32 SensyMaster FMT430, FMT450 THERMAL MASS FLOWMETER | OI/FMT430/450-EN REV. B

… 6 Installation

Assembly of the pipe component

When installing the pipe components, observe the following

points:

• During installation, it is important to ensure that the flow

direction corresponds to the attached label.

• When welding the welding adapter, remember to observe

the relevant welding instructions. The amount of heat

introduced must be kept to an absolute minimum to

prevent warping of the mounting flange's sealing surface.

• In the case of flanged connections, flat gaskets must be

installed, which should be in perfect condition and

resistant to the measuring media.

• Before installing pipe components or sensors, check all

components and gaskets for damage.

• Pipe components must not be installed under tension,

otherwise the piping may exert impermissible forces on

the device.

• When assembling the flanged connections, use screws

that offer the required strength and dimensions.

• The screws must be tightened evenly and to the required

torque.

• Once the pipe components have been installed, the

insertion connection must be sealed by means of a blind

flange plus gasket or by closing a shut-off device (if

present).

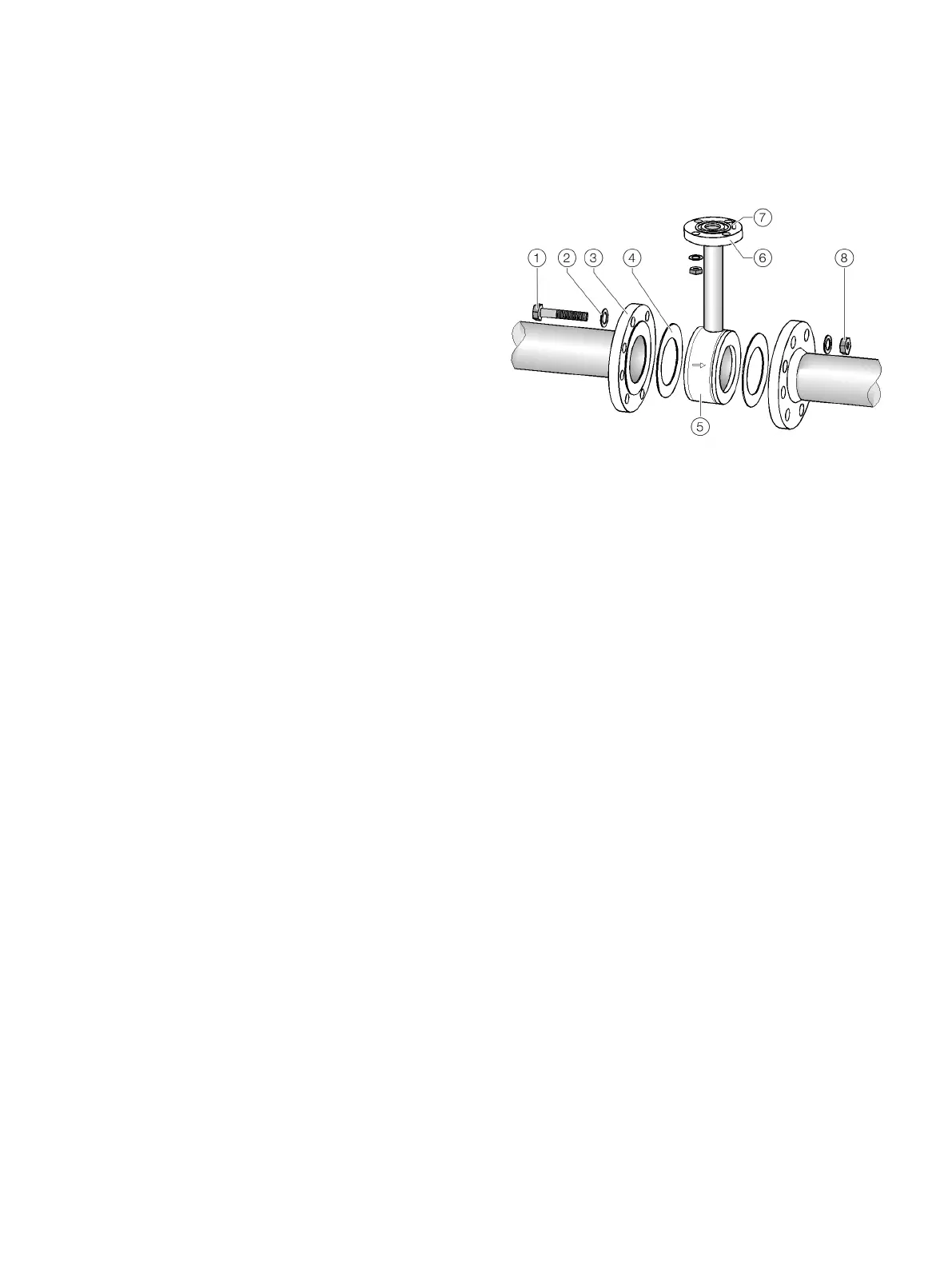

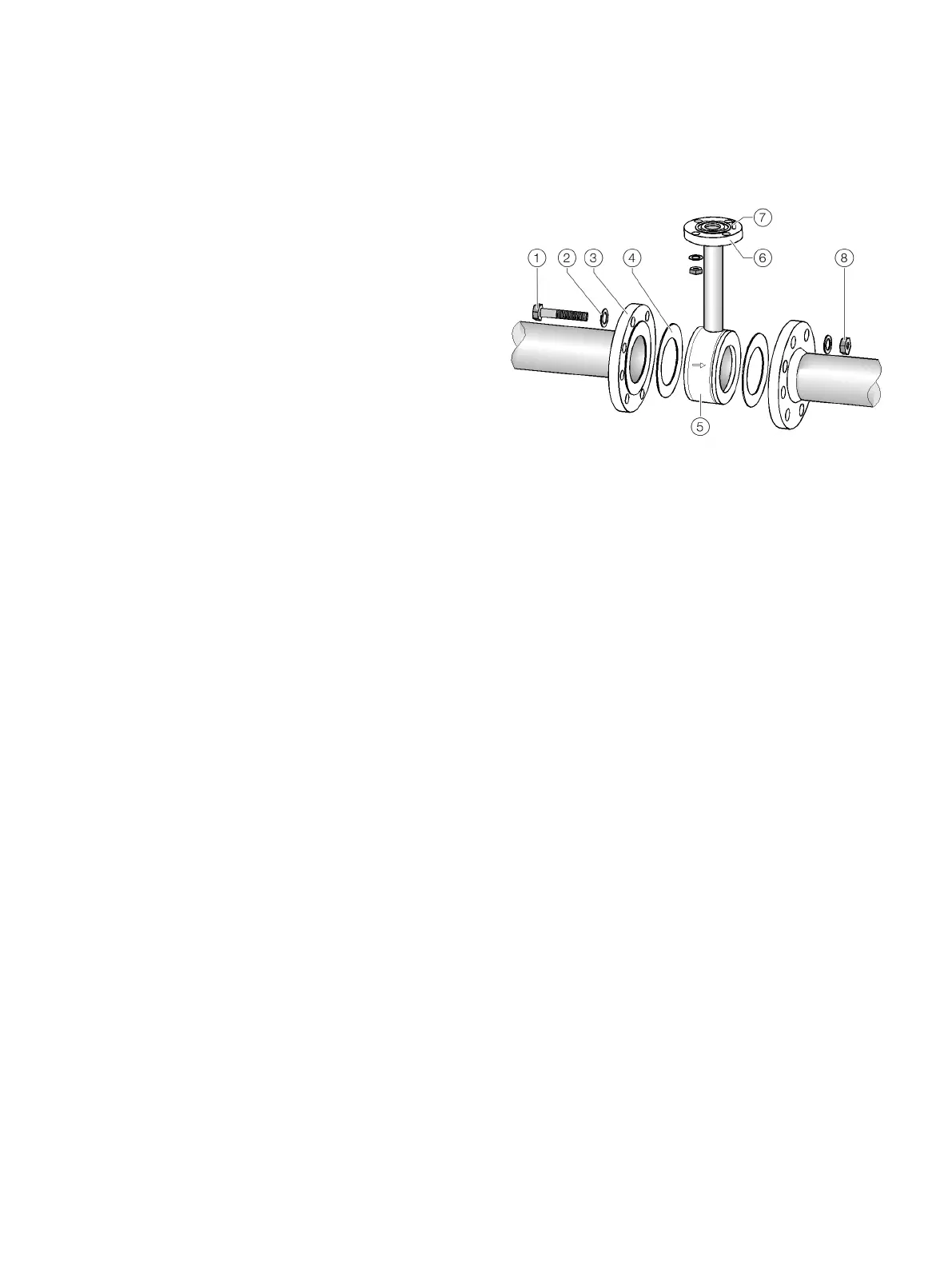

Wafer type design (FMT091) and partial

measuring section (FMT092)

Flange screw

Washer

Flange

Flange gasket

Pipe component

Sensor connection

Centering pin, outflow side

Nut

Figure 18: Installing a pipe component (example, wafer type design)

1. Position the pipe component coplanar and centered between

the piping. The flow direction must correspond to the arrow

indicated on the pipe component. The centering pin on the

pipe component must be located on the outflow side (behind

the measuring point).

2. Install gaskets between the sealing surfaces.

Note

For achieve the best measurement results, make sure the

gaskets fit concentrically with the pipe component.

• The inside diameter of the pipe and flange must precisely

match in the wafer type design. Any differences in levels or

edges, or untidy weld seams, will reduce the measuring

accuracy.

• To guarantee that the flow profile is not distorted, the

gaskets must not protrude into the piping.

Loading...

Loading...