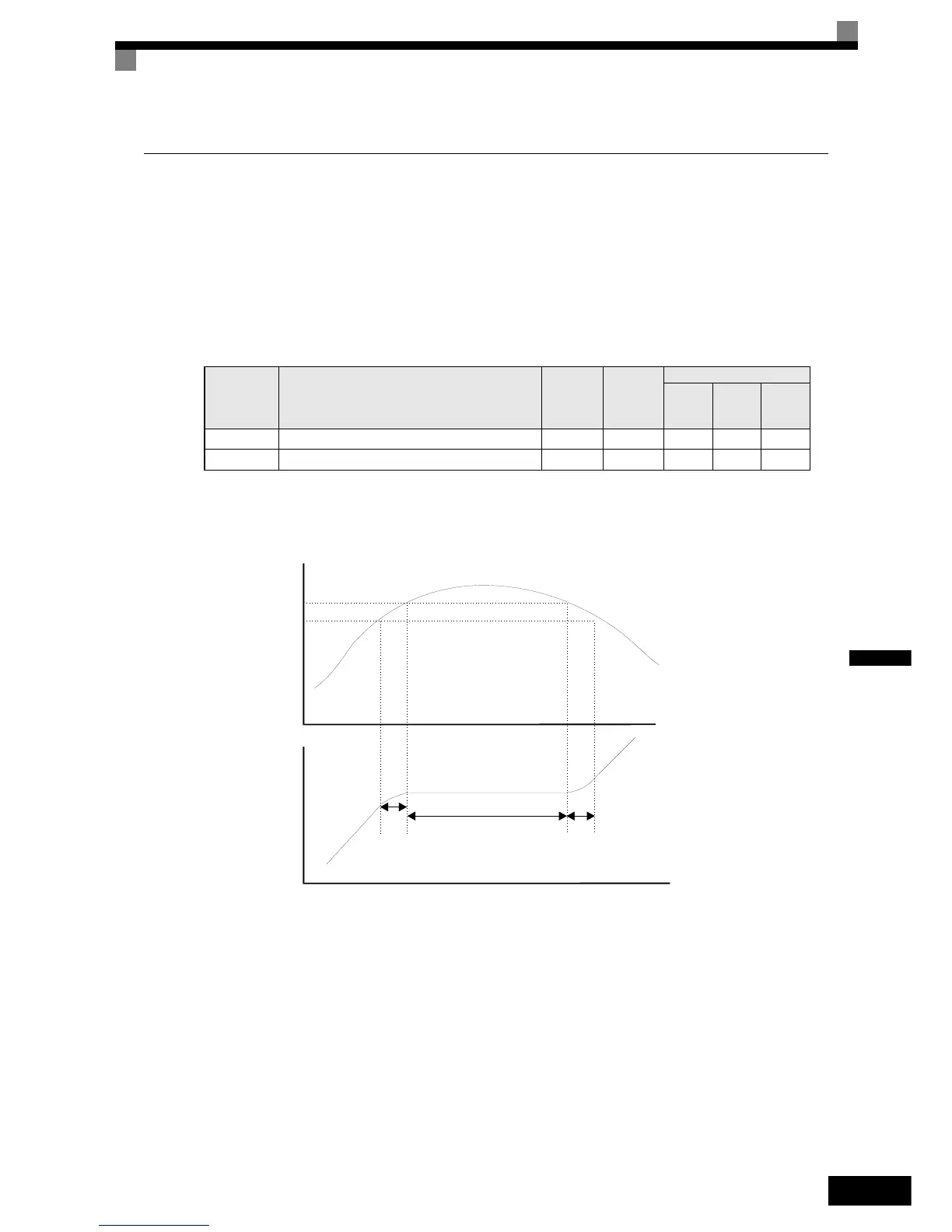

Related Parameters

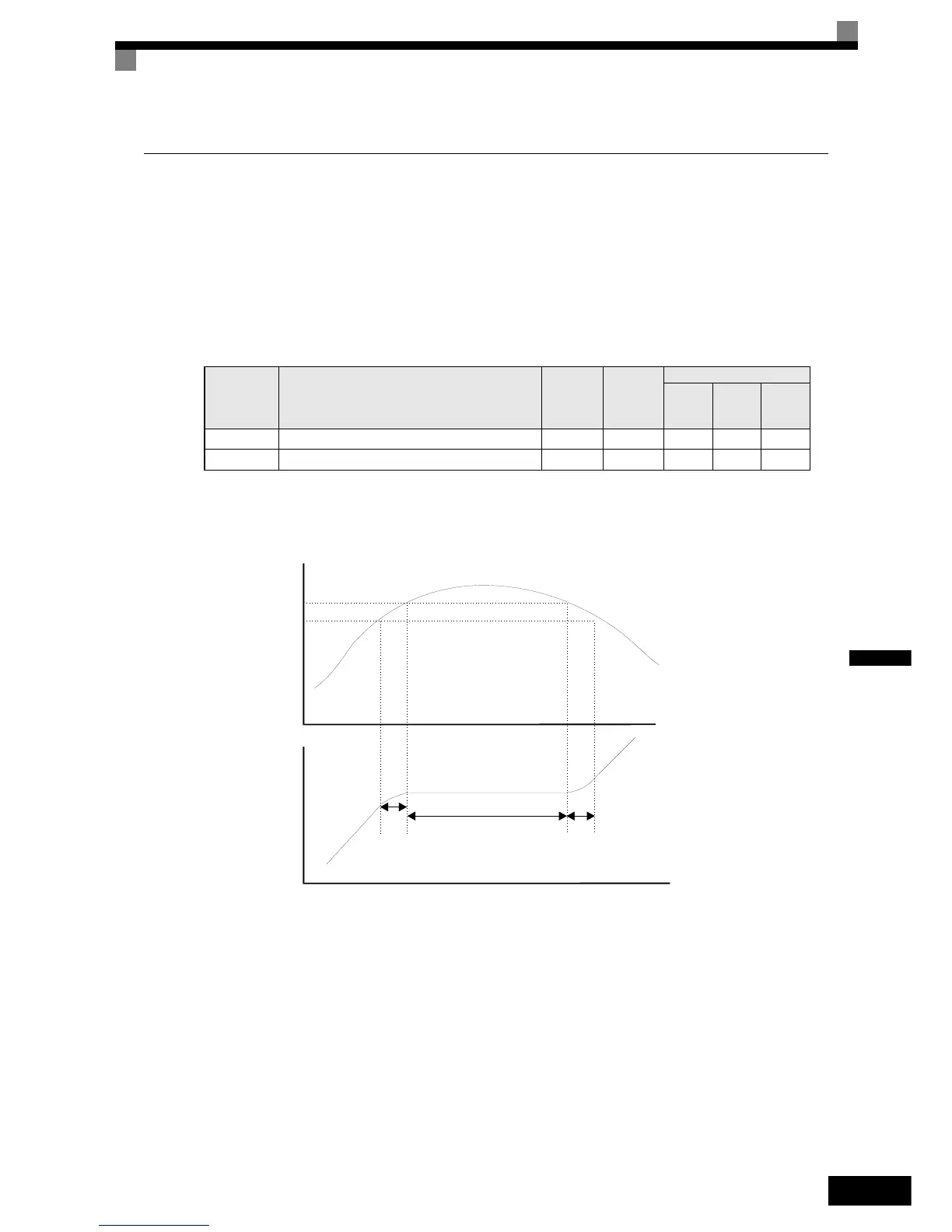

Time Chart

The following figure shows the frequency characteristics when L3-01 is set to 1.

Fig 5.9 Time Chart for Stall Prevention During Acceleration

Setting Precautions

• Set the parameters as a percentage taking the inverter rated current to be 100%.

• Do not increase the stall prevention level unnecessarily. An extremely high setting can reduce the inverter

lifetime. Also do not disable the function.

• If the motor stalls with the factory settings check the V/f pattern settings (E1-) and the motor setup

(E2-).

• If the stall level has to be increased very much to get the elevator running, consider to use a one size bigger

inverter.

Parameter

No.

Name

Factory

Setting

Change

during

Operation

Control Methods

V/f

Open

Loop

Vector

Closed

Loop

Vector

L3-01 Stall prevention selection during acceleration 1 No A A No

L3-02 Stall prevention level during acceleration 150%* No A A No

Output current

Stall level during

acceleration

Time

Time

Output frequency

* 1. The acceleration rate is lowered.

* 2. The acceleration is stopped to reduce the output current.

*1.

*2.

L3-02

85% of L3-02

http://nicontrols.com

Loading...

Loading...