SensyMaster FMT430, FMT450 THERMAL MASS FLOWMETER | OI/FMT430/450-EN REV. B 25

Device description

The SensyMaster FMT430, FMT450 works in accordance with the

measuring principle of a hot-film anemometer. This

measurement method allows for direct measurement of the gas

mass flow.

Taking into account the standard density, the norm volume flow

can be displayed without the need for additional pressure and

temperature compensation.

The transmitter is equipped with an analog / HART® output

(4 to 20 mA) and two fast digital outputs that can be configured

as pulse, frequency or binary outputs.

Optionally, the transmitter can be extended using plug-in cards

with further inputs and outputs as well as a Modbus® or

PROFIBUS DP® interface.

The SensyMaster FMT430, FMT450is used in the process

industry for the flow measurement of gases and gas mixtures.

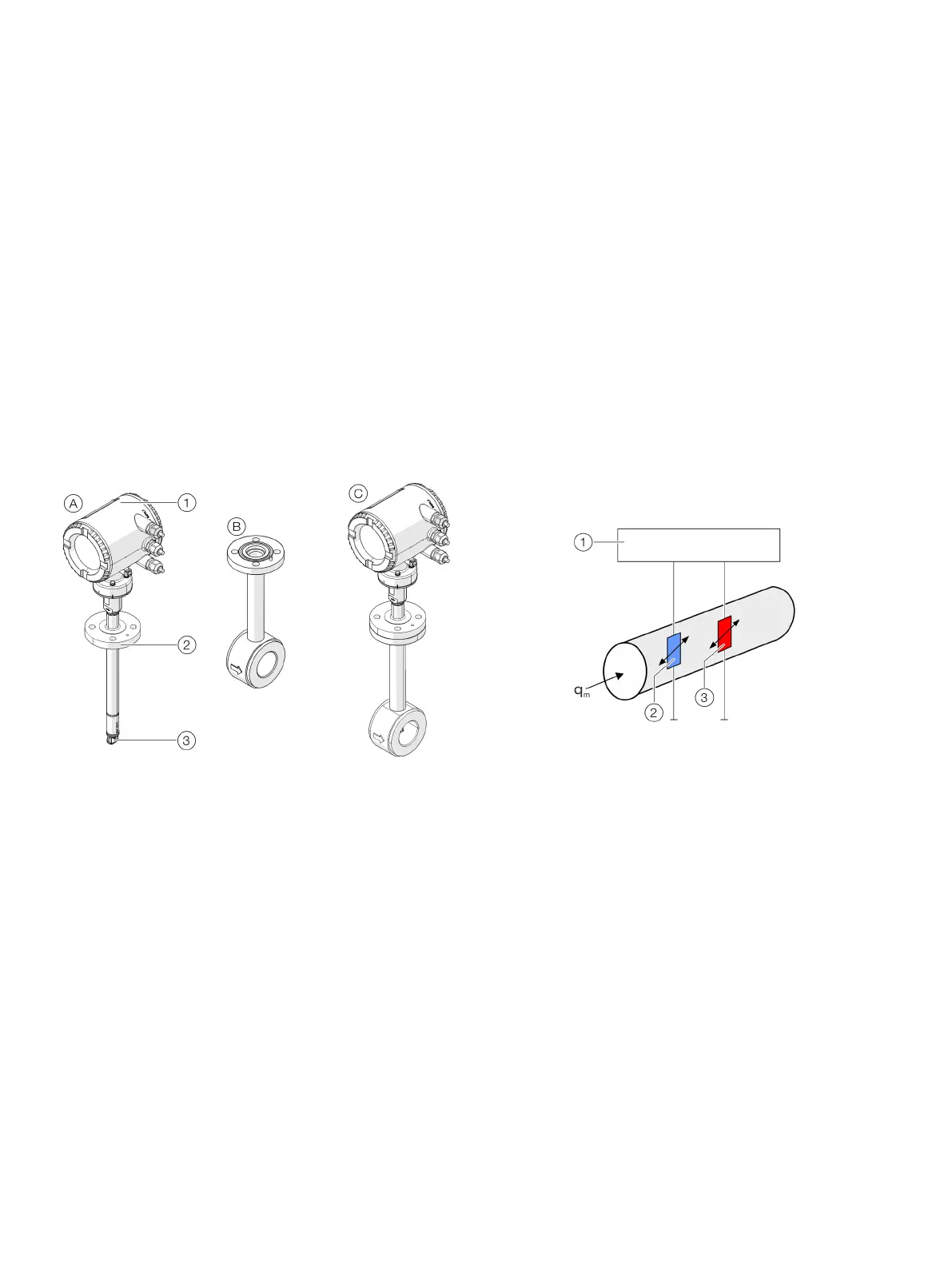

Sensor

Pipe component

Sensor with pipe component

Transmitter

Sensor connection

Thermal sensor elements

Figure 8: Sensor (example, wafer type design)

The SensyMaster FMT430, FMT450 is composed of the

components sensor and pipe component (process connection).

The pipe component can be delivered in various designs. In

addition, a weld-on adapter makes it possible to install the

flowmeter sensor in rectangular ducts or pipelines with any

diameter.

Measuring principle

Thermal flow metering procedures use different ways to

evaluate the flow dependent cooling of a heated resistor as

measuring signal.

In a hotfilm anemometer with constant temperature difference

control, the heated platinum resistor is maintained at a constant

overtemperature in relation to an unheated platinum sensor

inside the gas flow.

The heating power required for maintaining the

overtemperature depends directly on the flow rate and the

material properties of the gas. With a known (and constant) gas

composition the mass-flow can be determined by electronically

evaluating the heater current / mass-flow curve without

additional pressure and temperature compensation.

Together with the standard density of the gas this results

directly in the standard volume flow.

Considering the high measuring range dynamics up to 1:100, an

accuracy smaller than 1 % of the measuring value is achieved.

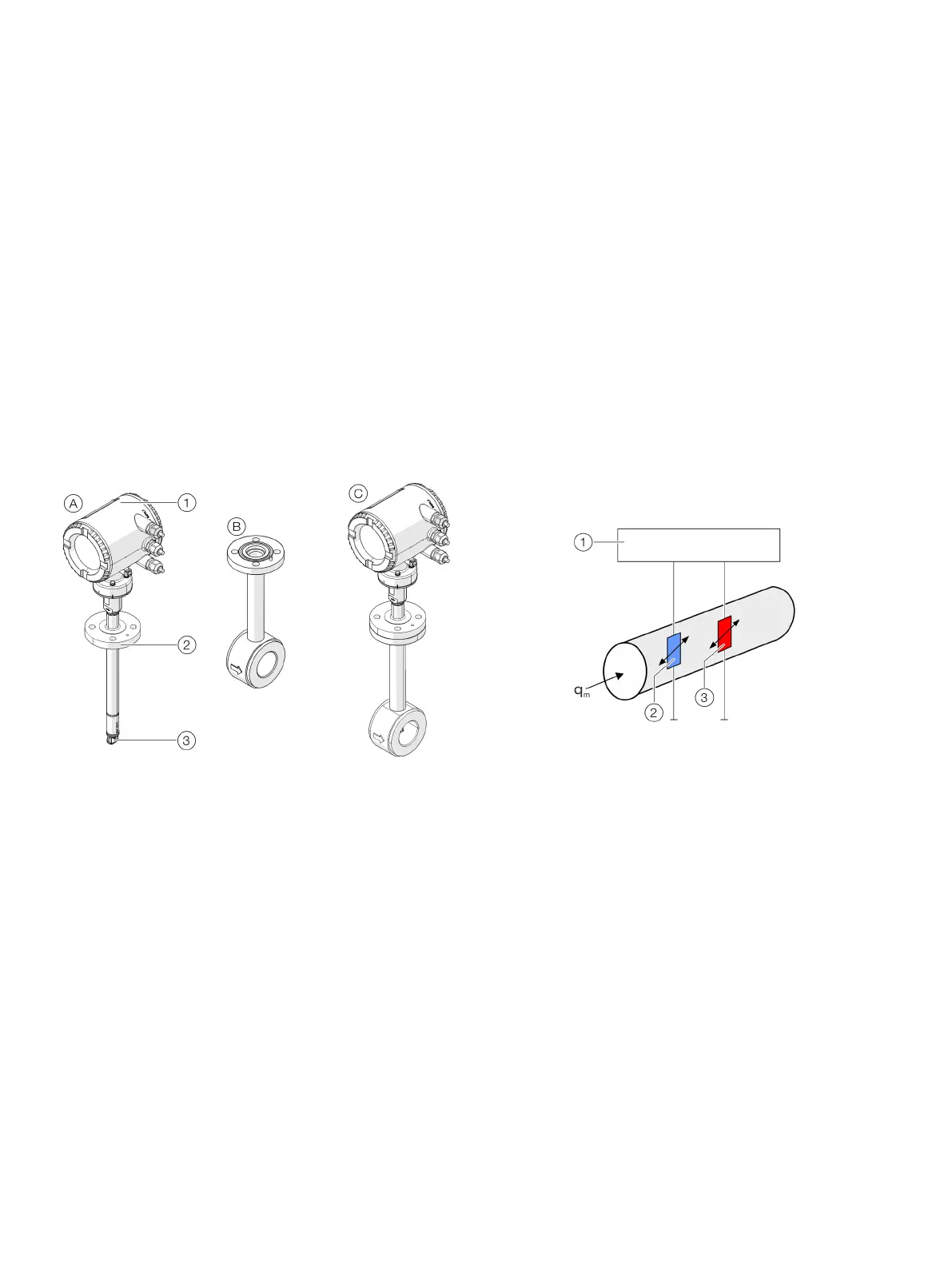

Transmitter

Gas temperature measurement

resistor

Heating resistor

Figure 9: Measuring principle (simplified)

The transmitter has three signals available. In addition to the

heating power, the temperatures of the measuring medium and

the heater resistance are included herein, which can be used to

compensate the temperature dependency of gas parameters.

By storing the gas data in the transmitter the optimal tailoring

can be calculated and performed at any operating point.

Loading...

Loading...