603D SYSTEMS, INC.

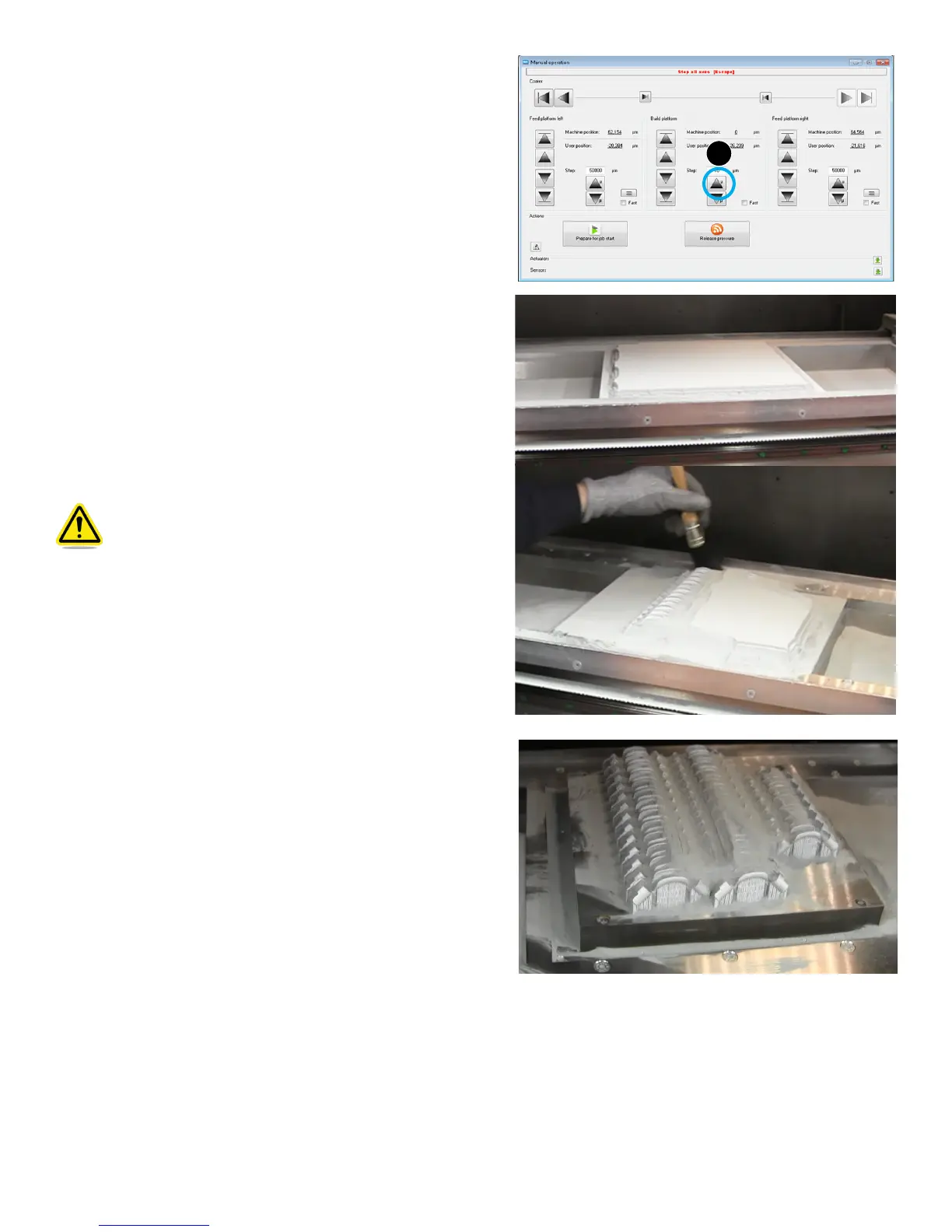

6. Move the feeds down by about 10mm.

7. Move the build platform up by about 20 mm.

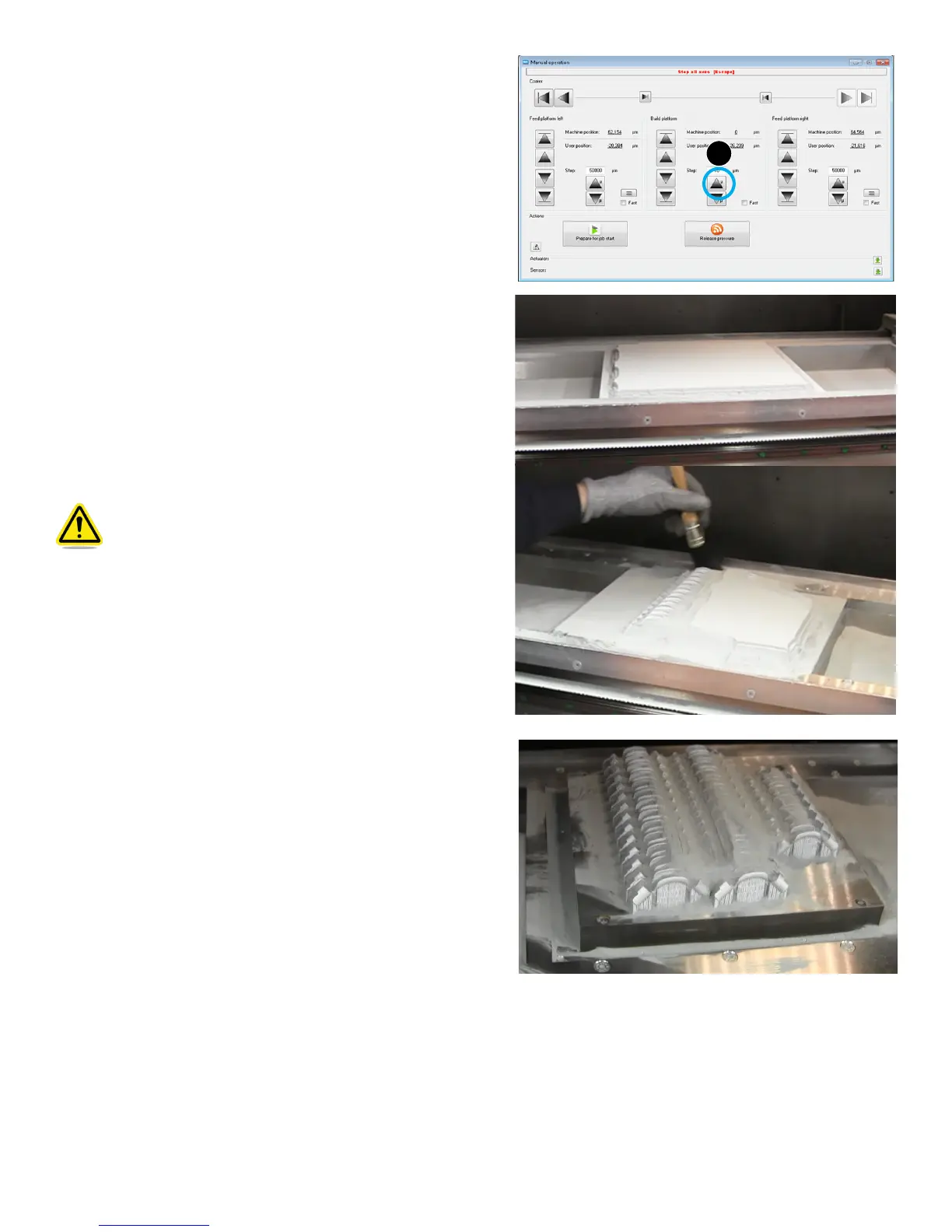

8. Gradually brush the excess powder off into the bins.

WARNING: Any time powder material is handled (i.e.,

relling, sifting, changing, etc.) make sure you are either

standing on an anti-static mat, or you are wearing a

grounding strap that is attached to the module so that

you are grounded to the machine. Always pour or scoop

slowly from as close to surface as possible to avoid

producing dust from material. It is also advised that the

vacuum dust extractor be over top of the bin.

9. Continue moving the build platform up 20 mm at a time, lowering

the feeds with steps of 100 mm when needed and brushing away

the powder until you have most of the visible powder removed as

shown.

10. Continue removing the excess powder by tapping the back of the

print platform with a rubber mallet.

11. Change the orientation of the platform several times and continue

tapping with the rubber mallet. This will ensure that you get as

much of the loose powder as possible out of crevices of parts.

12. When you have removed as much of the loose powder as

possible print can now be post processed. See the Post

Processing Guide for information on post processing a part.

13. Take the natural bristle brush and brush the remaining powder

from where the platform was removed into the bins until there is

no powder in this area.

4

Loading...

Loading...