Parameters 303

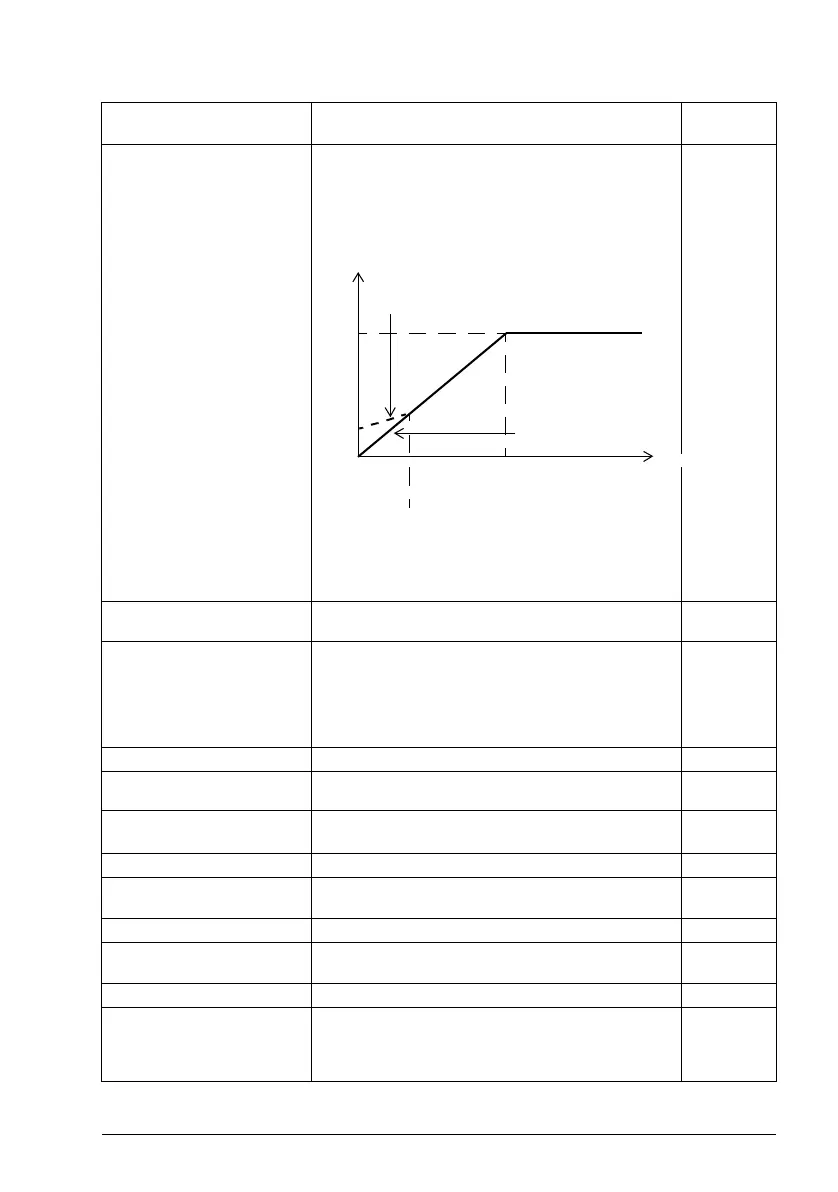

97.13 IR compensation Defines the relative output voltage boost at zero speed (IR

compensation). The function is useful in applications with

a high break-away torque where vector control cannot be

applied.

See also section IR compensation for scalar motor control

on page 69.

3.50%

0.00…50.00% Voltage boost at zero speed in percent of nominal motor

voltage.

1 = 1%

97.15 Motor model

temperature

adaptation

Selects whether the temperature-dependent parameters

(such as stator or rotor resistance) of the motor model

adapt to actual (measured or estimated) temperature or

not.

See parameter group 35 Motor thermal protection for

selection of temperature measurement sources.

Disabled

Disabled Temperature adaptation of motor model disabled. 0

Estimated temperature Estimated temperature (35.01 Motor estimated

temperature) used for adaptation of motor model.

1

97.16 Stator temperature

factor

Tunes the motor temperature dependence of stator

parameters (stator resistance).

50

0.00…200.00% Tuning factor.

97.17 Rotor temperature

factor

Tunes the motor temperature dependence of rotor

parameters (eg. rotor resistance).

100

0.00…200.00% Tuning factor.

97.20 U/F ratio Selects the form for the U/f (voltage to frequency) ratio

below field weakening point. For scalar control only.

Disabled

Linear Linear ratio for constant torque applications. 0

Squared Squared ratio for centrifugal pump and fan applications.

With squared U/f ratio the noise level is lower for most

operating frequencies. Not recommended for permanent

magnet motors.

1

No. Name/Value Description Default

FbEq 16

U / U

N

(%)

f (Hz)

Field weakening point

Relative output voltage. No

IR compensation.

Relative output voltage. IR

compensation set to 15%.

15%

100%

50% of nominal

frequency

Loading...

Loading...