SensyMaster FMT430, FMT450 THERMAL MASS FLOWMETER | OI/FMT430/450-EN REV. B 43

Calculation of the installation length X and installation depth Y

Outside length of the integrated changing device

Installation depth of the integrated changing device

Sensor length

Outside diameter of the pipeline

Example

• Sensor length h = 425 mm (16.73 in)

• Pipe with outside diameter of 210 mm (8.27 in)

• The hot tap fitting is in measurement position

X = 425 mm − (210 mm / 2) = 320 mm

Y = (210 mm / 2) − 28 mm = 77 mm

Consider the following points when installing the welding

version in the piping:

• Maintain a right angle to the pipe axis (max. tolerance 2°).

• The adapter centering pin must be aligned with the pipe

axis in the flow direction (outflow side, behind the

measuring point).

Damage to components

If the welded joints become hot, warping of the sealing

surfaces and / or damage to the O-rings can occur.

• Pause occasionally to allow the fitting to cool.

Impact on measuring accuracy

Deviations from the stated dimension and position tolerances

have an impact on measuring accuracy.

Installing the sensor

When installing the sensor, observe the following points:

• Installation in the pipe component or welding adapter is

only possible if the sensor data matches the measuring

point specifications.

• The sensor may be sealed only by using the O-ring

supplied in the scope of delivery. The O-ring must be

placed in the designated groove on the sensor

connection.

• The sensor elements may not be damaged when inserting

the sensor into the pipe component.

• If you are using an integrated hot tap fitting, you must

check that the hot tap fitting is in the disassembly

position before releasing the fixing screws.

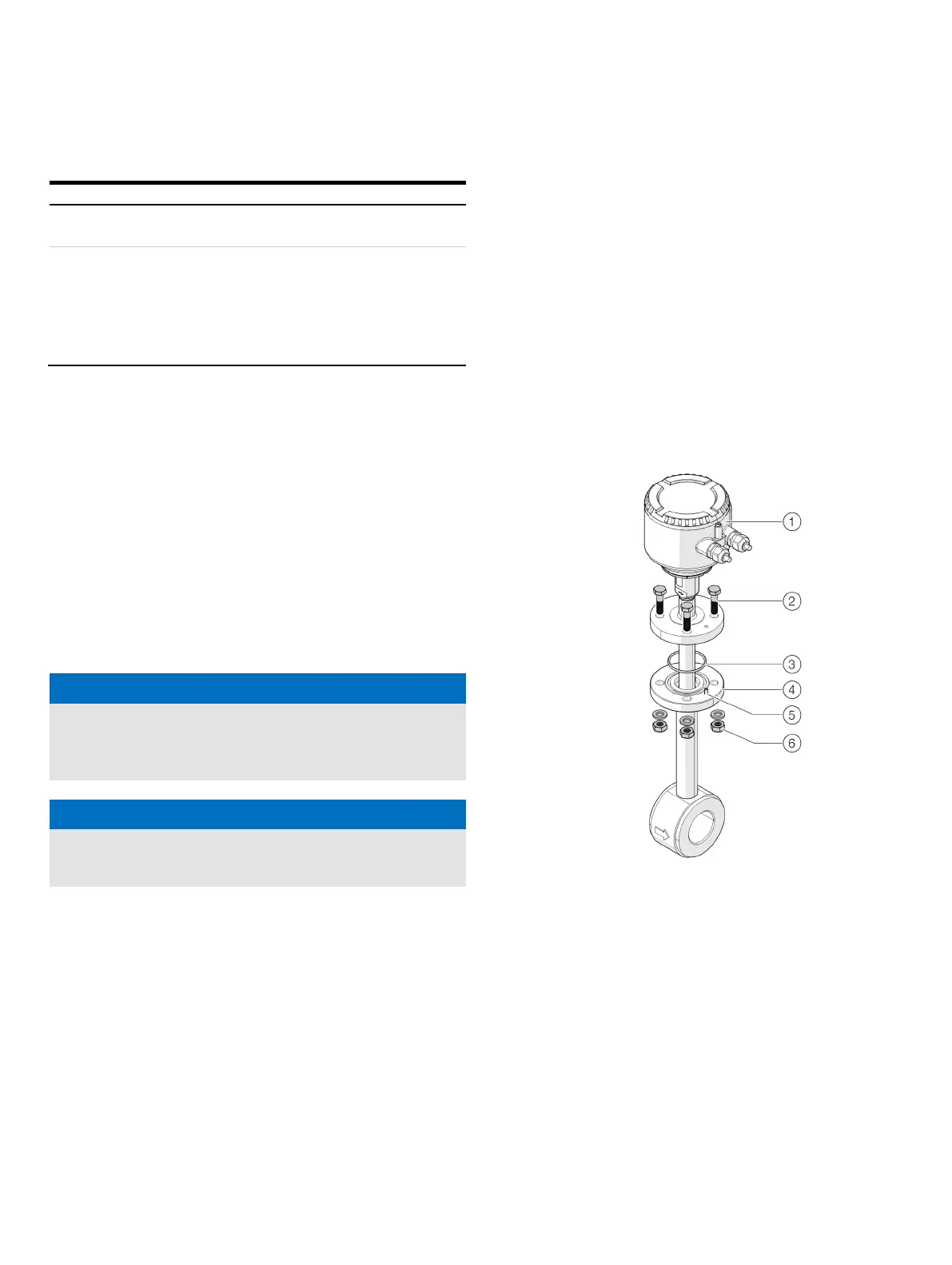

Wafer type design and welding adapter

Sensor

Flange screws

O-ring

Sensor connection

Centering pin

Washers and nuts

Figure 28: Installing a sensor (example)

Loading...

Loading...