-EN Rev. E Operating instruction SCK Gas Sampling System 131

Step Procedure

Insert the gas sampling probe into the kiln using the

touchscreen.

Path: Operation ► Probe ► Probe Action ► Insert

Observe the following:

horizontal and vertical alignment of the gas sampling

probe in relation to the opening in the mounting flange

stability of the probe retractor fastening elements

unobstructed mobility of all cable and hose connec-

tions

even movement of the probe carriage

Wait for cooling water to heat up: After inserting the probe, the

gas sampling system has a warm-up time to reach the neces-

sary operating temperature. The

Measured Value on Hold

sig-

nal is only reset once the cooling temperature reaches a mini-

mum temperature of 50 °C. Once this signal is active, make

sure that no sample gas is sucked in by the gas sampling

Switch the gas sampling probe to automatic mode using the

touchscreen.

Path: Operation ► Automatic on / off

Result: The sampling system is thus in automatic mode and monitors itself.

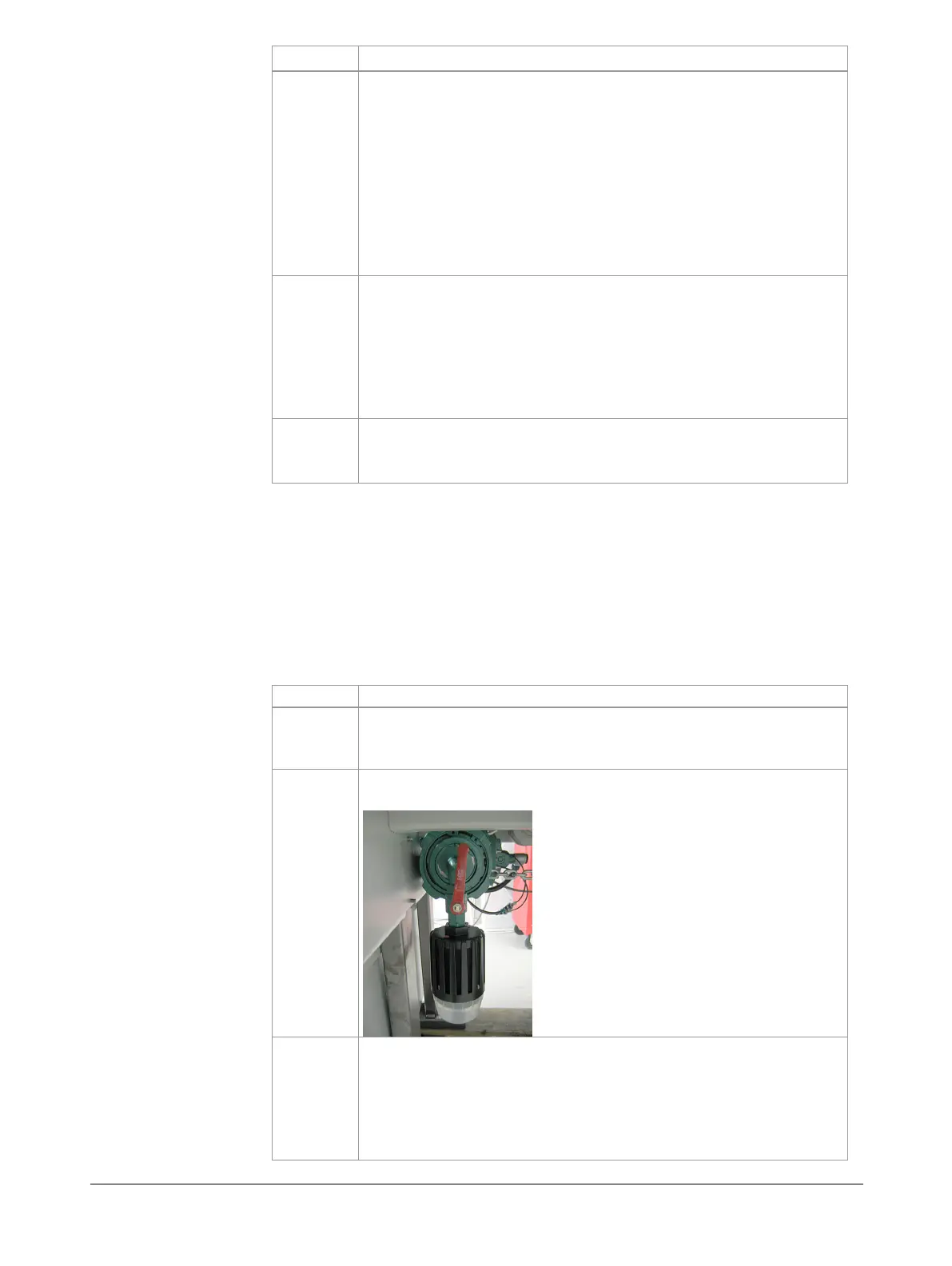

After switching on the gas sampling system there may be differences in

probe retractor travel speed depending on the capacity of the compressed-air

supply provided by the customer. The travel time for one insertion/retraction

of the gas sampling probe must be approx. 20 seconds. You can adjust travel

speed as follows:

Turn service switch to

ON

position.

WARNING! The probe moves out of the kiln. Do not stand in the

area of travel of the probe or probe carriage.

Adjust travel speed to the desired setting using the ball valve

on the compressed-air motor.

Turn service switch back to

OFF

position and insert probe

again using the controller.

WARNING! Probe moves into the kiln. Do not stand in the area

of travel of the probe or probe carriage until the probe is

completely inserted into the kiln and the warning lamps go

probe carriage speed

Loading...

Loading...