132 Operating instruction SCK Gas Sampling System OI/SCK-EN Rev. E

In controller: wait for heating-up time.

"C. Water Return Temp. MIN"

Path: Diagnosis ► Message

In controller: switch gas sampling probe to AUTOMATIC mode:

Path: Operation ► Automatic on / off

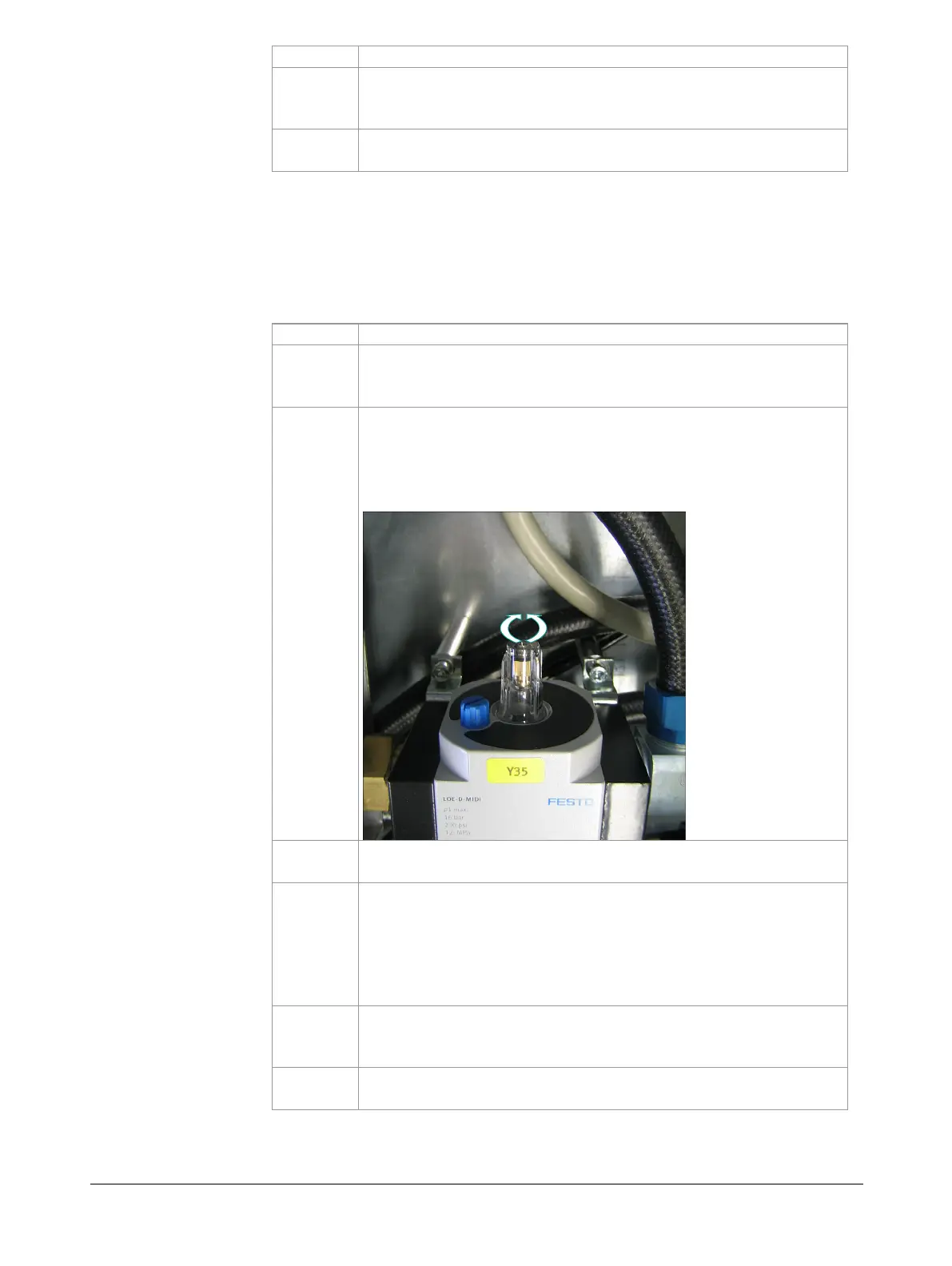

The compressed-air oiler must deliver approx. 2 drops of oil per inser-

tion/retraction cycle. If this is not ensured, the compressed-air motor may

get damaged or this may lead to excessive soiling of the muffler. How to

change oil delivery quantity on the compressed-air oiler (note: two people

should perform this job):

Turn service switch to

ON

position.

WARNING! The probe moves out of the kiln. Do not stand in the

area of travel of the probe or probe carriage.

Turn the setting screw in the inspection glass to modify the

quantity of oil.

Meaning of the directions of rotation:

clockwise less oil

Move probe in/out to check oil quantity, modify again if neces-

sary.

Turn service switch back to

OFF

position and insert probe

again using the controller.

WARNING! Probe moves into the kiln. Do not stand in the area

of travel of the probe or probe carriage until the probe is

completely inserted into the kiln and the warning lamps go

In controller: wait for heating-up time.

"C. Water Return Temp. MIN"

Path: Diagnosis ► Message

In controller: switch gas sampling probe to AUTOMATIC mode:

Path: Operation ► Automatic on / off

the compressed-air

oiler

Loading...

Loading...